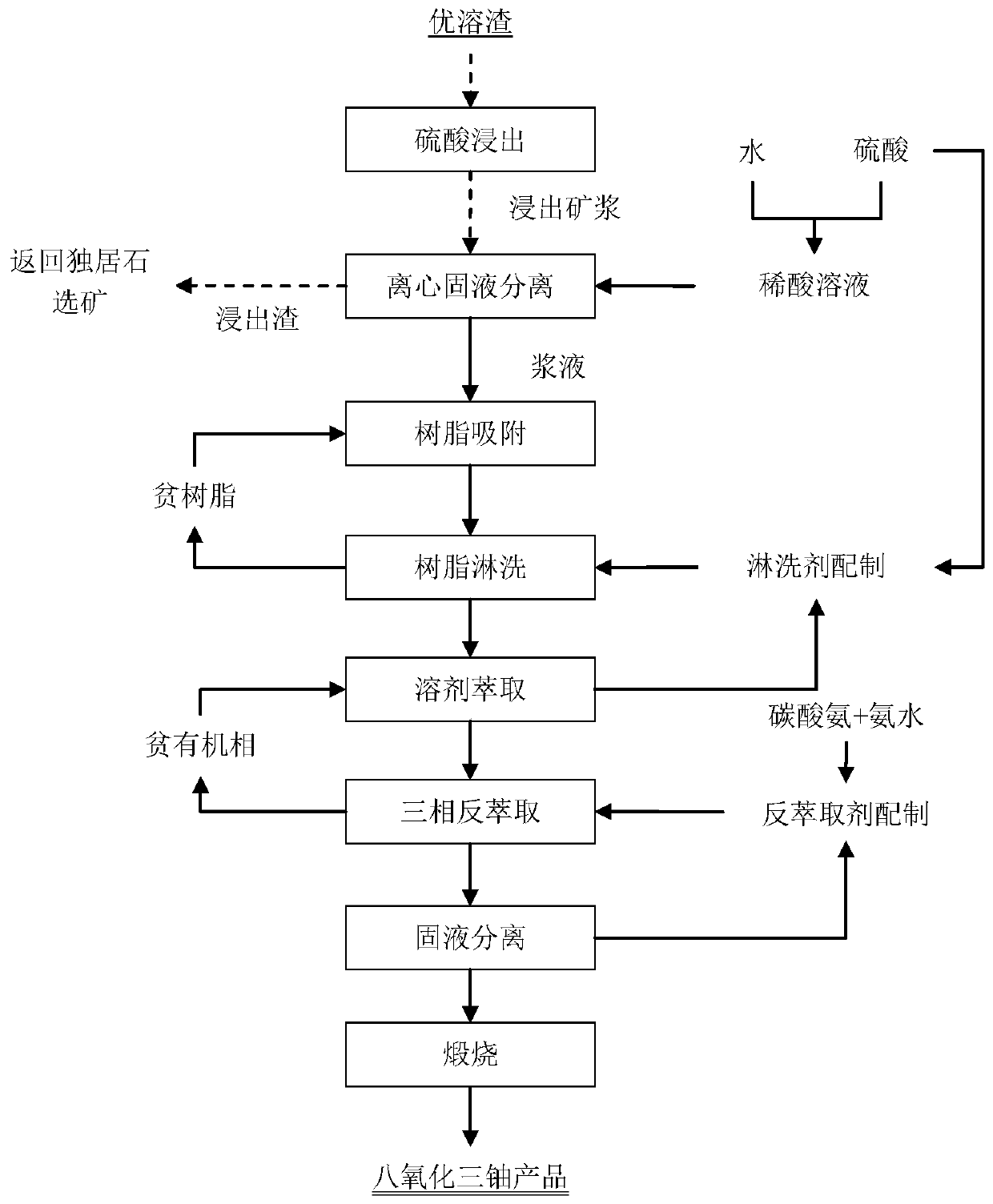

Method for preparing triuranium octoxide from selective solution slag

A technology of U3O8 and melting slag, which is applied in the field of preparation of U3O8, can solve the problems of certain difficulty in the clarity of the extraction liquid and difficult filtration, and achieve simplified extraction liquid system, complete separation of uranium and thorium, and high product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0071] In the sulfuric acid leaching slurry of an excellent slag, the uranium concentration is 1.05g / L, the thorium concentration is 21.1g / L, and the sulfuric acid concentration is 10.4g / L.

[0072] The leaching slurry is centrifuged by a decanter centrifuge with a rotating speed of 3000r / min and a residence time of 0.8min. The solid content of the leaching pulp is 4.1%. D231 resin was used to adsorb the leached pulp, and the uranium content on the obtained loaded resin was 45 mg / g dry resin, and the thorium content was 82 mg / g dry resin. Subsequently, 100g / L sulfuric acid solution was used to rinse the loaded resin, and the concentration of uranium in the qualified solution was 6.1g / L, and the concentration of thorium was 11.1g / L.

[0073] The eluting qualified liquid was extracted with 5% P204+2%TRPO+2%TBP+kerosene for 5-stage countercurrent extraction, the concentration of uranium in the loaded organic phase was 13.5g / L, and the concentration of thorium was 0.006g / L. The l...

example 2

[0075] In the sulfuric acid leaching slurry of an excellent slag, the uranium concentration is 0.51g / L, the thorium concentration is 10.2g / L, and the sulfuric acid concentration is 15.4g / L.

[0076] The leaching slurry is centrifuged by a decanter centrifuge with a rotating speed of 2800r / min and a residence time of 1min. The solid content of the leaching pulp is 2.1%. Using 201*7 resin to adsorb the leached pulp, the uranium content on the obtained loaded resin is 25mg / g dry resin, and the thorium content is 45mg / g dry resin. Then, 110g / L sulfuric acid solution was used to rinse the loaded resin, and the uranium concentration in the leaching qualified liquid was 3.3g / L, and the thorium concentration was 5.9g / L.

[0077] The eluting qualified solution was extracted with 2.5%P204+1.2%TRPO+2%TBP+kerosene for 6-stage countercurrent extraction, the concentration of uranium in the loaded organic phase was 8.5g / L, and the concentration of thorium was 0.008g / L. The load organic phas...

example 3

[0079] In the sulfuric acid leaching slurry of an excellent slag, the uranium concentration is 1.5g / L, the thorium concentration is 32g / L, and the sulfuric acid concentration is 20.4g / L.

[0080] The leaching slurry is centrifuged by a decanter centrifuge with a rotating speed of 3200r / min and a residence time of 0.9min. The solid content of the leaching pulp is 5.2%. D231 resin was used to adsorb the leached pulp, and the uranium content on the obtained loaded resin was 61 mg / g dry resin, and the thorium content was 98 mg / g dry resin. Subsequently, 120g / L sulfuric acid solution was used to rinse the loaded resin, and the uranium concentration in the leaching qualified solution was 8.2g / L, and the thorium concentration was 13.2g / L.

[0081] The eluting qualified solution was extracted with 7% P204 + 4% TRPO + 3% TBP + kerosene for four-stage countercurrent extraction, and the concentration of uranium in the loaded organic phase was 22.1g / L, and the concentration of thorium was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com