A thermal bonding method dust-free puffed paper and its preparation method and application

A technology of puffed paper and thermal bonding, which is applied in textiles and papermaking, spray/jet textile material treatment, removal of liquid/gas/steam, etc., can solve the problems of changing the water absorption performance of the water-absorbing puffed paper layer, and achieve excellent water absorption performance, The effect of guaranteeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

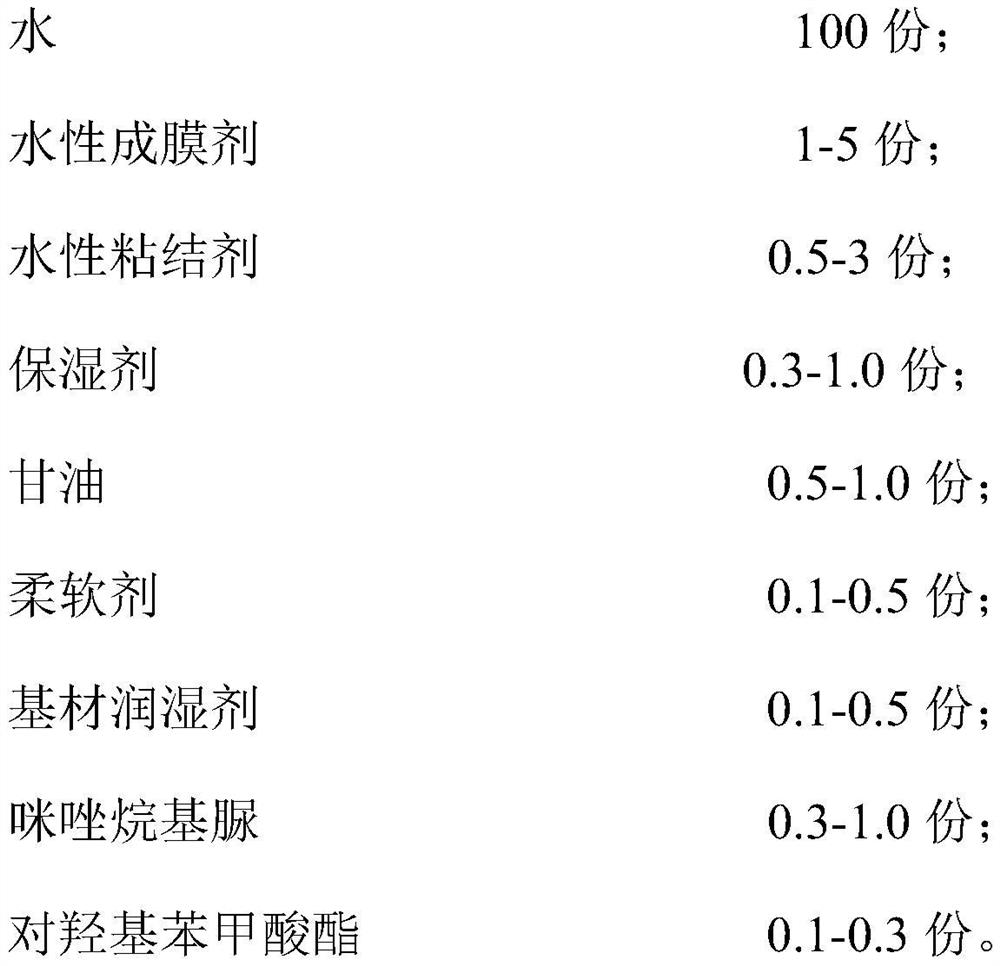

[0058] The dust-free puffed paper surface modifier in embodiment 1 comprises the following components (as shown in table 1) in parts by mass:

[0059] Table 1

[0060]

[0061] After metering the above components, add them into a heated container for stirring and mixing, then raise the temperature to 40°C, stir, dissolve and mix for 1 hour; cool down to room temperature to become a dust-free puffed paper surface modifier.

[0062] The grammage of the expanded paper used in embodiment 1 is 40 grams / m 2 . Bulk paper component: concentric chemical fiber is 1.5 denier, and fiber length is 5cm; Wood fluff pulp fiber is 2cm; The ratio of chemical fiber and wood fluff pulp fiber is 30 / 70.

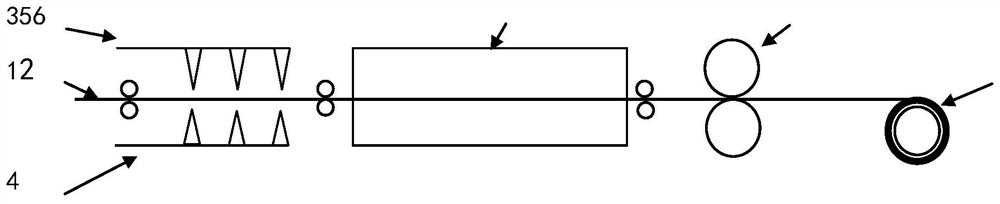

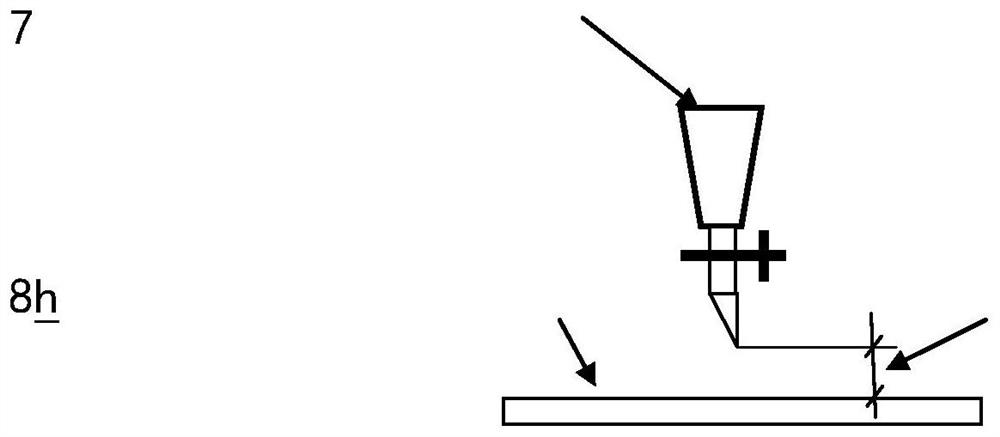

[0063] The puffed paper 1 after air-laid forming enters figure 1 The finished product of the present invention can be obtained after the shown device is sprayed, dried and embossed. figure 1 It is a diagram of the device for preparing thermally bonded dust-free puffed paper according to the...

Embodiment 2

[0070]The dust-free puffed paper surface modifier in embodiment 2 comprises the following components (as shown in table 3) in parts by mass:

[0071] table 3

[0072]

[0073]

[0074] After metering the above components, add them into a heated container for stirring and mixing, then raise the temperature to 60°C, stir, dissolve and mix for 2 hours; cool down to room temperature to become a dust-free puffed paper surface modifier.

[0075] The grammage of the expanded paper used in embodiment 2 is 60 grams / m 2 . Bulk paper component: concentric chemical fiber is 1.5 denier, and fiber length is 5cm; Wood fluff pulp fiber is 2cm; The ratio of chemical fiber and wood fluff pulp fiber is 30 / 70.

[0076] The above expanded paper enters figure 1 The device is sprayed, dried and embossed to obtain the finished product of the present invention.

[0077] When spraying, the modifier is diluted 8 times with industrial pure water, and the temperature of the embossing roller is 1...

Embodiment 3

[0083] The dust-free puffed paper surface modifier in embodiment 3 comprises the following components (as shown in Table 5) in parts by mass:

[0084] table 5

[0085]

[0086] After metering the above components, add them into a heated container for stirring and mixing, then raise the temperature to 50°C, stir, dissolve and mix for 1 hour; cool down to room temperature to become a dust-free puffed paper surface modifier.

[0087] The grammage of the expanded paper used in embodiment 3 is 80 grams / m 2 . Bulk paper component: concentric chemical fiber is 1.5 denier, and fiber length is 5cm; Wood fluff pulp fiber is 2cm; The ratio of chemical fiber and wood fluff pulp fiber is 20 / 80.

[0088] The above expanded paper enters figure 1 The device is sprayed, dried and embossed to obtain the finished product of the present invention.

[0089] When spraying, the modifier is diluted 10 times with industrial pure water, and the temperature of the embossing roller is 120°C; the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com