Gear transmission type mechanical anti-theft lock

A mechanical anti-theft lock and gear transmission technology, applied in building locks, keys, buildings, etc., can solve the problems of high processing precision and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

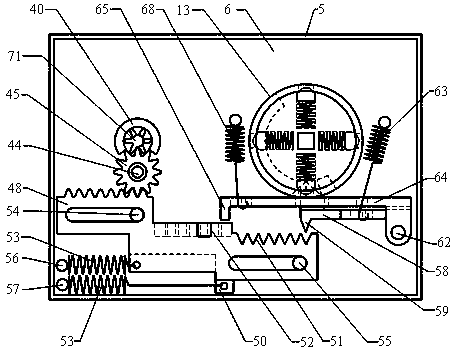

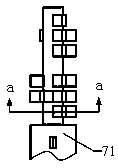

[0071] Such as figure 1 , 29 , 37, a lock body 1 of a gear transmission type mechanical anti-theft lock includes an outer plate 2, a partition plate 3, an inner plate 4 and a coaming plate 5, and the rectangular cavity between the outer plate 2 and the partition plate 3 is the outer cavity Body 6, the rectangular cavity between the partition plate 3 and the inner side plate 4 is the inner cavity body 7, the side of the outer side plate 2 that is located outside the lock body 1 is the outer side 8 of the lock body, and the side of the inner side plate 4 that is located outside the lock body 1 The side is the inner side 9 of the lock, and the inner side of the door outer panel 11 is provided with a reinforcing plate 12, the lock body 1 is fixedly mounted on the reinforcing plate 12, and the outer side 8 of the lock is in contact with the reinforcing plate 12. The outer side of the door leaf outer panel 11 is provided with a lock outer panel 69, and is assembled with a handle r...

Embodiment approach 2

[0105] Such as Figure 38 , 39As shown, the position of the parts of the unlocking control mechanism in Embodiment 1 is rearranged, the principle remains the same, and the performance of the lock remains unchanged: that is, the position of the center of the key hole remains unchanged, and it is still on the same horizontal line as the center of the cam mechanism, and is located on the cam On the left side of the mechanism, the rectangular long hole 43 is located on the top of the circular tube 40, the gear shaft 44 and the intermediate gear 45 are located directly above the circular tube 40, the left end of the rack is located above the intermediate gear 45, and the middle and right ends of the rack are located at the top of the circular tube 40. Above the cam 13, the locking plate 58 and the unlocking plate 64 are located between the right end of the rack and the cam 13, wherein the unlocking plate 64 is located under the locking plate 58 and above the cam 13, and the spring ...

Embodiment approach 3

[0108] Such as Figure 40 As shown, the following alternatives can also be adopted, the principle remains the same, and the original performance of the lock remains unchanged: the centers of the circular tube 40, the gear shaft 44, the intermediate gear 45 and the center of the cam mechanism are all placed on the same horizontal line, and each The rack runs reciprocatingly in the vertical direction, that is, the parts positions of the unlocking control mechanism are from left to right: the round tube 40 where the keyhole 41 is located, the intermediate gear 45, the vertical rack, the locking plate 58, the unlocking plate 64, The cam 13, the corresponding sliding shaft A54 and the sliding shaft B55 are respectively placed on the upper and lower parts of the outer cavity body 6, and the corresponding spring connecting posts A56 and spring connecting posts B57 are also placed on the upper and lower parts of the outer cavity body 6 respectively. The straight rack parts of A48 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com