Compressed air power vehicle gas supply station based on vacuum pipeline transportation vacuum pump station and its operation method

A technology of aerodynamic vehicles and vacuum pipelines, which is applied to motor vehicles, roads, rails, etc., can solve the problems of increased vehicle load, high energy consumption per unit of gas production, and long gas filling time, so as to improve vacuum pumping efficiency and reduce comprehensive Cost, the effect of improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

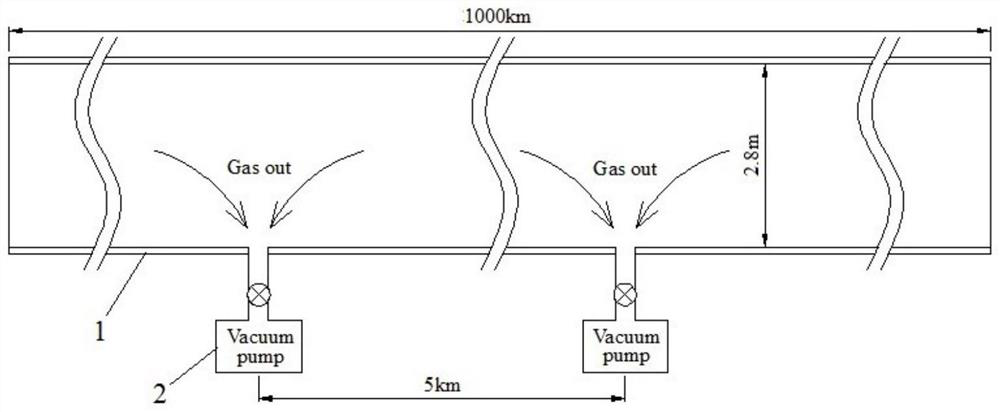

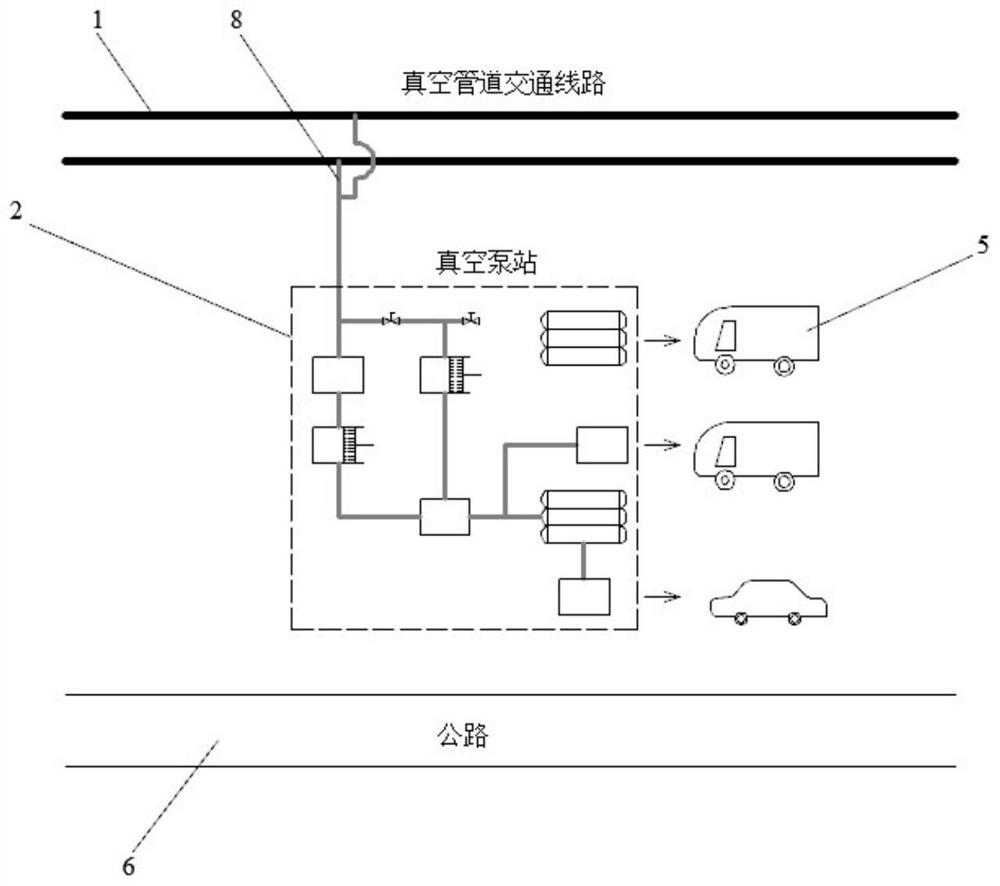

[0044] Such as figure 2 Shown, the present invention is based on the compressed air power vehicle gas supply station of vacuum pipeline traffic vacuum pumping station and comprises vacuum pipeline 1, and vacuum pumping station 2 is compressed air station, gas supply station, aerodynamic vehicle 5, road 6, air extraction pipeline 8, construction For the vacuum pipeline 1, a vacuum pumping station 2 is planned and constructed along the line. The vacuum pipeline 1 is laid along the road 6 or next to the road 6 , or along the central isolation zone of the road 6 . Thus, the vacuum pipeline traffic vacuum pumping station 2 becomes a compressed air station with the function of supplying air to the aerodynamic vehicle 5, that is, an air supply station.

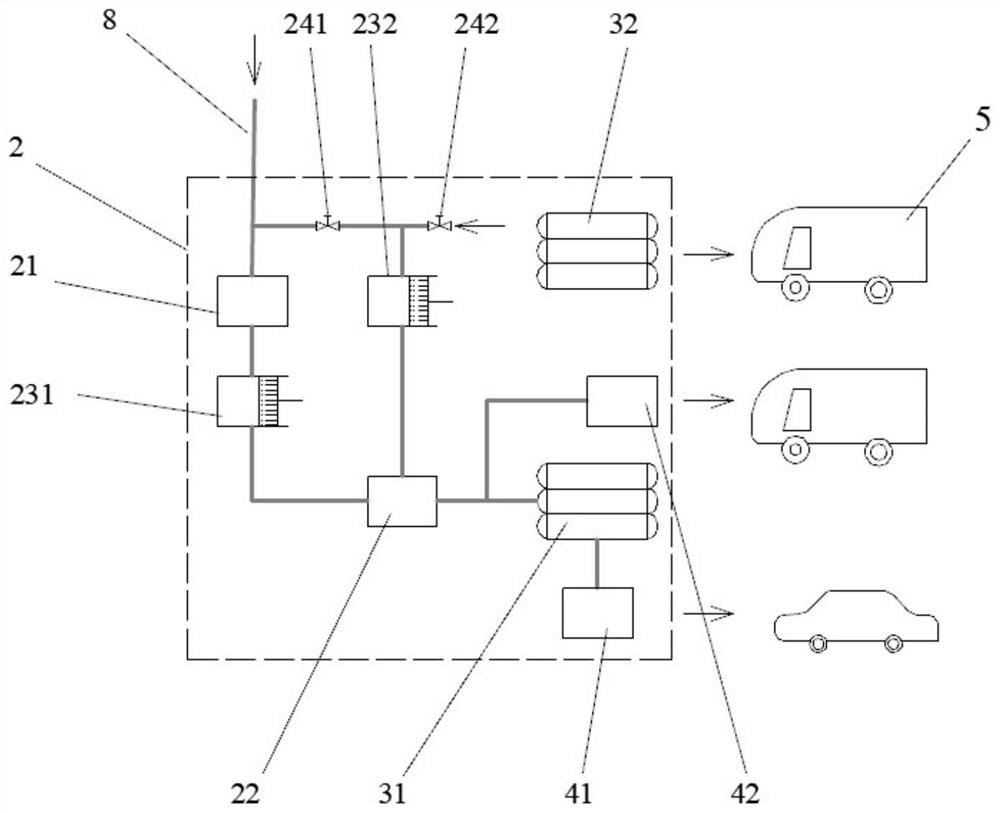

[0045] Such as image 3 As shown, the vacuum pump station 2 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com