Superconducting conductor bracket with high heat dissipation efficiency

A superconducting conductor, high heat dissipation technology, applied in superconducting/high conducting conductors, the usage of superconducting elements, superconducting devices, etc., can solve the problems of slow cooling speed, low efficiency, inability to dissipate heat in time by cables, etc. Small influence, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

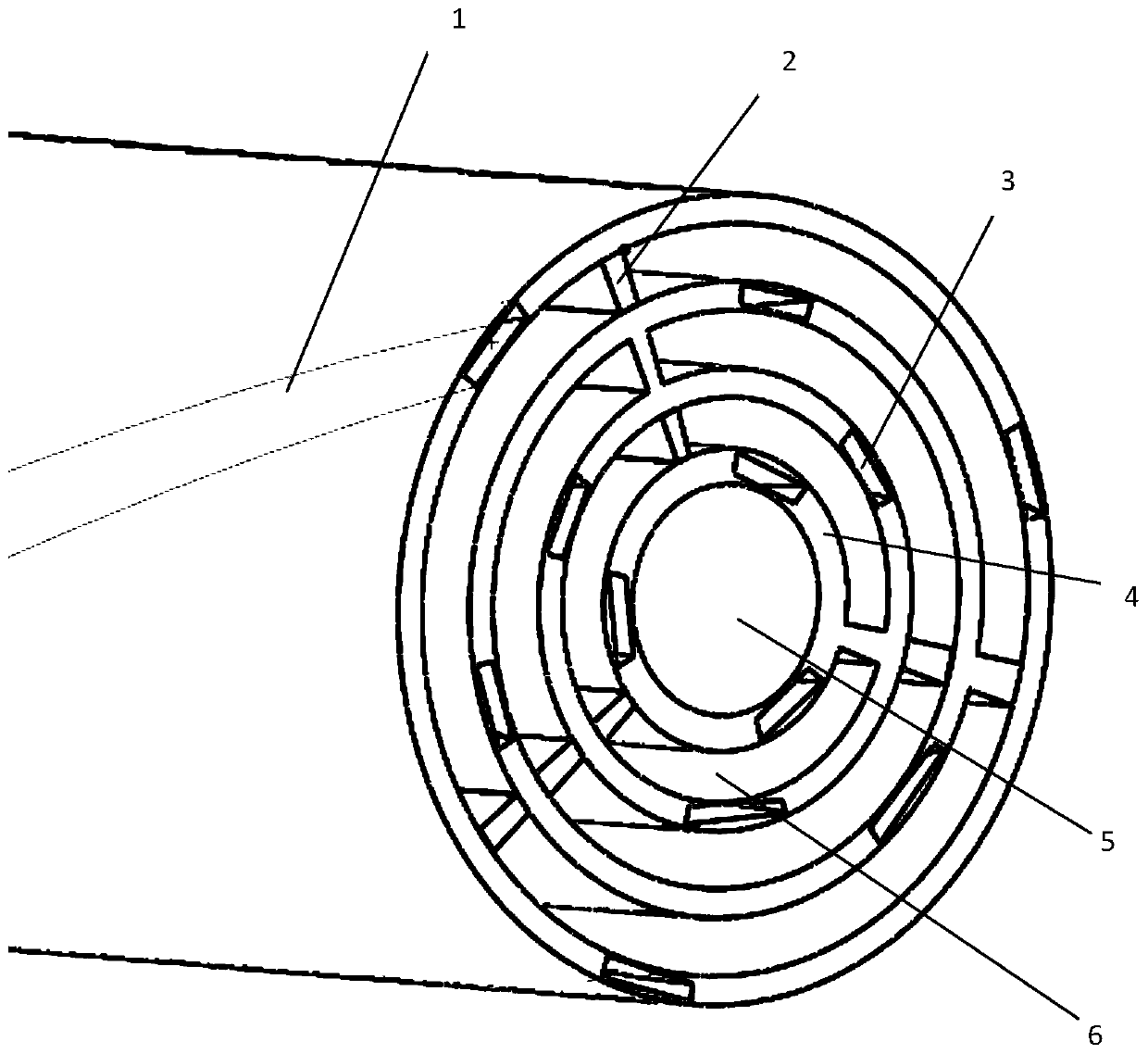

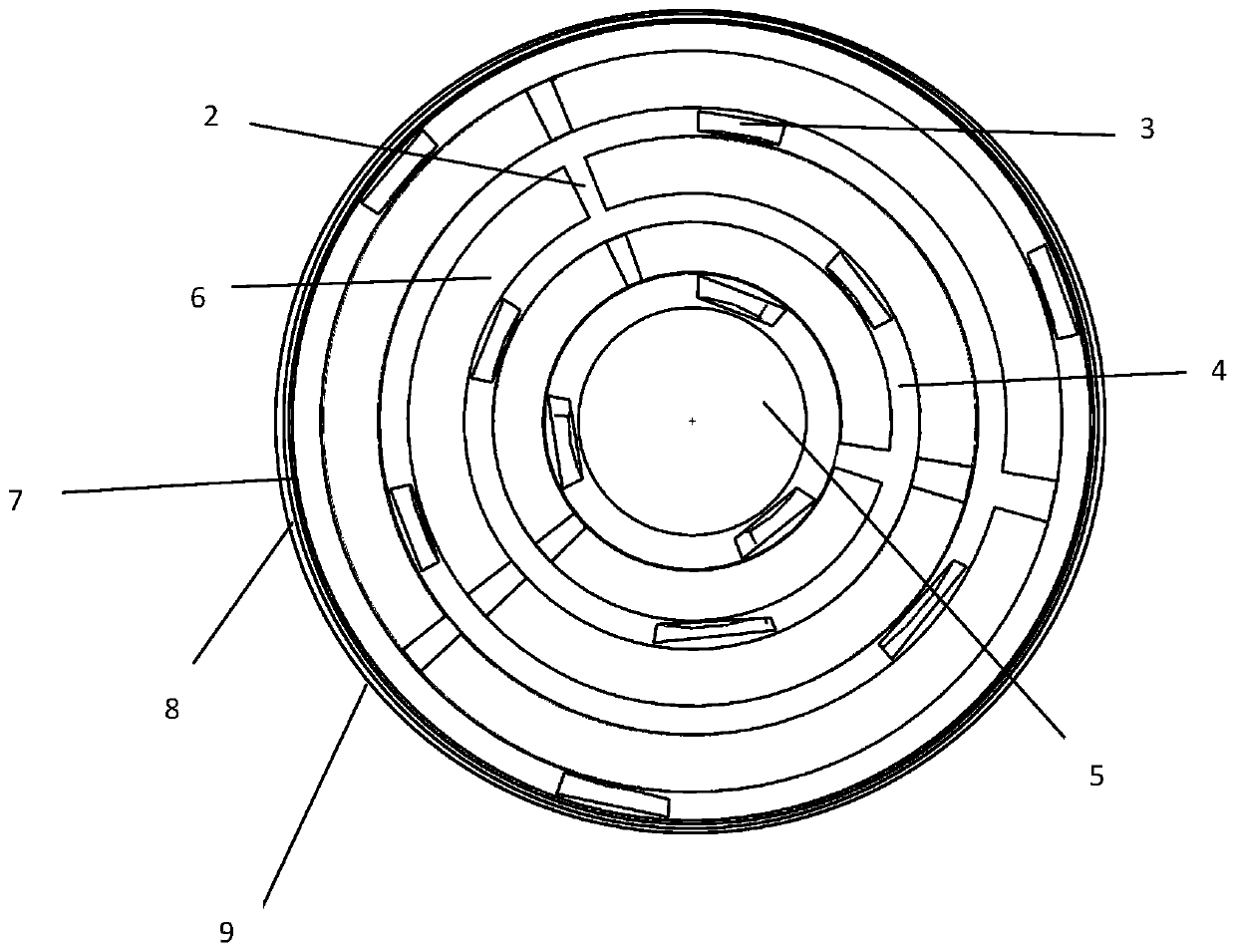

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 , 2 As shown, a superconducting conductor support with high heat dissipation efficiency includes an overall support frame 4 and an interlayer support body 2, and the overall support frame 4 includes several layers of cylindrical walls made of metal materials with a certain thickness, On each layer of the cylinder wall, there are circumferentially symmetrical superconducting conductor passages 3; the central hollow of the overall support frame 4 is the central cooling passage 5; the interlayer support body 2 is made of metal material, located Between the adjacent two-layer cylindrical walls, it is used to support the cylindrical walls, so that there is a certain space between the adjacent two-layer cylindrical walls. The adjacent two-layer cylindrical walls of the overall support frame 4 and the layer The support body 2 forms several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com