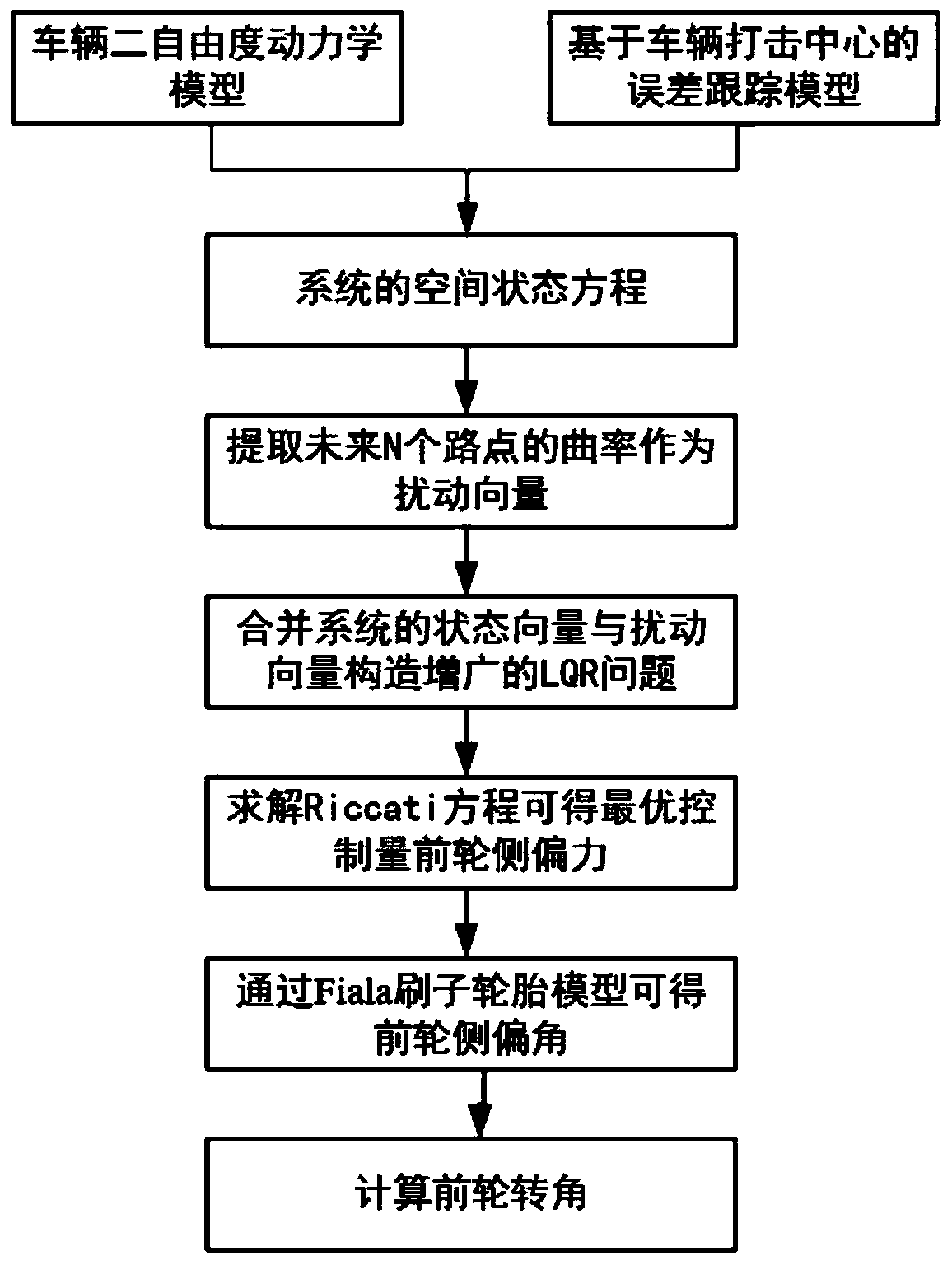

Multipoint pre-aiming LQR transverse control method based on Fiala brush tire model

A tire model, lateral control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as deviation from the desired path and vehicle instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

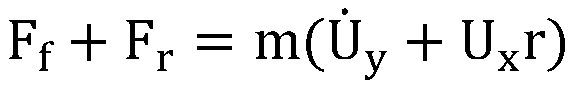

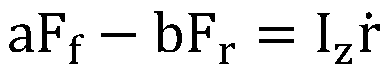

[0075] As an improved specific implementation, the vehicle two-degree-of-freedom dynamics model in the step 1 is:

[0076]

[0077]

[0078] In the formula, F f is the cornering force of the front wheel, F r is the rear wheel cornering force, m is the mass of the vehicle, U y and U x are the lateral velocity and longitudinal velocity, r is the yaw rate of the vehicle, a and b are the distances between the front axle, the rear axle and the center of mass of the vehicle, respectively, I z is the steering moment of inertia of the vehicle. Through the above method, the two-degree-of-freedom dynamic model of the vehicle can be effectively constructed, and the model is related to each basic parameter data of the vehicle, so that the model can accurately reflect the specific situation of the vehicle. .

[0079] As an improved specific implementation, the tracking error model based on the vehicle strike center in the step 1 is:

[0080]

[0081]

[0082]

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com