Laser silver removing machine and automatic parallel silver removing method of dielectric filter

A dielectric filter and laser technology, applied to waveguide devices, electrical components, circuits, etc., can solve problems such as low work efficiency, high energy consumption, unstable grinding, etc., and achieve high work efficiency, high removal accuracy, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

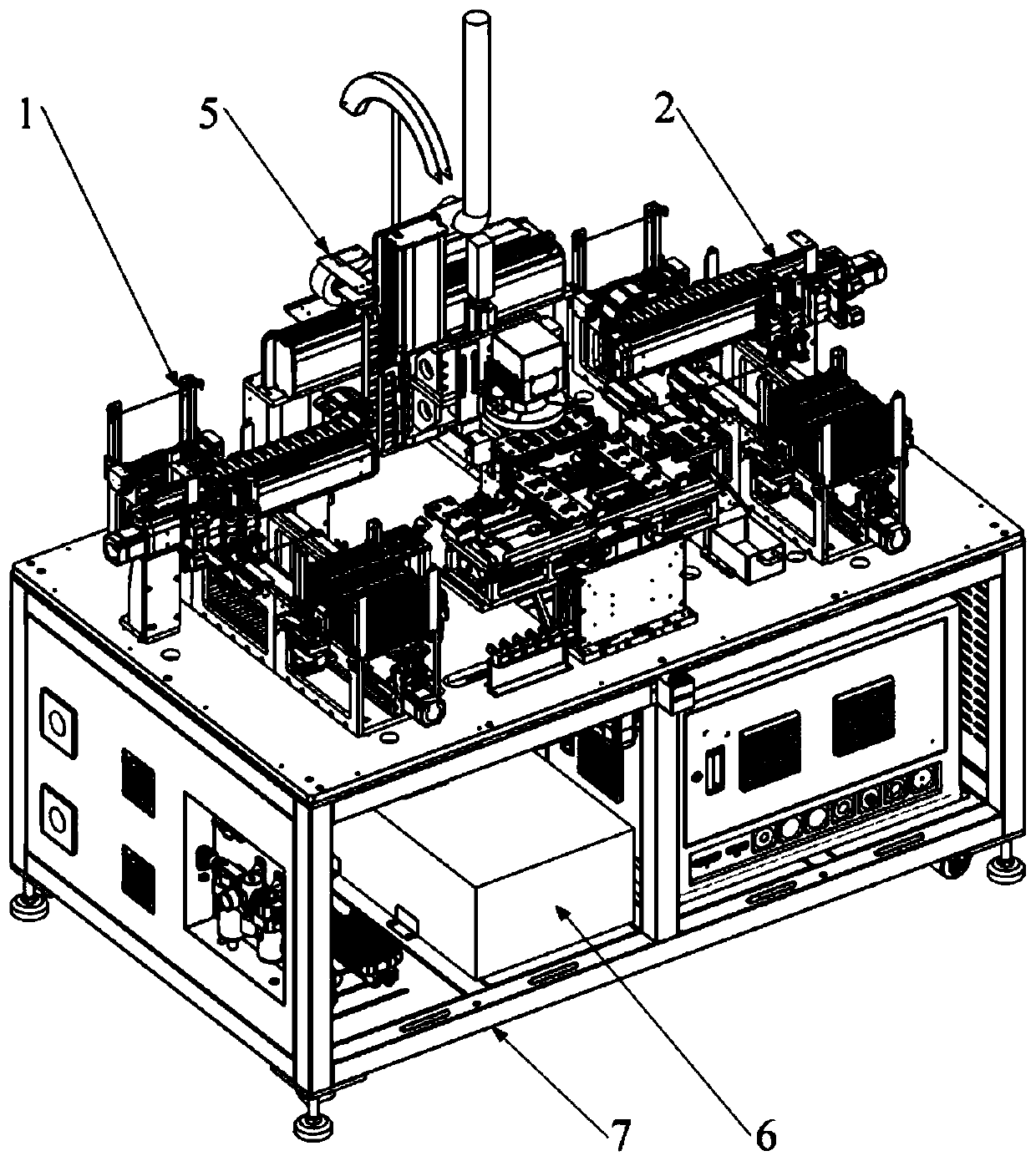

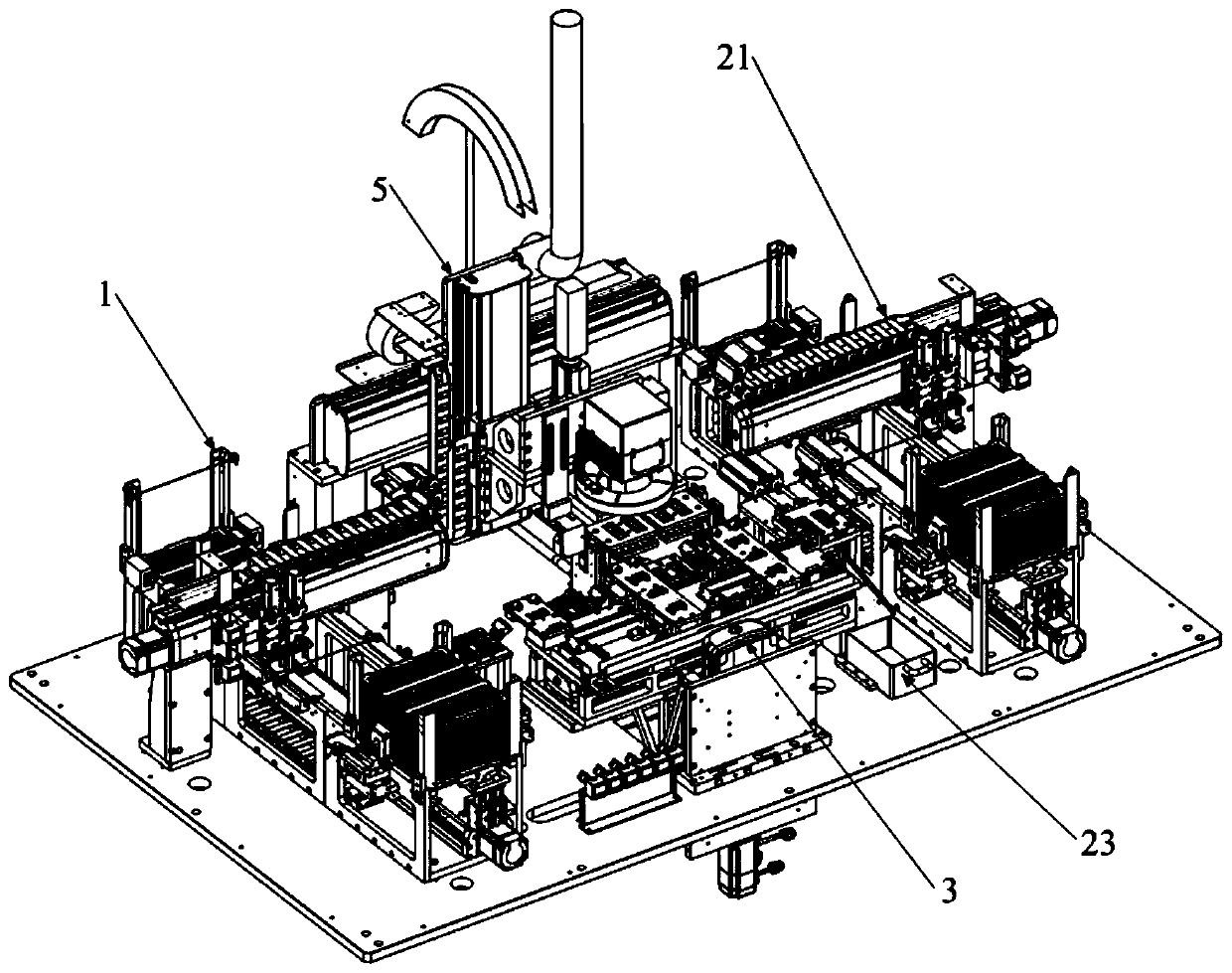

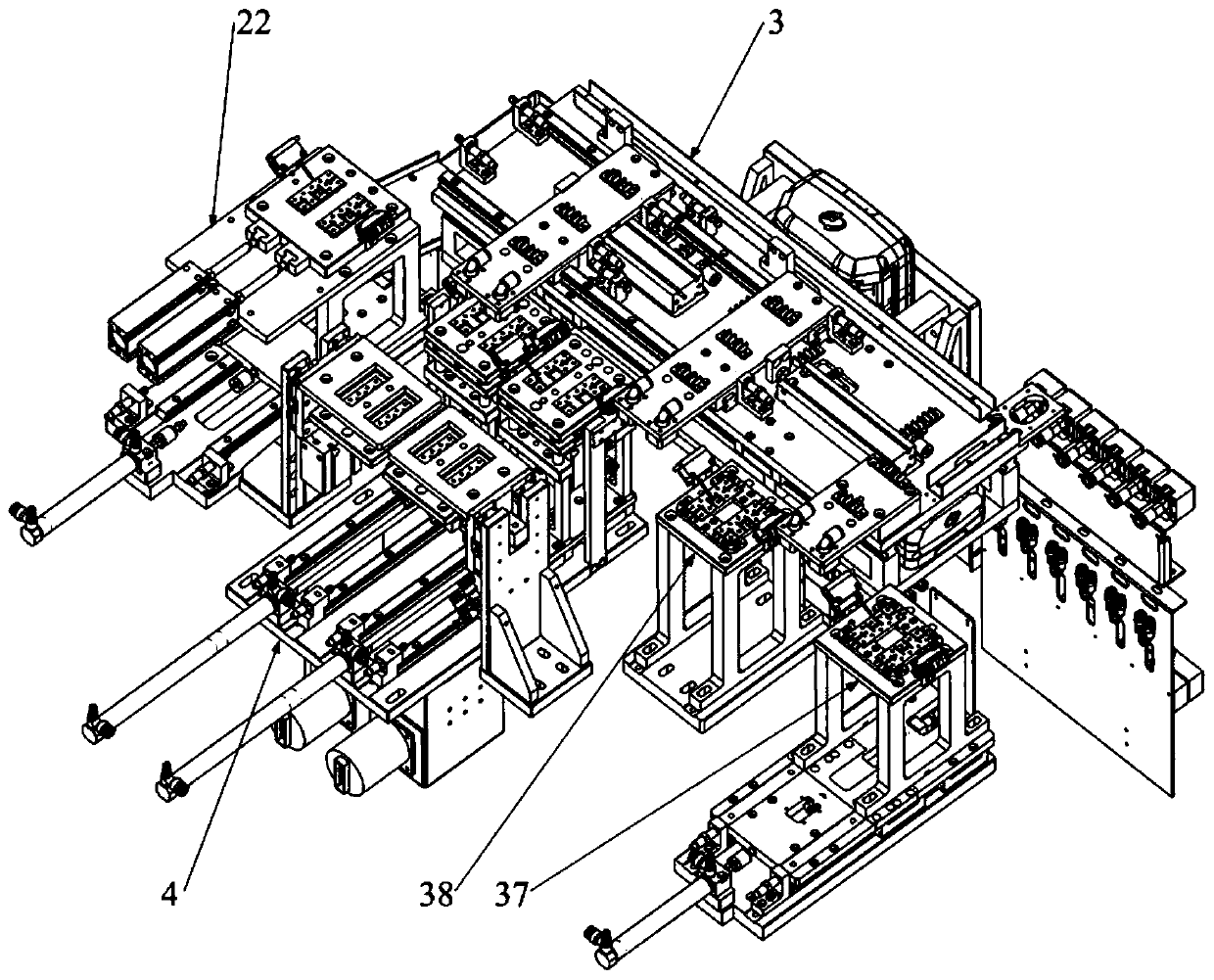

[0064] refer to Figures 1 to 9 As shown, the present invention provides a laser desilvering machine for a dielectric filter, comprising a loading mechanism 1, a blanking mechanism 2, a material transfer mechanism 3, a clamp mechanism 4, a laser desilvering mechanism 5, a network analyzer 6, and A radio frequency switcher electrically connected to the network analyzer 6; the loading mechanism 1 and the unloading mechanism 2 are arranged in parallel and at intervals, and the material transfer mechanism 3 is arranged between the loading mechanism 1 and the unloading mechanism 2; the laser The silver removal mechanism 5 is arranged on one side of the material transfer mechanism 3, and the clamp mechanism 4 is arranged between the material transfer mechanism 3 and the laser silver removal mechanism 5; the feeding mechanism 1 is used to place a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com