An automatic silkworm raising machine

An automatic, motor-driven technology, applied in the direction of conveyor objects, packaging, loading/unloading, etc., can solve the problems of restricting production efficiency and market competition, large demand for manual labor, time-consuming and labor-intensive manual labor, etc., to save manual labor cost, increase the efficiency of silkworm rearing, and reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

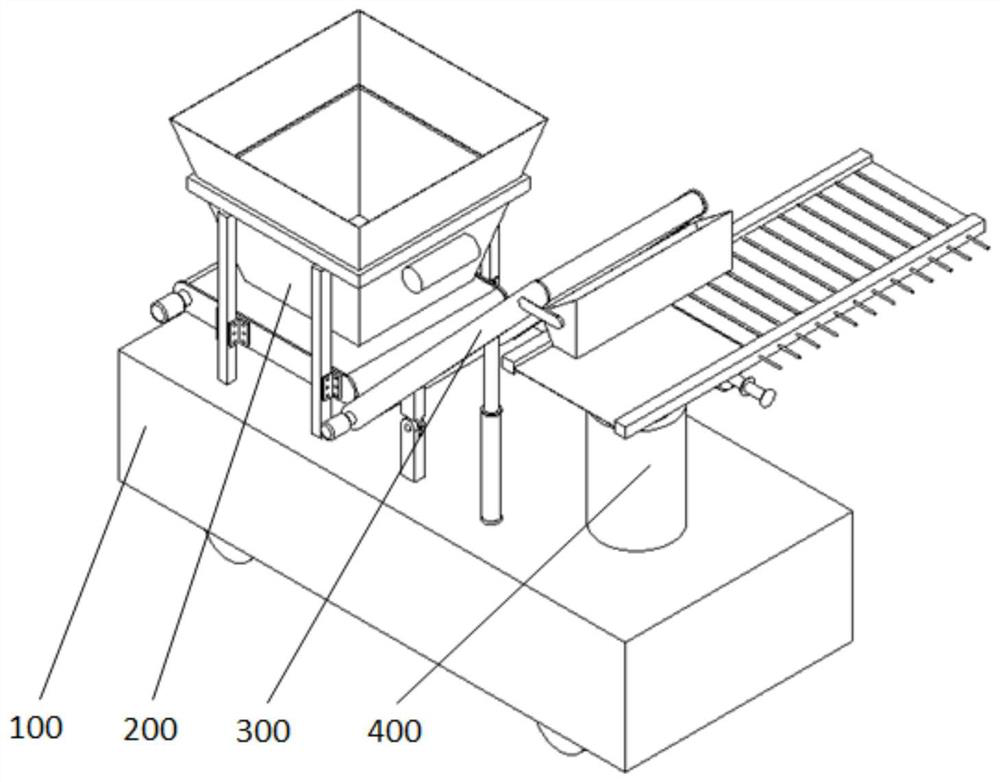

[0020] Such as figure 1 Shown, a kind of automatic sericulture machine is made up of automatic driving trolley 100, first conveying device 200, second conveying device 300 and unloading device 400; All are fixedly placed on the top of the self-driving trolley 100.

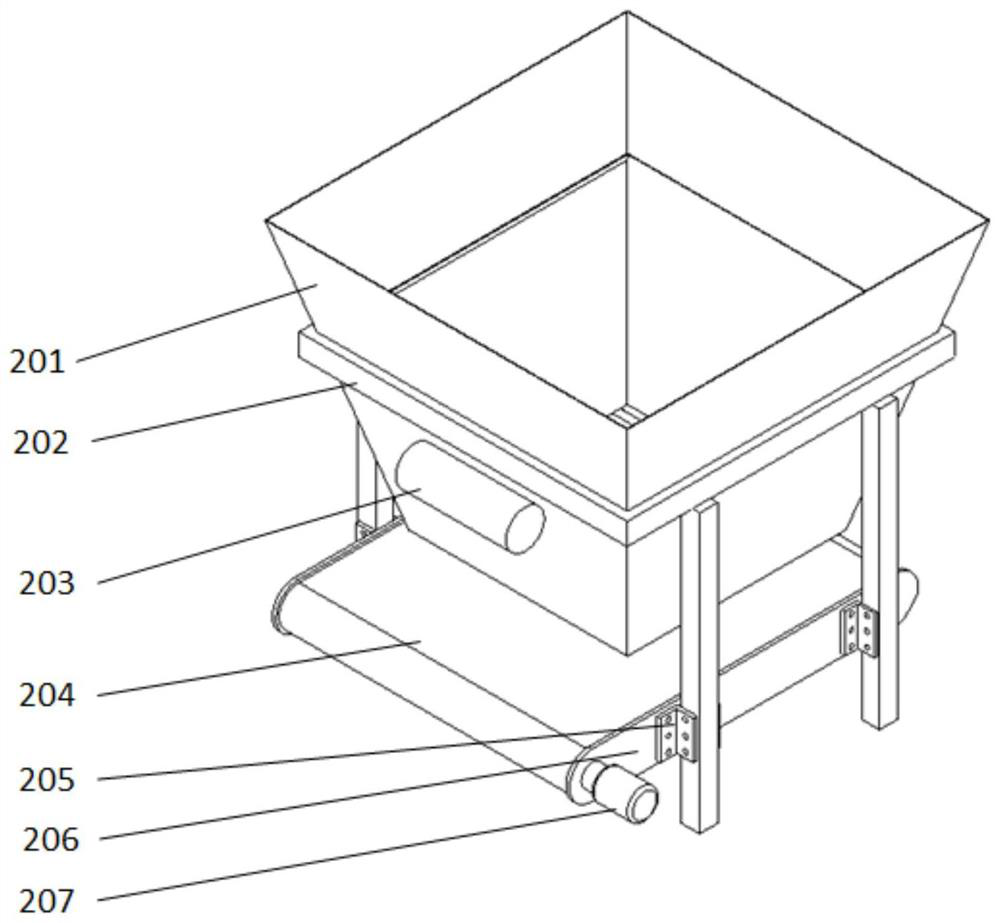

[0021] Such as figure 2 As shown, a kind of automatic sericulture machine, the first conveying device 200 is made up of hopper 201, support frame 202, vibration unit 203, horizontal conveyor belt 204, connecting block 205, horizontal conveyor belt side baffle 206, first drive motor 207; The frame 202 is fixedly connected with the self-driving trolley 100, the hopper 201 is mounted above the support frame 202, and the vibrating unit 203 is fixedly connected with the hopper 201, and the horizontal conveyor belt 204 is fixedly installed with side baffles 206 on both sides of the horizontal conveyor belt. 206 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com