Battery formation gas detection device and method

A technology for gas detection and battery formation, which is used in volume measurement instruments/methods, measuring devices, liquid/fluid solid measurement, etc. complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

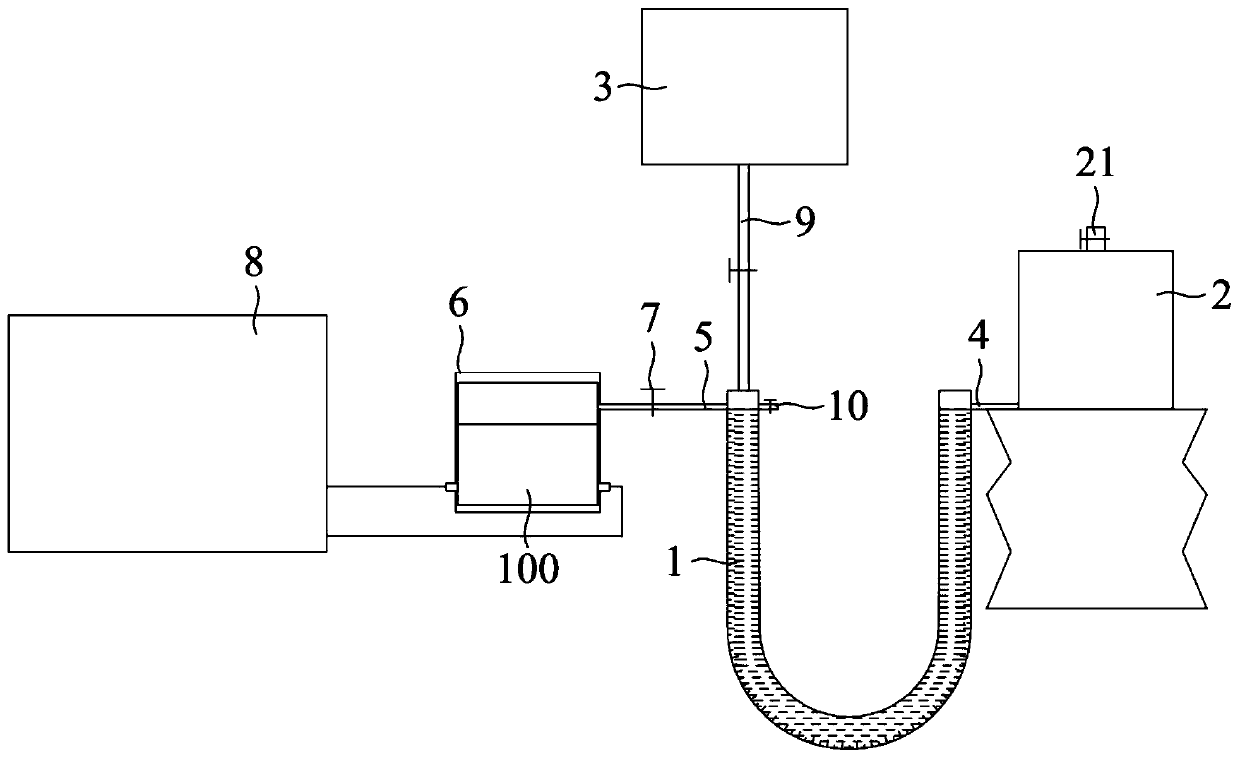

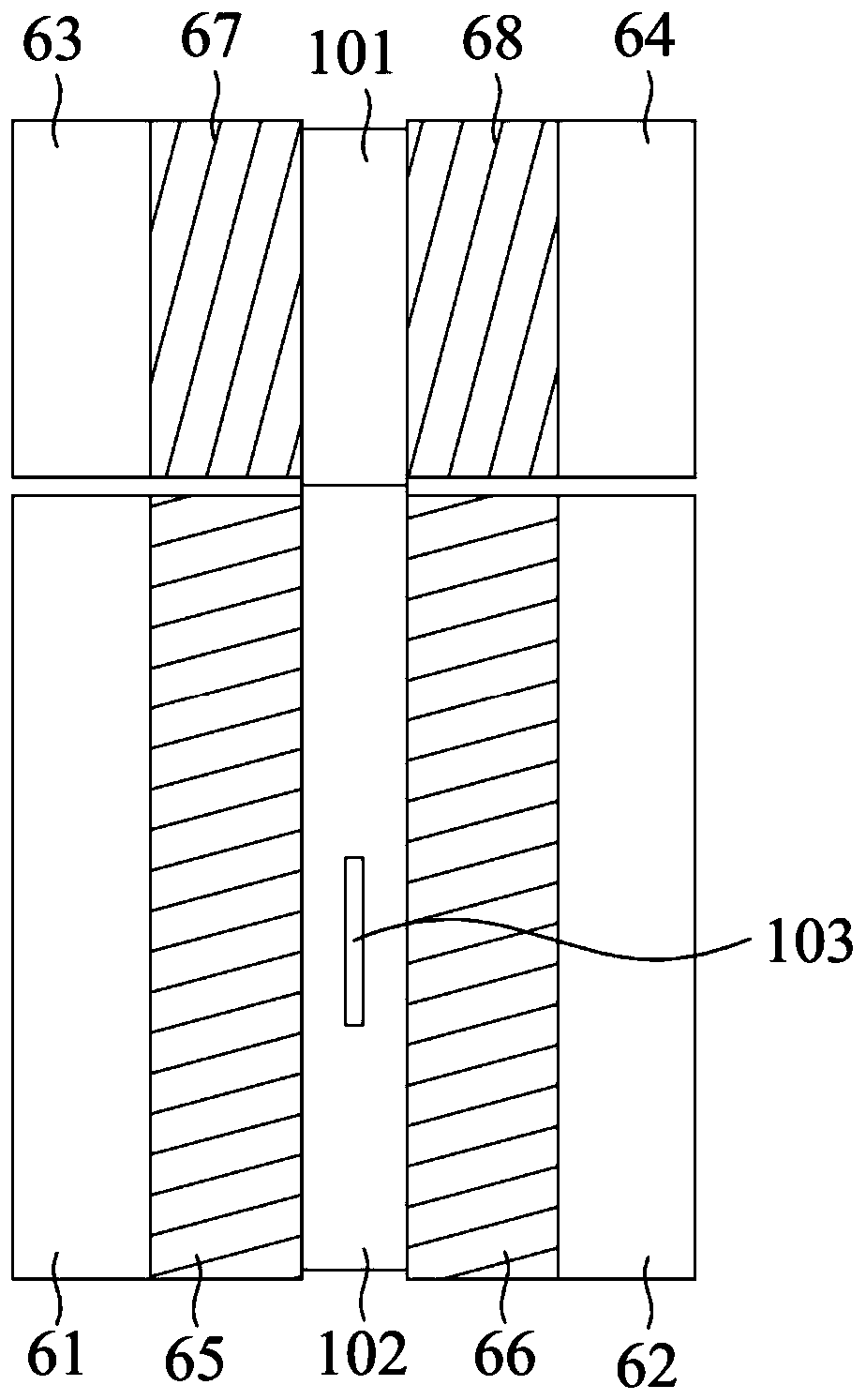

[0050] Such as Figure 1-3 As shown, this embodiment proposes a battery formation gas detection device, and proposes a battery formation gas detection method based on the battery formation gas detection device. Formation gas, and realize the rapid and convenient detection of the volume, composition and content of each composition of the formation gas, so as to provide analysis basis for the optimization and improvement of battery materials and comprehensive performance. Wherein, the battery formation gas detection device mainly includes a transparent elbow 1 , a liquid reservoir 2 and a gas chromatograph mass spectrometer 3 . One end of the transparent elbow 1 is optionally communicated with the gas outlet of the battery 100 to be formed, the other end of the transparent elbow 1 is communicated with the liquid reservoir 2 connected to the atmosphere, and the pipe body between the two ends of the transparent elbow 1 is along the The height in the vertical direction is lower th...

Embodiment 2

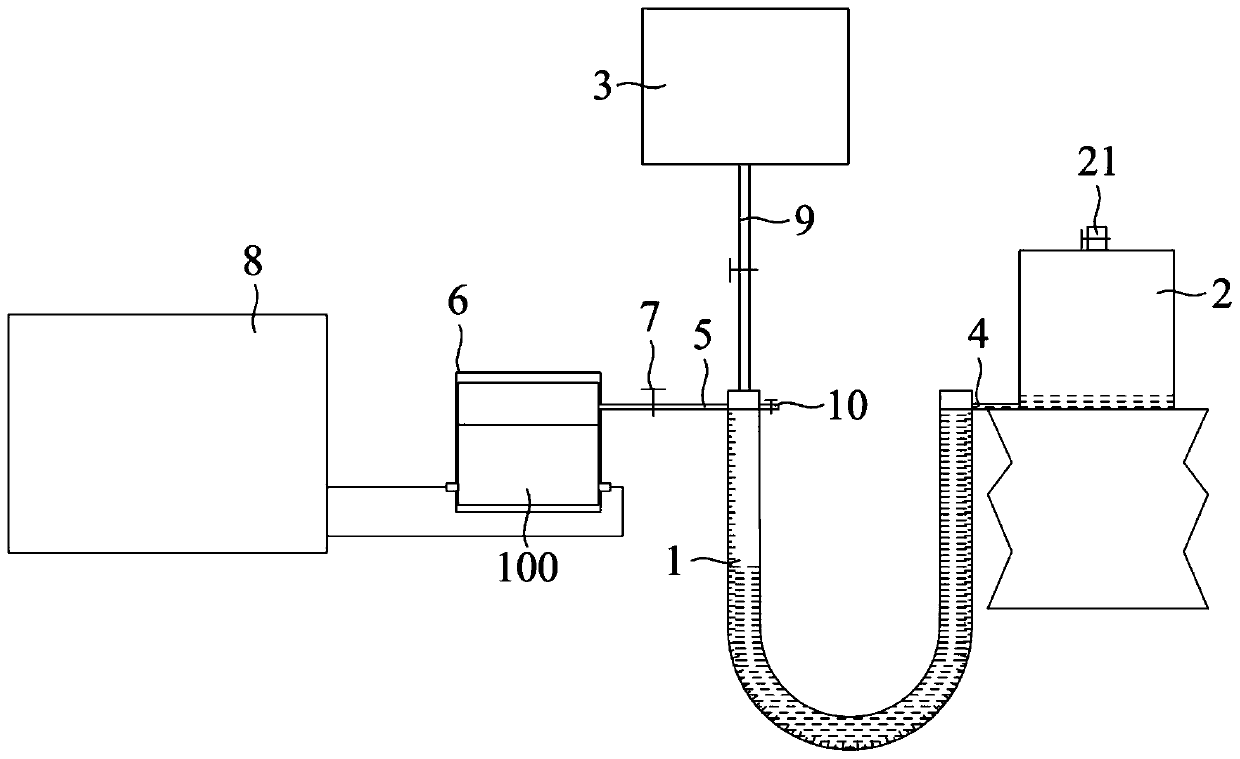

[0068] This embodiment proposes another battery formation gas detection device, and proposes a battery formation gas detection method based on the battery formation gas detection device of this embodiment. Wherein, the structure of the battery formation gas detection device of this embodiment is the same as that of the battery formation gas detection device in Embodiment 1, the only difference is that the battery pressing mechanism 6 of the battery formation gas detection device of this embodiment does not include the third pressing plate 63 and the fourth platen 64 .

[0069] When the battery formation gas detection device of the present embodiment is to be treated with the formation battery 100, the ventilation switch valve 7 is opened, and the switch valve on the analysis communication pipe 9 is closed, and the first pressure plate 61 and the second pressure plate 62 simultaneously control the battery body 102 and the gas bag 101. Apply clamping pressure to press the formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com