Intelligent and efficient sewage treatment equipment for printing and dyeing

A kind of sewage treatment equipment, high-efficiency technology, applied in the direction of water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of cumbersome operation, reduced sewage treatment efficiency, limited service life, etc. To achieve the effect of guaranteeing the treatment effect, improving the treatment efficiency and facilitating the treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

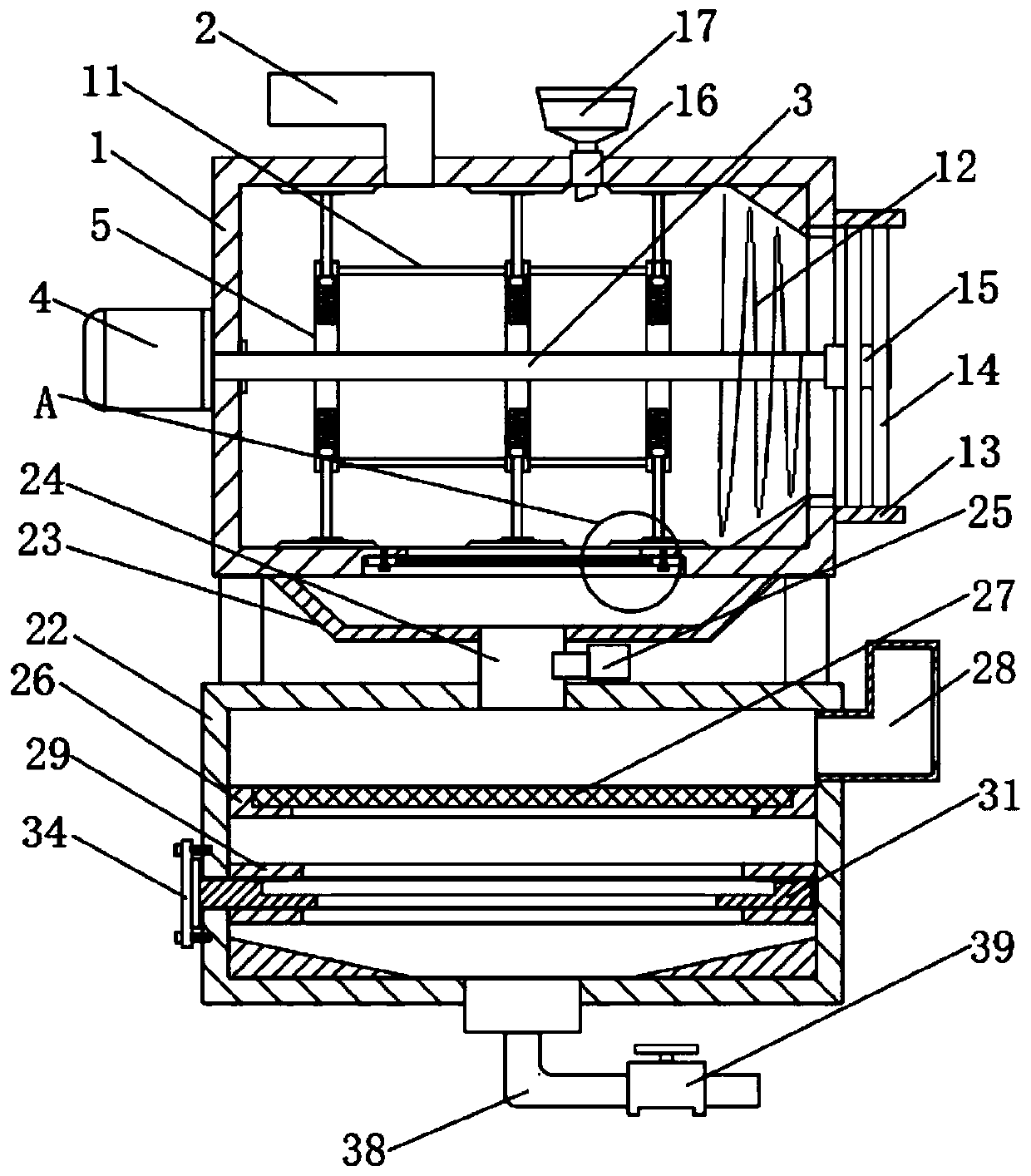

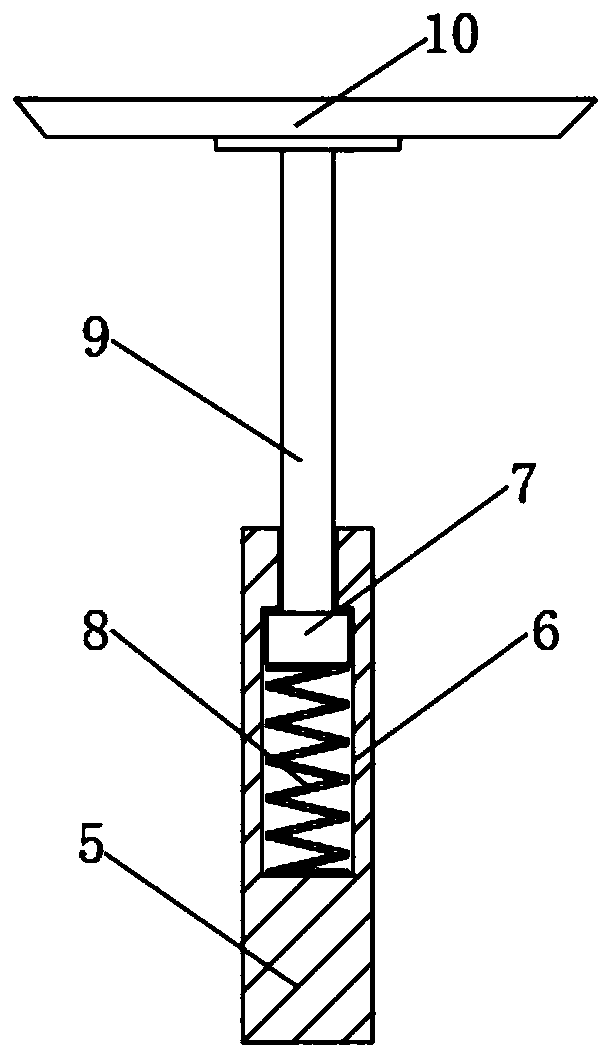

[0027] see Figure 1-5, an intelligent and efficient sewage treatment equipment for printing and dyeing, comprising a first treatment box 1 and a second treatment box 22, the top of the first treatment box 1 is fixedly installed with a sewage input pipe 2, and the middle part of the first treatment box 1 is rotatably connected with a rotating rod 3. A driving motor 4 is fixedly installed on one end of the first processing box 1, and the output end of the driving motor 4 is fixedly connected to one end of the rotating rod 3, and the side wall of the rotating rod 3 is fixedly connected to several stirring parts 5, and the inside of the stirring part 5 A sliding groove 6 is provided, a sliding block 7 is slidably connected in the sliding groove 6, a supporting spring 8 is fixedly installed at the bottom of the sliding block 7, a supporting column 9 is fixedly connected to the top of the sliding block 7, and the other end of the supporting column 9 is fixedly connected with a The ...

Embodiment 2

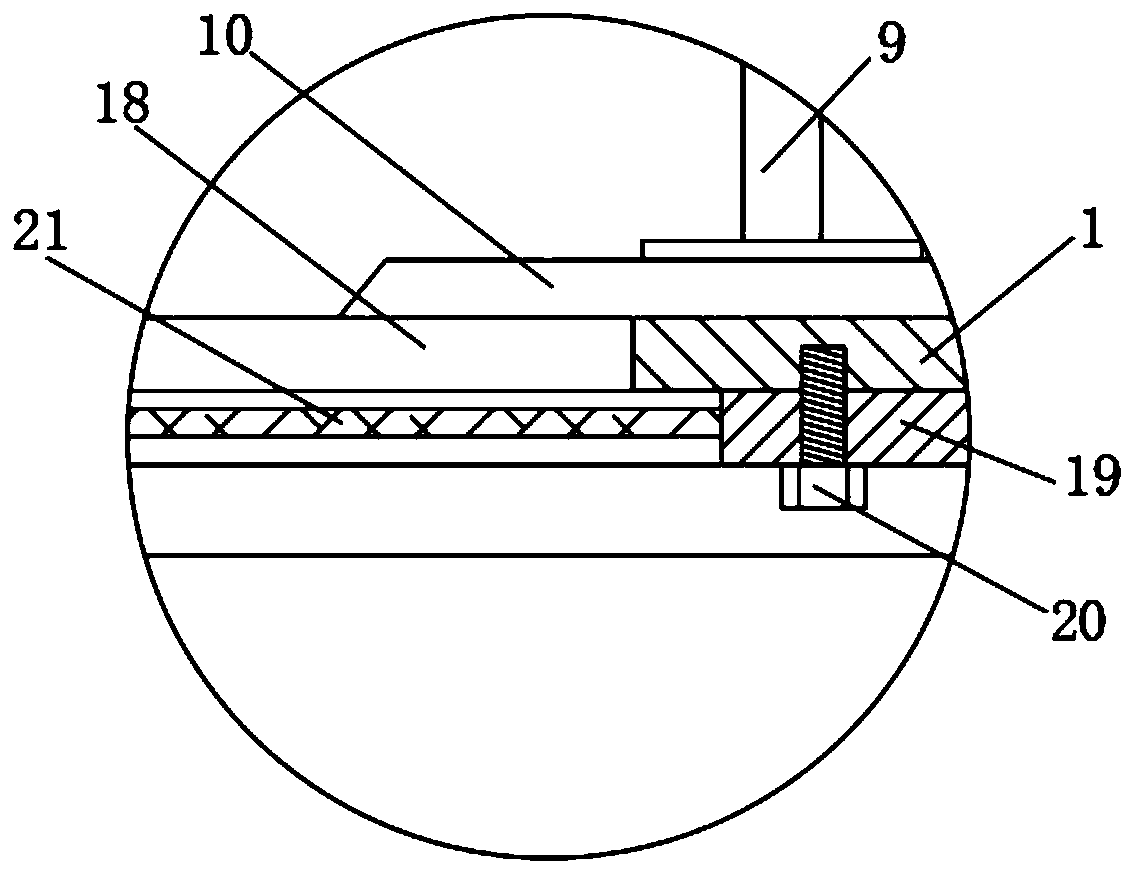

[0030] see Figure 1-5 , made further improvements on the basis of Example 1: a connecting rod 11 is fixedly connected between the two stirring parts 5, and the connecting rod 11 is located on the side away from the rotating rod 3; Rod 14, the middle part of stabilizing rod 14 is fixedly connected with fixed cover 15, and one end of rotating rod 3 is rotatably connected in fixed cover 15; frame 19, the middle part of the first mounting frame 19 is fixedly connected with a first filter screen 21, and both sides of the bottom end of the first mounting frame 19 are fixedly equipped with first screws 20.

[0031] In the present embodiment, it can be ensured that the two stirring members 5 have good stability in the stirring process through the connecting rod 11, the fixing sleeve 15 is fixed by the stabilizing rod 14, and then the fixing sleeve 15 supports the rotating rod 3 to ensure The rotating rod 3 has better stability during the rotating process, and the sewage passes throu...

Embodiment 3

[0033] see Figure 1-5 , On the basis of Embodiment 1, a further improvement has been made: the middle part of the second processing box 22 is fixedly connected with a second mounting frame 26, and the middle part of the second mounting frame 26 is fixedly connected with a second filter screen 27, and the side wall of the second processing box 22 A slag discharge box 28 is fixedly connected, and the bottom height of the slag discharge box 28 is located at the top of the second filter screen 27 .

[0034] In this embodiment, the sewage in the first treatment tank 1 is gradually discharged into the second treatment tank 22 through the discharge pipe 24, and then filtered through the second filter screen 27. After filtering for a period of time, it can pass through the slag discharge box 28. The waste residue is cleaned up, so that the treatment of sewage will not be affected while cleaning up the waste residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com