A hydraulic pump plunger with small flow pulsation

A technology of flow pulsation and hydraulic pumps, which is applied to components, pumps, pump components, etc. of pumping devices for elastic fluids, can solve the problems of reducing the efficiency of plunger pumps, pump pressure fluctuations, pressure fluctuations, etc., to ensure the use of Effects of life, inertial force reduction, and mass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

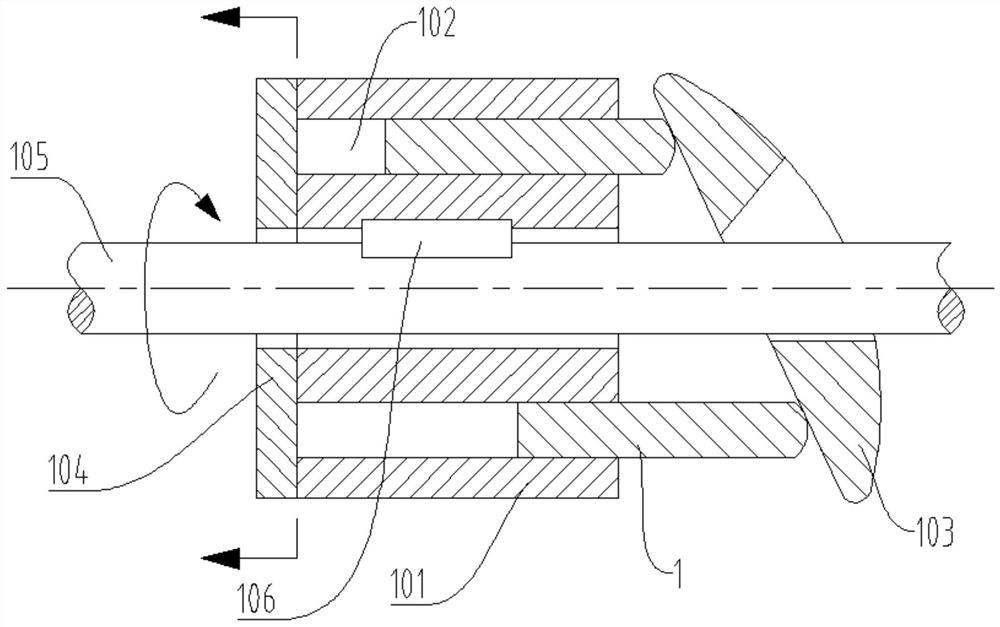

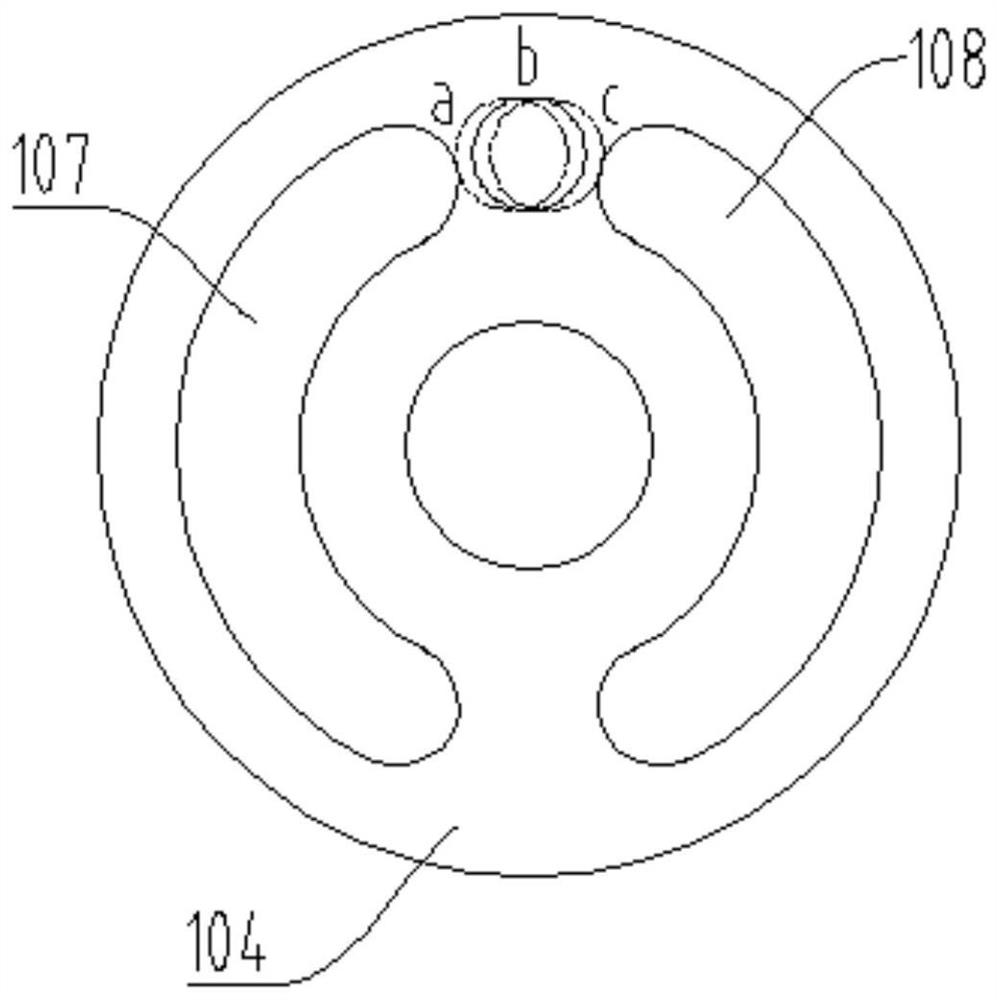

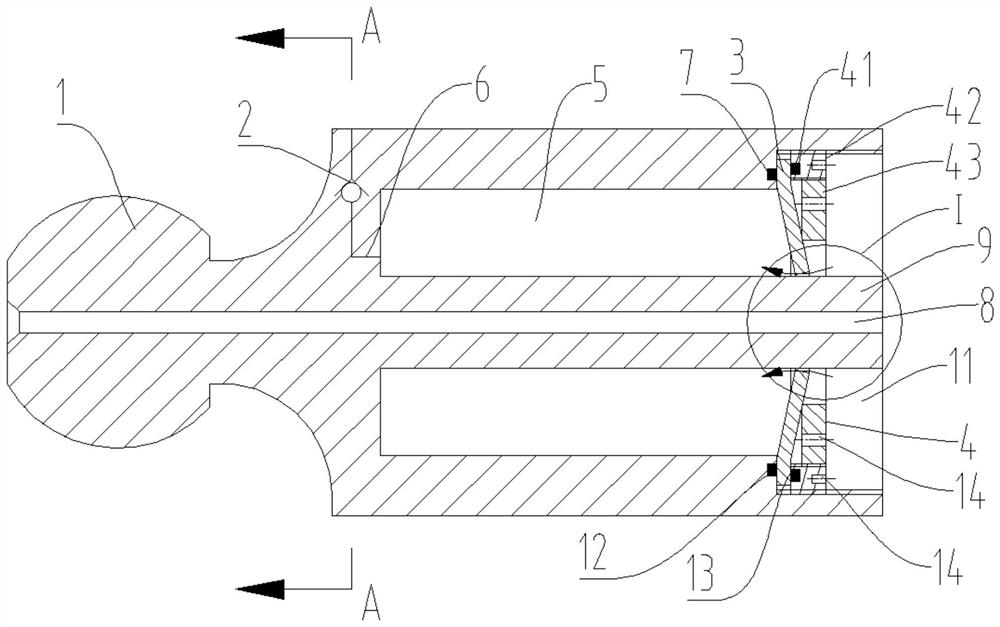

[0024] like Figure 1 to Figure 5 As shown, a plunger for a hydraulic pump with small flow pulsation includes a plunger body 1, and a central through hole 8 penetrating left and right is arranged inside the plunger body 1. The active part is processed with an annular accommodation chamber 5 arranged around the central through hole 8, the opening of the annular accommodation chamber 5 is located on the right end surface of the plunger body 1, and the plunger body 1 is between the annular accommodation chamber 5 and the central through hole 8 The part between them forms a central column 9, and the plunger body 1 is provided with an outwardly expanding annular installation cavity 11 at the right end of the annular accommodation cavity 5; Oil channel 6;

[0025] The inner surface of the annular installation cavity 11 is provided with an internal thread A, and the bottom plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com