A high voltage DC contactor

A high-voltage DC, contactor technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of concentrated bias direction and low degree of deviation of arc direction, to improve the degree of deviation, enhance anti-ablation, Enhance the effect of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

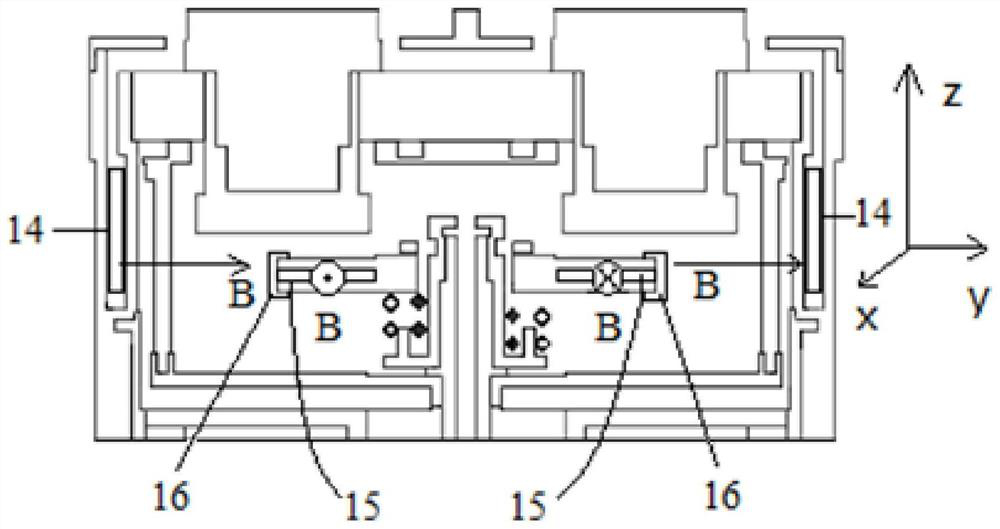

[0033] The nature of the arc is charged particles. When a charged particle is subjected to a magnetic field that is not parallel to the direction of motion, it will be affected by the Lorentz force: Among them, q represents the electric charge of the charged particle, represents the velocity of the charged particle, Indicates the magnetic field (magnetic induction) experienced by charged particles. When the discharge arc is subjected to the Lorentz force, the arc will deviate from the original trajectory. After deviating from the original track, the arc is twisted into a spiral shape, and finally the arc ablation site is no longer concentrated in a certain area on the contact, but tends to be evenly distributed, thereby achieving the effect of improving the electrical life.

[0034] Because electrons are affected by the magnetic field component of the Lorentz force in the direction perpendicular to the direction of motion, they move in a circle. The radius R of circular...

Embodiment 2

[0045] On the basis of the above-mentioned embodiments. The following describes in detail in conjunction with a specific example.

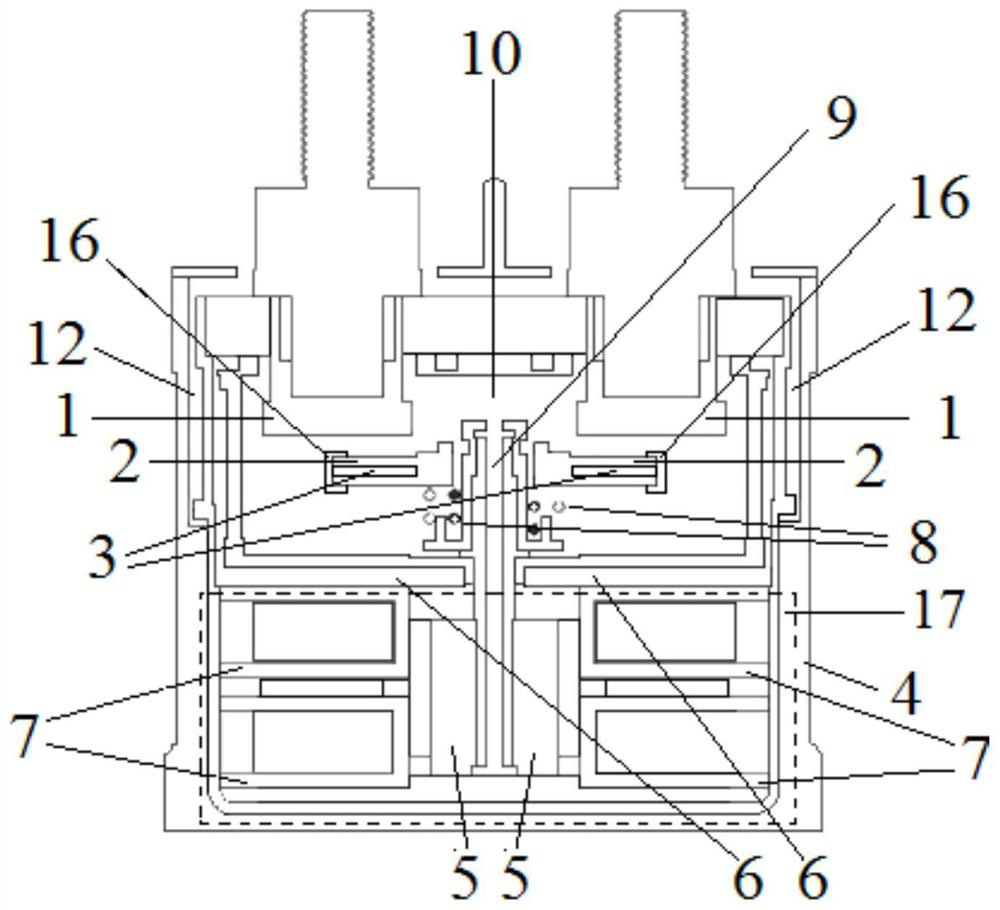

[0046] First, the moving contact magnet 15 is placed in the moving contact magnet groove 3 inside the moving contact 2, and the moving contact magnet sleeve 16 is installed on the outside of the moving contact 2; the static contact The magnetic steel 14 is placed in the static contact magnetic steel groove 12 located on both sides outside the arc extinguishing chamber 10; one end of the magnetic driving rod 9 extending into the arc extinguishing chamber 10 is connected with the magnetic moving contact 2, and the other end passes through After the yoke 6, it is connected with the magnetic drive mechanism 17 through the armature 5. At the same time, the reset coil 7 is placed between the yoke 6 and the armature 5, on both sides of the magnetic drive mechanism 17, and the spring 8 is wound around the magnetic force. on the driving rod 9; so far, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com