A kind of nitrogen-doped carbon catalyst and its preparation method and application

A nitrogen-doped carbon and catalyst technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as homogeneous doping of difficult nitrogen atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A method for preparing a nitrogen-doped carbon catalyst, the method comprising the steps of:

[0062] 1) The triaryl imidazole benzoxazine monomer (TBZ) is placed in a reactor for thermal polymerization to obtain a triaryl imidazole benzoxazine polymer (TPB).

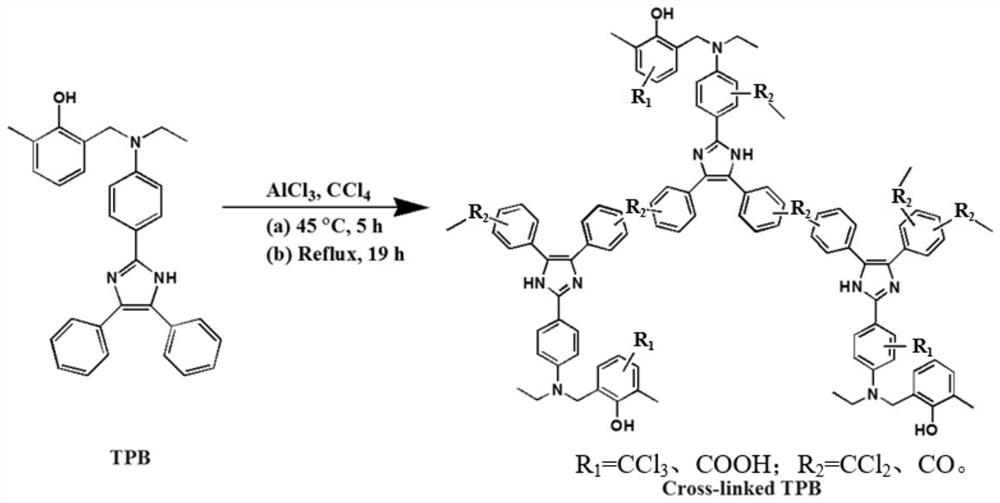

[0063] 2) The triaryl imidazole benzoxazine polymer (TPB) obtained in step 1) is subjected to a Friedel-Crafts reaction in the presence of a catalyst and a crosslinking agent to synthesize a triaryl imidazole benzoxazine crosslinked polymer (Cross -linked TPB).

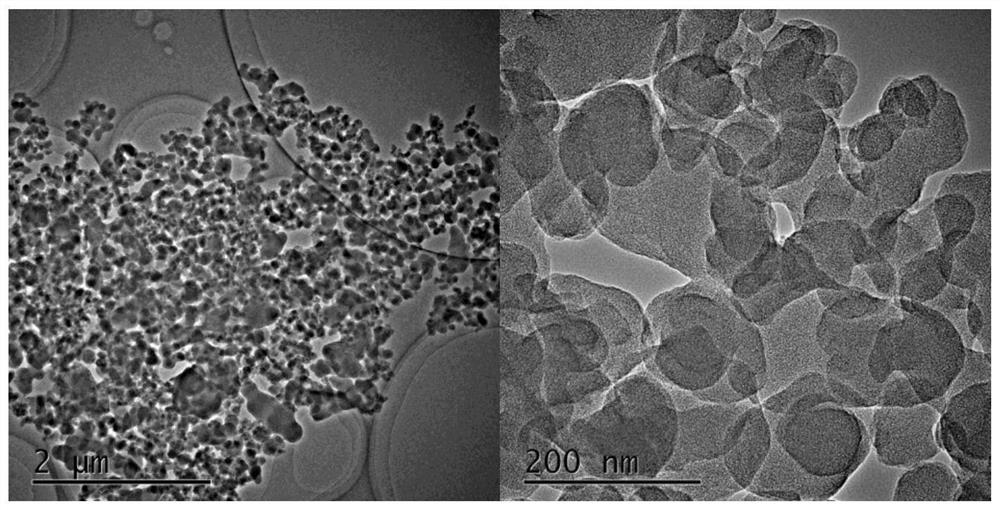

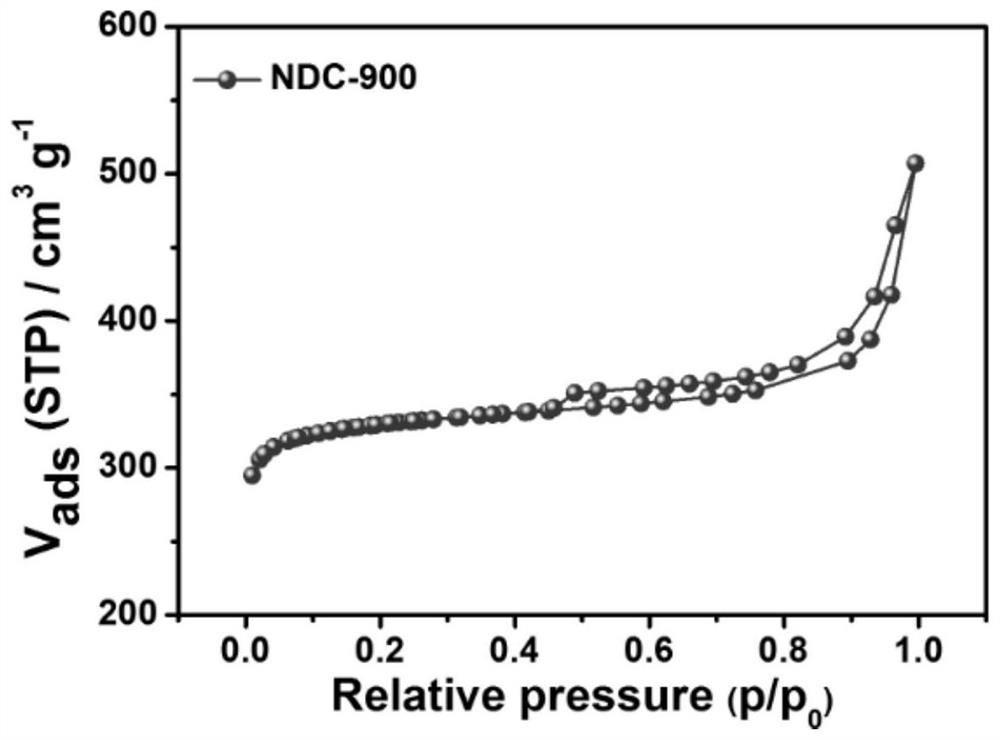

[0064] 3) The nitrogen-doped carbon catalyst (NDC) is obtained by heat-treating and acid-treating the triarylimidazole-containing benzoxazine cross-linked polymer (Cross-linked TPB) obtained in step 2).

[0065] Preferably, step 1) specifically includes: putting the triaryl imidazole benzoxazine monomer (TBZ) into a reactor (such as a muffle furnace), and then raising the temperature of the reactor to perform the reaction (the reaction temperature is 15...

Embodiment 1

[0071] 1) Synthesis of triaryl imidazole benzoxazine monomer (TBZ):

[0072] Synthesis of compound A (2-{[4-(4,5-diphenyl-1H-imidazol-2-yl)-phenylimino]-methyl}-phenol): Weigh 10g (32mmol) of 4 -(4,5-Diphenyl-1H-imidazol-2-yl)-aniline and 5.52g (48mmol) of salicylaldehyde were dissolved in 300ml of ethanol, and then heated to 100°C under nitrogen atmosphere for reflux reaction for 24h. After the reaction, the system was poured into 1000ml petroleum ether, suction filtered and washed to obtain bright yellow compound A with a yield of 95%.

[0073] Synthesis of compound B (2-{[4-(4,5-diphenyl-1H-imidazol-2-yl)-phenylamino]-methyl}-phenol): add 1.67 g (43.2mmol) sodium borohydride, 9g (21.6mmol) compound A and 100ml dry tetrahydrofuran were stirred at room temperature for 12h. After the reaction, slowly add 70ml of water, continue to stir for 12h, then pour the system into a large amount of cold water, and filter with suction. The obtained product was first dried under vacuum ...

Embodiment 2

[0082] 1) Synthesis of triaryl imidazole benzoxazine monomer (TBZ):

[0083] Synthesis of compound A (2-{[4-(4,5-diphenyl-1H-imidazol-2-yl)-phenylimino]-methyl}-phenol): Weigh 10g (32mmol) of 4 -(4,5-Diphenyl-1H-imidazol-2-yl)-aniline and 5.52g (48mmol) of salicylaldehyde were dissolved in 300ml of ethanol, and then heated to 100°C under nitrogen atmosphere for reflux reaction for 24h. After the reaction, the system was poured into 1000ml petroleum ether, suction filtered and washed to obtain bright yellow compound A with a yield of 95%.

[0084] Synthesis of compound B (2-{[4-(4,5-diphenyl-1H-imidazol-2-yl)-phenylamino]-methyl}-phenol): add 1.67 g (43.2mmol) sodium borohydride, 9g (21.6mmol) compound A and 100ml dry tetrahydrofuran were stirred at room temperature for 12h. After the reaction, slowly add 70ml of water, continue to stir for 12h, then pour the system into a large amount of cold water, and filter with suction. The obtained product was first dried under vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com