Roman cloth and manufacturing method thereof

A production method and polyester technology, applied in the field of fabric production, can solve the problems of poor heat resistance and light resistance, reduce the quality of Roman cloth, poor moisture absorption of Roman cloth, etc., achieve the advantages of not easy to fade, good color fixing effect, and improve wearing comfort Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

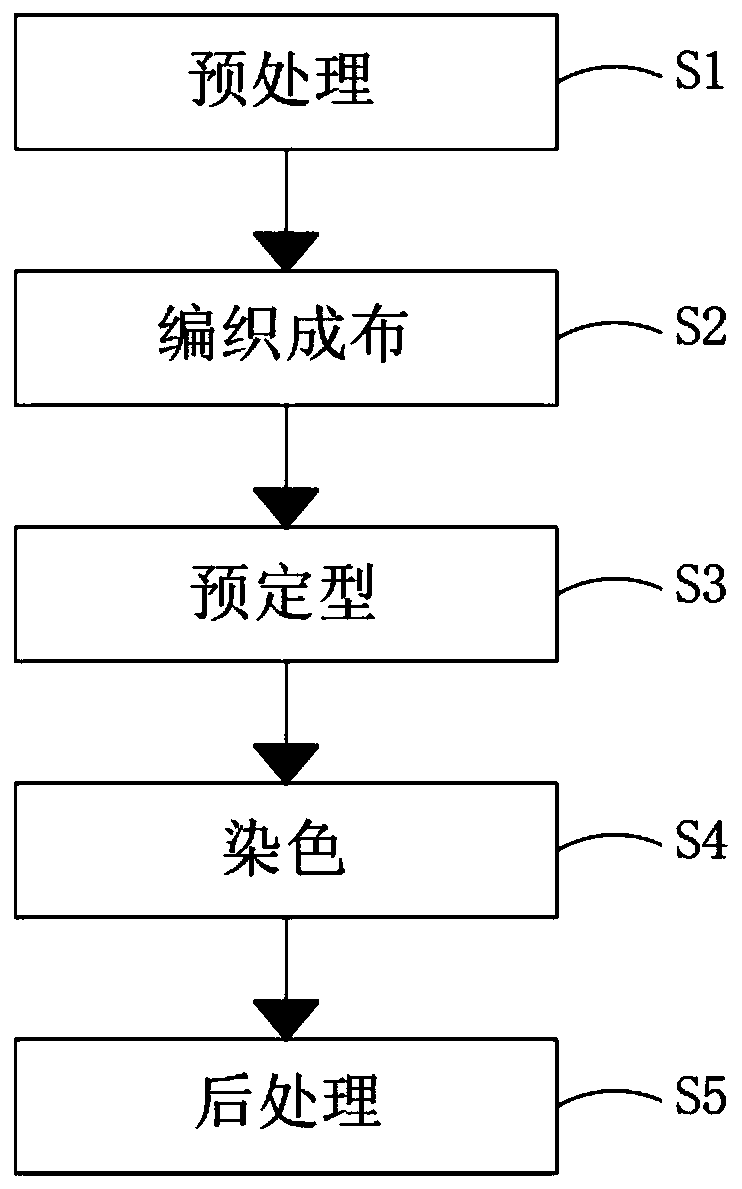

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a Roman cloth, which is made of cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber, and cotton yarn, polyester, spandex, flame-retardant yarn , tc blended yarn and natural bamboo fiber by weight: 25% cotton yarn, 30% polyester, 15% spandex, 10% flame retardant yarn, 10% tc blended yarn, 10% natural bamboo fiber, of which Roman Book Weight is 250-320g / m 2 , the door width is 145-185cm.

[0028] A method for making Roman cloth, comprising the following steps:

[0029] S1. Pretreatment: Soak cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber in warm water, then take it out and put it into the pretreatment pool, add softener to the pretreatment pool and continue soaking for a while Time, then take out the material and cool it under natural conditions. After cooling, use cold water to clean the material. Afte...

Embodiment 2

[0035] The embodiment of the present invention provides a Roman cloth, which is made of cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber interwoven, cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn The percentage by weight of spinning and natural bamboo fiber is: 30% cotton yarn, 35% polyester, 10% spandex, 10% flame-retardant yarn, 10% tc blended yarn, 5% natural bamboo fiber, of which Roman book weight is 250 -320g / m 2 , the door width is 145-185cm.

[0036] A method for making Roman cloth, comprising the following steps:

[0037] S1. Pretreatment: Soak cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber in warm water, then take it out and put it into the pretreatment pool, add softener to the pretreatment pool and continue soaking for a while Time, then take out the material and cool it under natural conditions. After cooling, use cold water to clean the materi...

Embodiment 3

[0043] The embodiment of the present invention provides a Roman cloth, which is made of cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber interwoven, cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn The percentage by weight of spinning and natural bamboo fiber is: 25% cotton yarn, 40% polyester, 10% spandex, 10% flame-retardant yarn, 10% tc blended yarn, 5% natural bamboo fiber, of which Roman book weight is 250 -320g / m 2 , the door width is 145-185cm.

[0044] A method for making Roman cloth, comprising the following steps:

[0045] S1. Pretreatment: Soak cotton yarn, polyester, spandex, flame-retardant yarn, tc blended yarn and natural bamboo fiber in warm water, then take it out and put it into the pretreatment pool, add softener to the pretreatment pool and continue soaking for a while Time, then take out the material and cool it under natural conditions. After cooling, use cold water to clean the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com