Plate rotation type edge sealing band attachment device

A technology of a laminating device and an edge banding strip, which is applied in the field of a plate self-rotating edge banding strip laminating device, can solve the problems of laborious plate movement and the like, and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

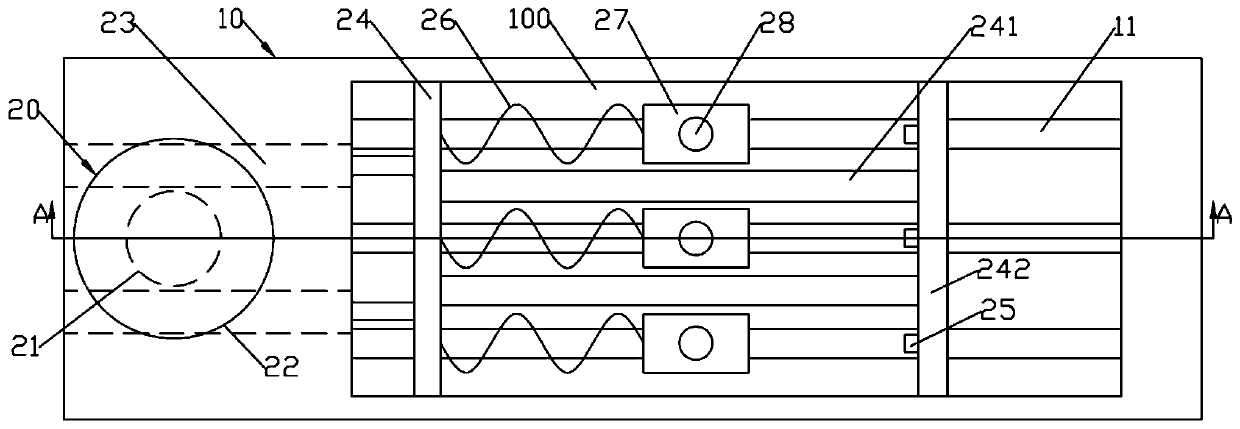

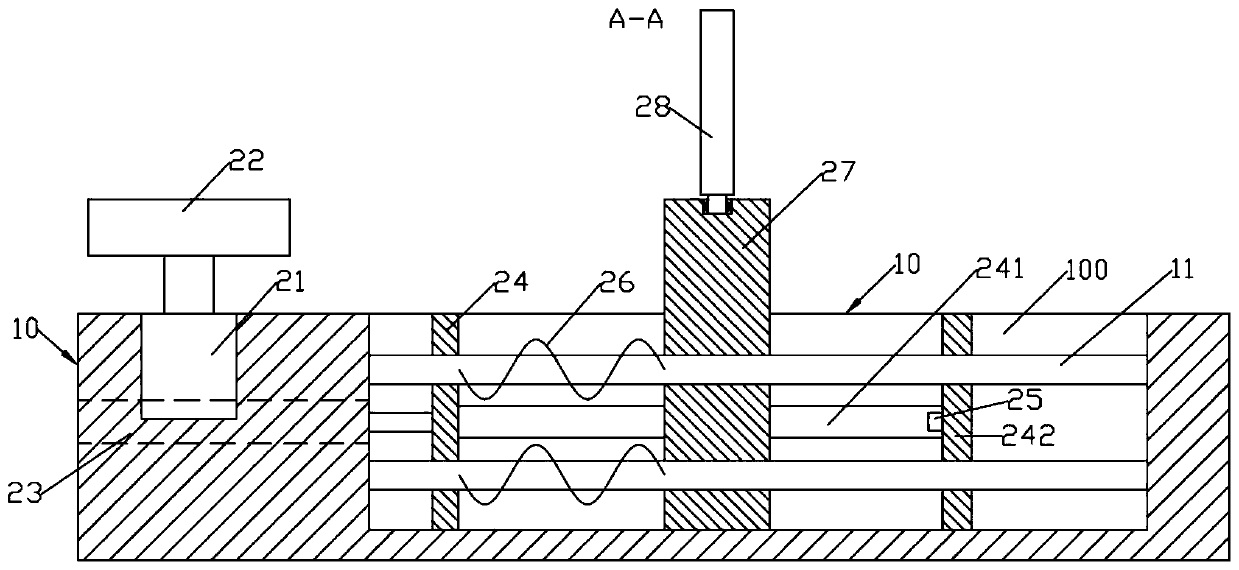

[0015] Such as figure 1 and figure 2 As shown, a sheet metal self-rotating edge banding device includes a cuboid bracket 10 and a self-rotating device 20; the right part of the upper end surface of the bracket 10 is formed with a rectangular fitting slide groove 100; the self-rotating device 20 It includes a supporting plate 22, a sliding limit frame and a number of evenly distributed front and rear left and right sliding support bases 27 arranged in the fitting sliding groove 100; the supporting plate 22 is arranged in the middle of the left end of the upper end surface of the bracket 10 in one-way rotation; the sliding limit frame It includes a left limiting plate 24 that slides left and right and is arranged on the sliding groove 100; several sets of extension spring groups are fixed on the right end surface of the left limiting plate 24; each group of extension spring groups includes a number of extension springs 26 evenly distributed up and down; The right end of extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com