Plant for drying pretreated flexible sheet products

A technology of flexible sheet and drying equipment, applied in the direction of heating to dry solid materials, leather drying, drying solid materials, etc., can solve the problems of increased processing costs, inability to change, limiting compounds and residual moisture in drying efficiency of raw hides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

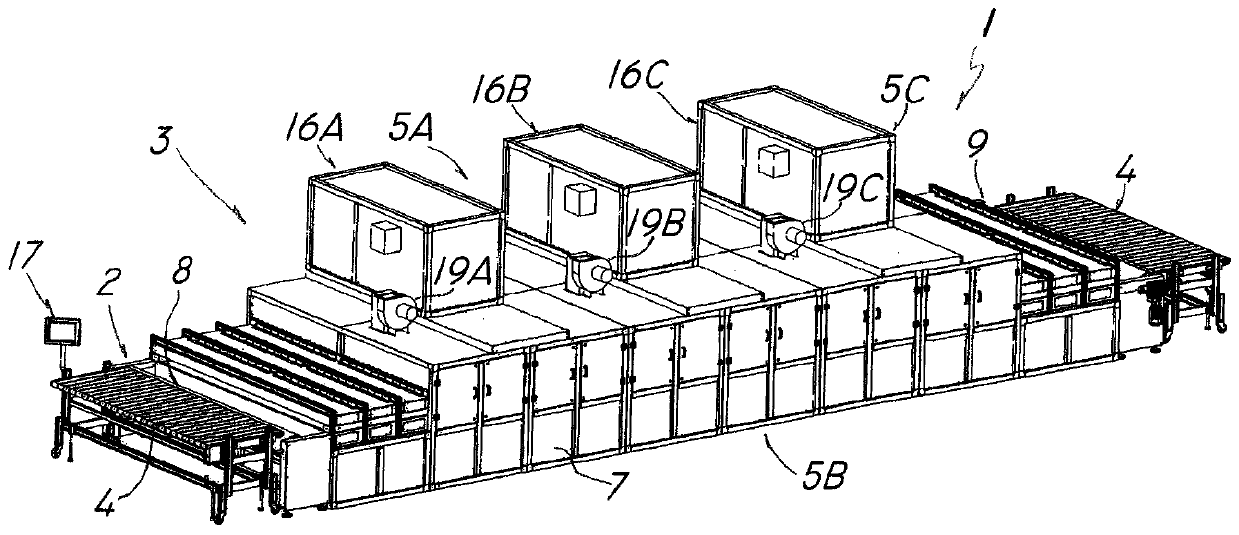

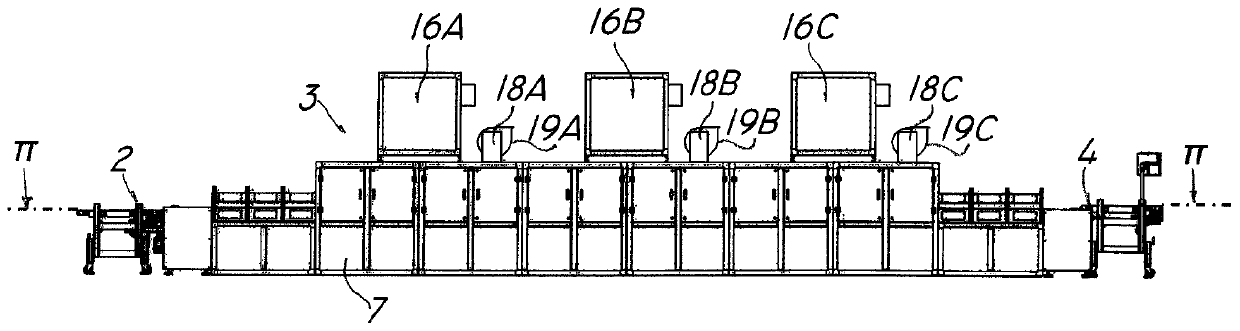

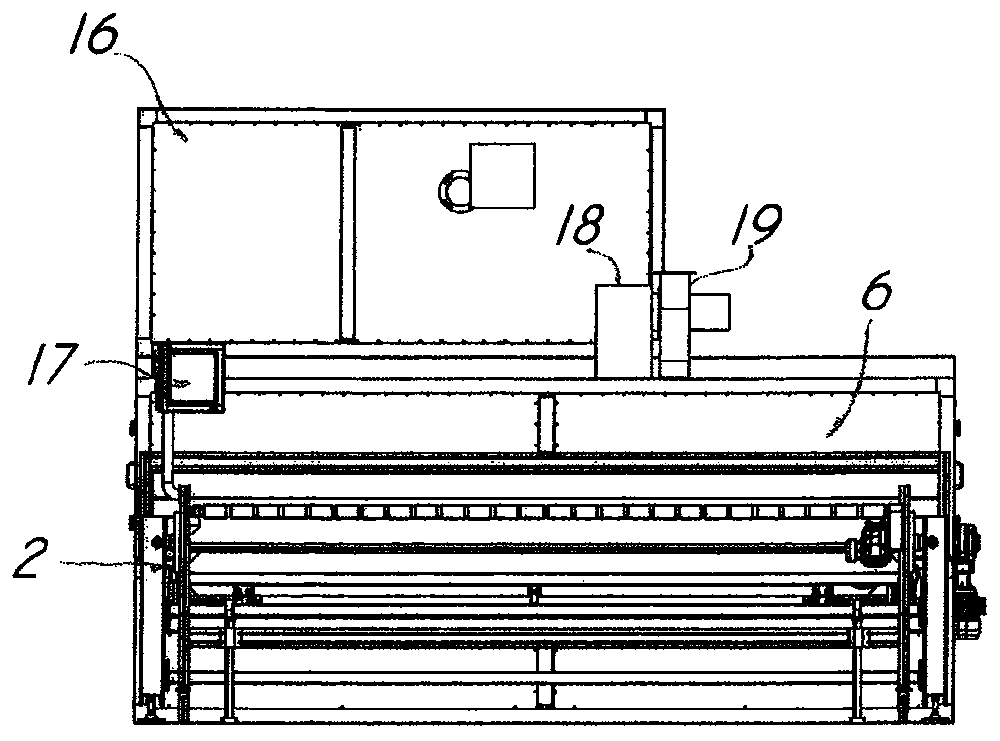

[0042] Referring to the above figures, there is shown an apparatus for drying pretreated flexible sheet products, such as industrial hides, skins, artificial leather or leather derivatives, generally indicated by reference numeral 1 .

[0043] Hides are known to comprise a grain side and a flesh side and to have a pre-deposited layer of finishing compound on one of the two sides, preferably the grain side.

[0044] The compound drying process carried out by the device 1 of the invention imparts specific aesthetic and tactile properties to the leather.

[0045] The finishing compound can be deposited by known deposition methods, such as spraying or roller deposition. The latter is configured to deposit a layer of compound on at least one face of the sheet product with a surface density of 0.001 g / m 2 up to 500g / m 2 , preferably 5g / m 2 up to 150g / m 2 In the range.

[0046] By way of example, the deposited compounds can serve as base coats, color coats and finish coats and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com