Carbon fiber dome, preparation method thereof and loudspeaker

A carbon fiber ball, carbon fiber prepreg technology, applied in the direction of fiber diaphragm, chemical instruments and methods, sensors, etc., can solve the problems of low modulus of carbon fiber ball top, difficult to improve high-frequency performance of products, etc., to improve high-frequency performance, The effect of increasing the modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

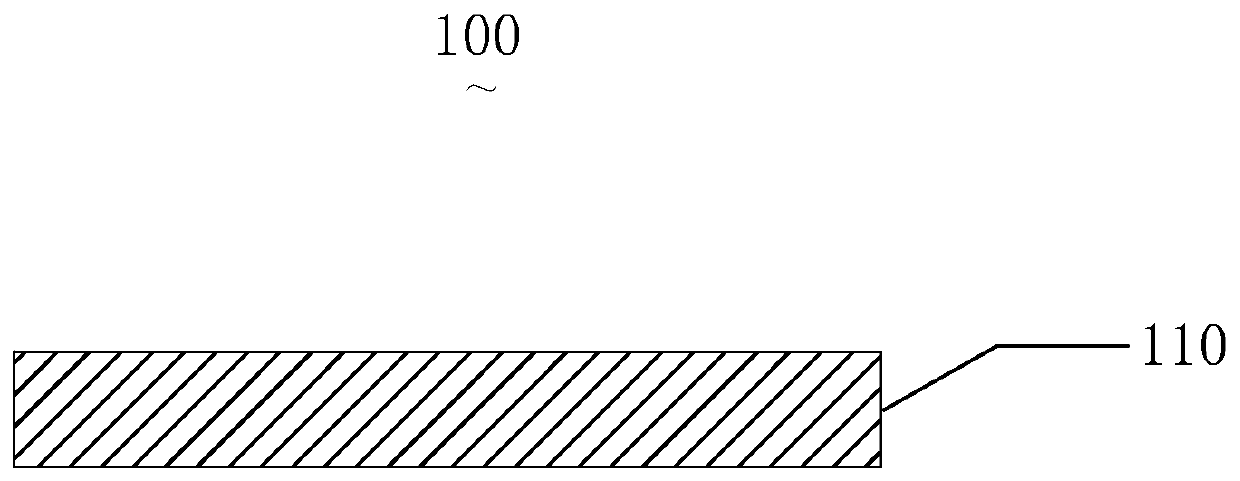

[0029] figure 1 It is a schematic structural view of the carbon fiber dome of Example 1 of the present invention, as figure 1 As shown, the carbon fiber dome 100 includes a carbon fiber layer 110, and the carbon fiber layer 110 includes one or more layers of carbon fiber material prepreg, and the carbon fiber prepreg includes carbon fiber material, resin and reinforcing material dispersed in the resin.

[0030] In this embodiment, in order to improve the flexural modulus of the carbon fiber dome 100, the resin of the carbon fiber prepreg is reinforced, the reinforcing material is in contact with the resin, and the reinforcing material is uniformly dispersed in the resin to form an uncured resin, Then use the resin to pre-impregnate the carbon fiber material to form the carbon fiber material prepreg. carbon fiber impregnated material.

[0031] In this embodiment, the reinforcing material may include one or more of carbon nanotubes, graphene or silica ceramic particles.

[00...

Embodiment 2

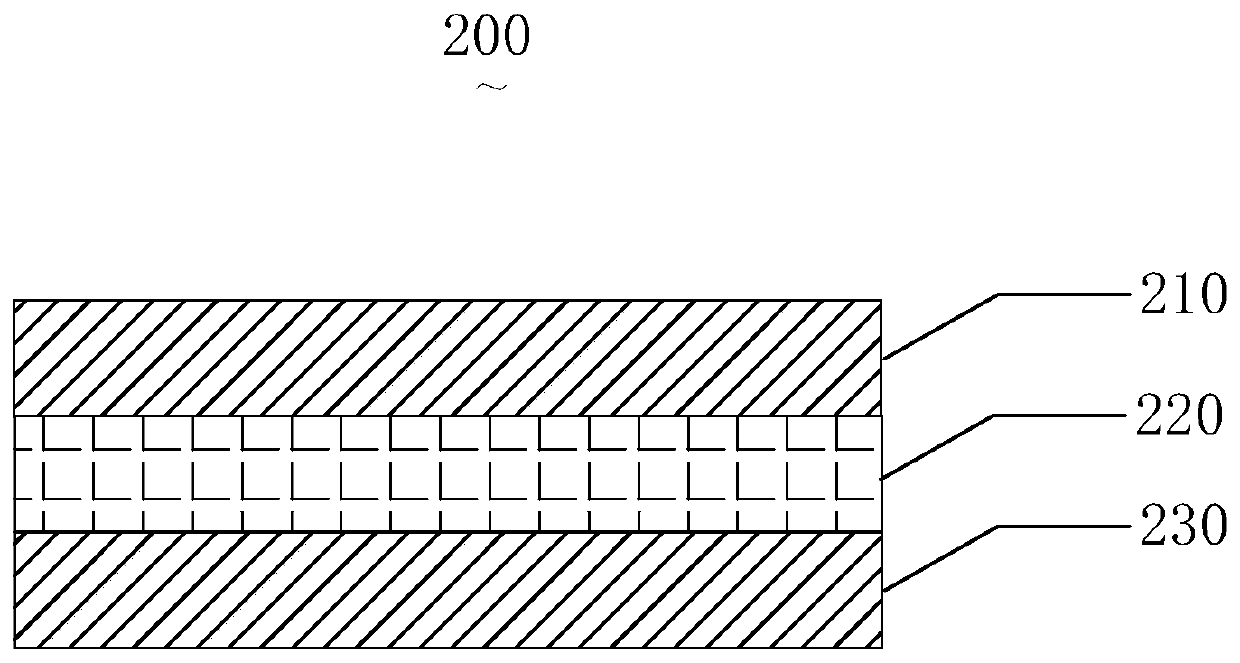

[0046] figure 2 It is a schematic structural view of the carbon fiber dome of Example 2 of the present invention, as figure 2 As shown, the carbon fiber dome 200 includes a first carbon fiber layer 210, a foam material layer 220 and a second carbon fiber layer 230, the first carbon fiber layer 210 and the second carbon fiber layer 230 are respectively arranged on the foam material layer 220 The upper surface and the lower surface, the first carbon fiber layer 210 includes one or more layers of carbon fiber material prepreg, the second carbon fiber layer 230 includes one or more layers of carbon fiber material prepreg, and the carbon fiber prepreg includes carbon fiber material , resin and reinforcing material dispersed in the resin.

[0047] For the description of the first carbon fiber layer 210 and the second carbon fiber layer 230 in this embodiment, please refer to the description of the carbon fiber layer 110 in Embodiment 1, and details are not repeated here.

[0048...

Embodiment 3

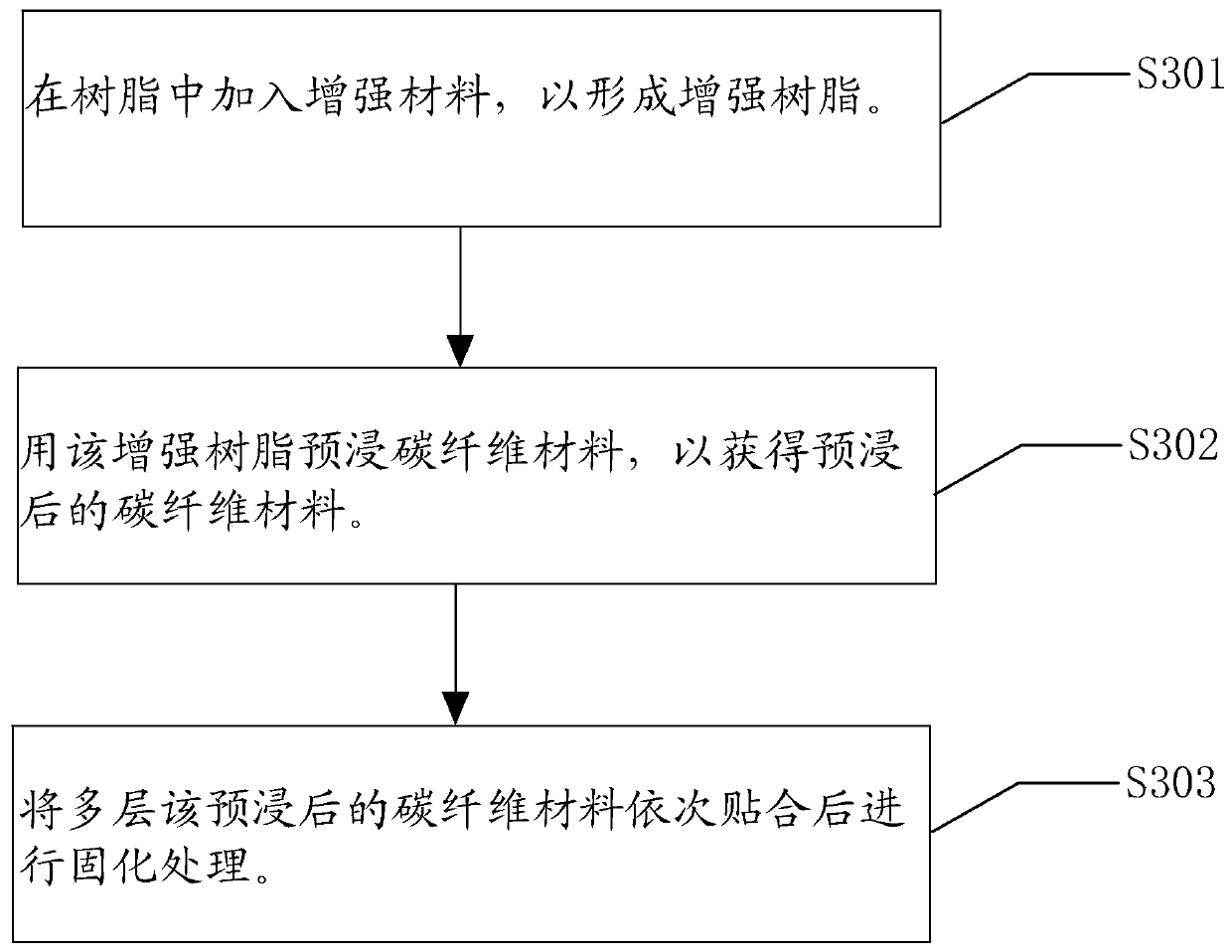

[0051] image 3 It is a flow chart of the preparation method of the carbon fiber dome of Example 3 of the present invention, and the preparation method is used to prepare the carbon fiber dome of Example 1 of the present invention, such as image 3 Shown, this preparation method comprises:

[0052] S301, adding a reinforcing material to the resin to form a reinforced resin.

[0053] S302. Pre-impregnating the carbon fiber material with the reinforcing resin to obtain a pre-impregnated carbon fiber material.

[0054] S303, laminating multiple layers of the pre-impregnated carbon fiber material sequentially and then performing curing treatment.

[0055] The preparation method of the dome structure in the embodiment of the present invention can form a composite layer only by simply sticking it, and then strengthen it through high temperature and high pressure to obtain a dome structure with excellent mechanical properties and acoustic properties, while ensuring aesthetics. In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com