Double-chain double-shaft gear bearing transmission structure of three-dimensional garage chain shifting plate

A technology of three-dimensional garage and transmission structure, which is applied to shafts and bearings, bearings of rotary motion, bearings, etc., can solve the problems of chain sprocket bearing damage, large wear of inner and outer guide rails, and lifting chain off-chain, etc. Wear resistance and service life, and the effect of improving synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

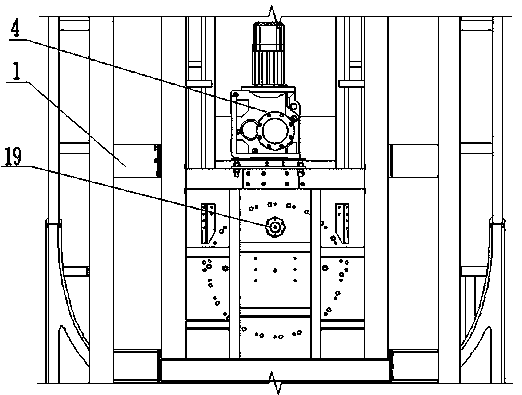

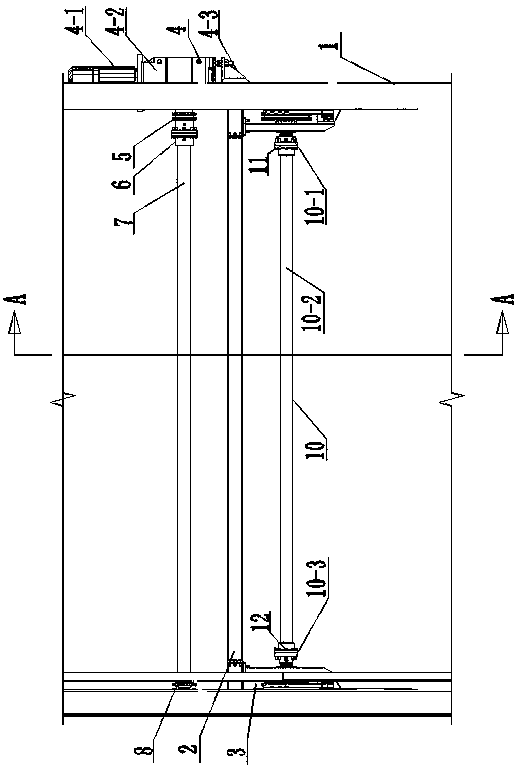

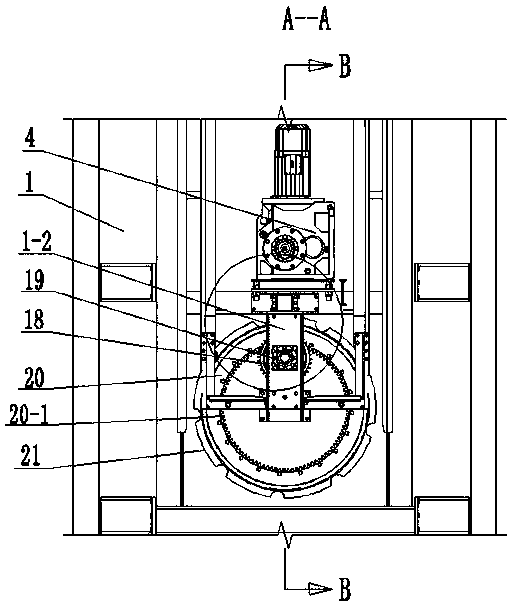

[0021] see Figure 1-Figure 4 , the present embodiment is a double-chain double-shaft gear bearing transmission structure of a vertical circulation type three-dimensional garage shifting plate, the front frame 1 and the rear frame 2 of the three-dimensional garage are arranged side by side, and the front frame 1 and the rear frame 2 are Rectangular frame structure, crossbeam 3 is installed between front frame 1 and rear frame 2, transmission shaft 10 is respectively installed between the bottom and top of front frame 1 and rear frame 2, and transmission shaft 10 is used for driving shift chain Plate 21, thereby driving the lifting chain.

[0022] The top of power transmission shaft 10 is provided with drive unit 4, and drive unit 4 is made of motor 4-1 and speed reducer 4-2, and speed reducer 4-2 is installed on the speed reducer base 4-3, on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com