Anti-impact vibration reduction structure and vibration reduction system for micro-inertia measurement unit

A technology of micro-inertial measurement and vibration-damping structure, which is applied in directions such as navigation through velocity/acceleration measurement, which can solve the problems of large installation space and achieve the effect of simple assembly, good vibration effect, and multiple attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

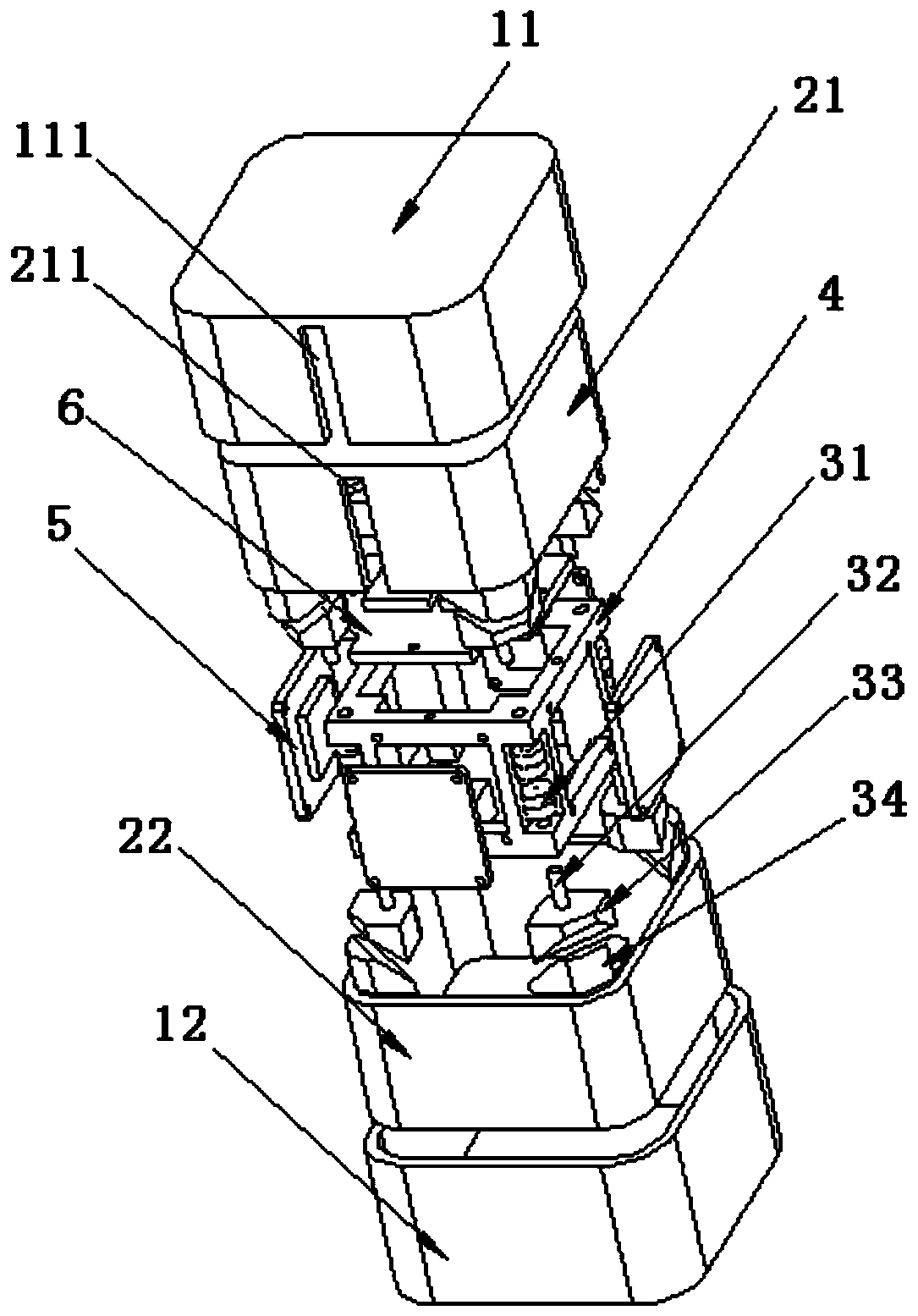

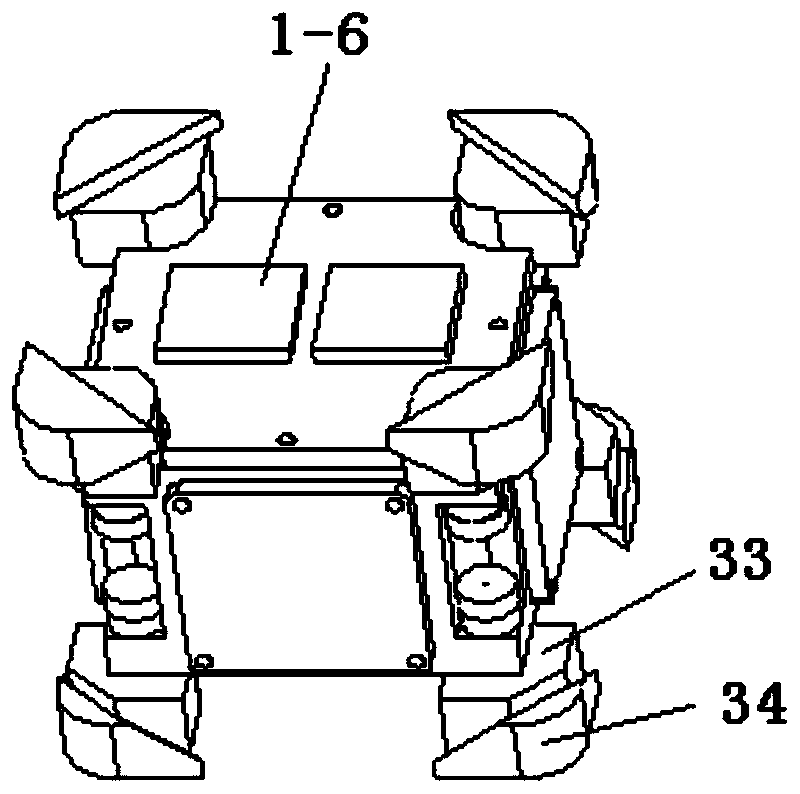

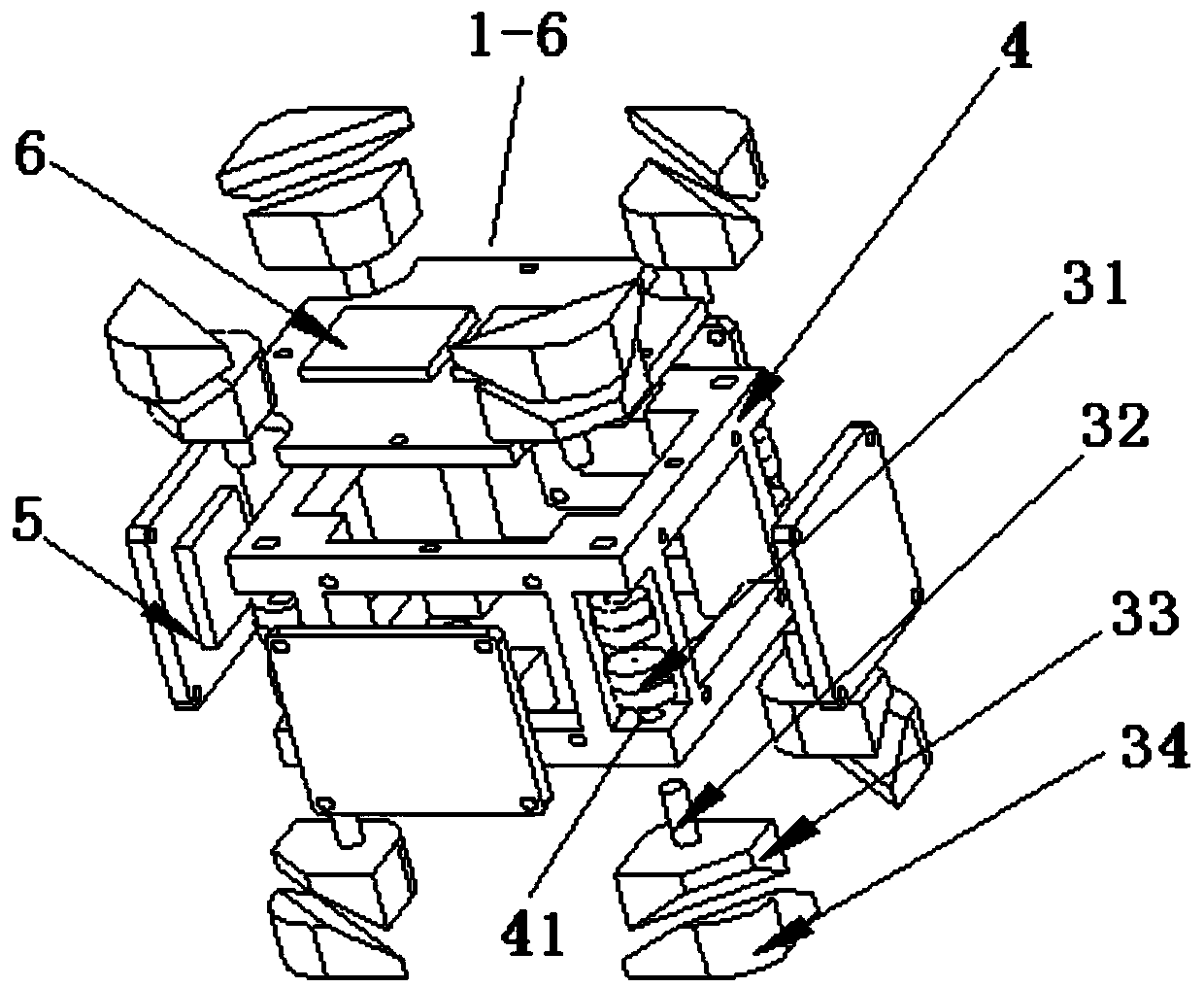

[0066] Such as figure 1 - image 3 As shown, the anti-shock and vibration-damping structure of the micro-inertial measurement unit in this embodiment is used for anti-shock and vibration-damping micro-inertial modules 1-6, including a vibration isolator arranged on a metal support frame 4, a vibration isolator And micro-inertia module 1-6 outside has the metal shell 21,22 that is set up and can accommodate these parts space. The micro-inertial modules 1-6 mainly include a MEMS sensor circuit board 5 and a processor circuit board 6 assembled on a metal support frame 4 .

[0067] In order to realize the inertial parameter measurement of six degrees of freedom, the metal support frame 4 used for assembling the inertial measurement circuit is an approximate hexahedral frame structure to ensure the orthogonality of the measurement coordinate system. The four supporting columns of the hexahedral frame structure are designed to be chamfered inwardly, and the upper top and lower bot...

Embodiment 2

[0071] Such as figure 1 - Figure 4 As shown, on the basis of Embodiment 1, the anti-shock and vibration reduction system of the inertial measurement unit in this embodiment includes: the load-bearing fully-enclosed buffer pads 11, 12 arranged outside the micro-inertial modules 1-6, and the micro-inertia modules 1-6. The inertial modules 1-6 are installed in the base and play a protective impact-resistant protective shell 8 and a cover plate 7 and the like.

[0072] Vibration isolation or attenuation is carried out inside the micro-inertia module, and a load-bearing fully-enclosed buffer pad 11, 12 is respectively set on the two mated metal shells 21, 22 outside the micro-inertia module, so that the micro-inertia module and Measures against high overload impacts are formed between the impact-resistant protective shells 8 .

[0073]The high overload shock that the micro inertial module is concerned about usually occurs during the launch process of the carrier. It is an accele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com