Plane mask ear band welding machine

A welding machine and earband technology, which is applied to household components, household appliances, and other household appliances, can solve problems such as low production efficiency, increased production costs, and increased production costs, so as to improve stability and reliability, improve Ease of operation, improved reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

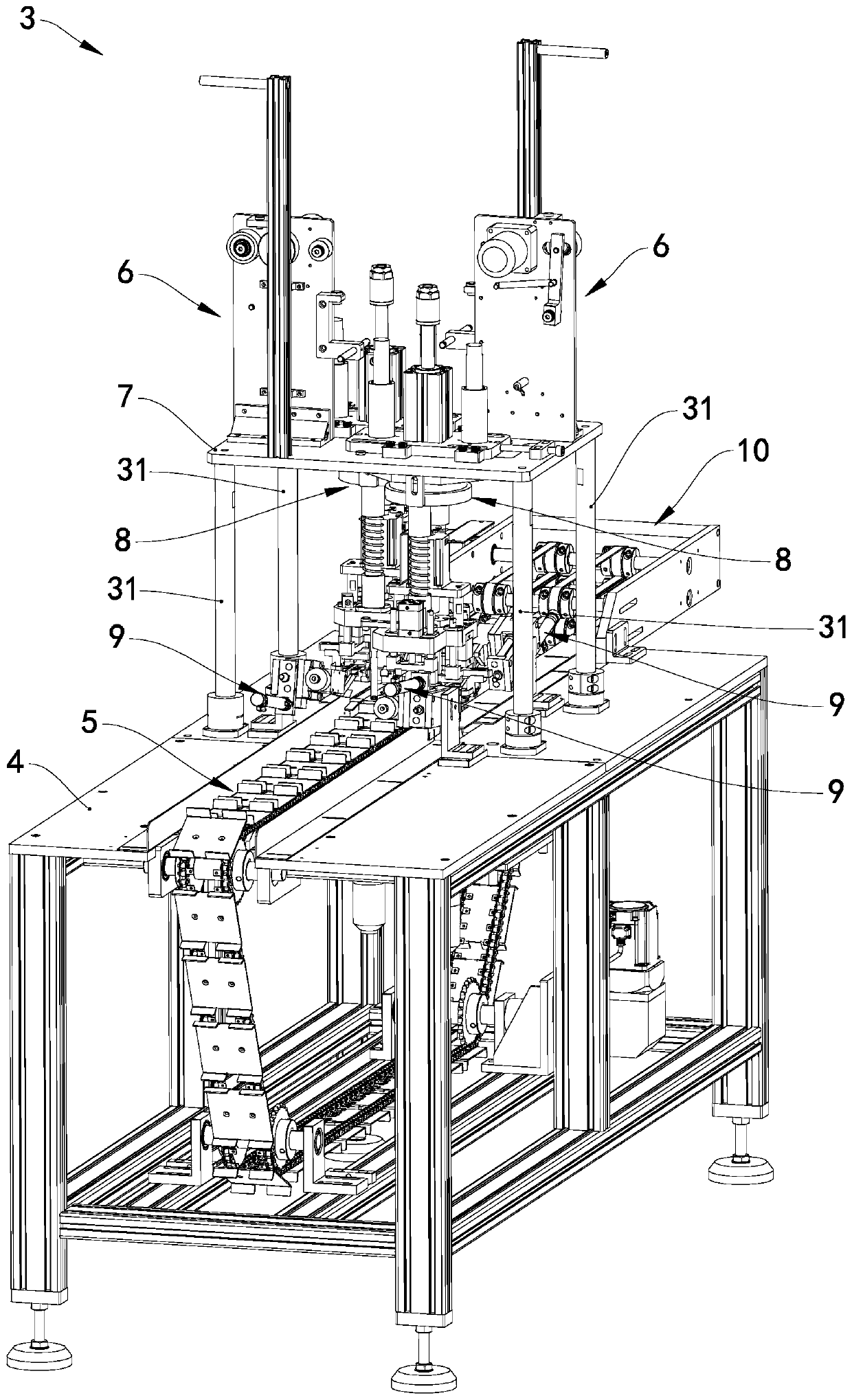

[0051] see image 3 with Figure 4 , the flat face mask earband welding machine 3 includes a frame 4, a conveying device 5, a discharge device 10, an assembly plate 7, two groups of earband welding devices 8, two ultrasonic transducers 20 (see Figure 10 ), two groups of earband feeding devices 6 and four groups of earband cutting devices 9, the conveying device 5 is arranged on the frame 4, and the conveying device 5 includes a driving mechanism, two conveying chains 51 and a plurality of jigs 52, two Conveying chains 51 are arranged side by side parallel to each other, and the driving mechanism controls the two conveying chains 51 to move in the same direction synchronously. A plurality of jigs 52 are respectively located on the two conveying chains 51 and plane masks 1, 2 are placed. The discharge device 10 is positioned at the rear ends of the two conveyor chains 51 in the moving direction of the conveyor chains 51, and the assembly plate 7 is positioned above the conveyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com