Prestressed steel strand with strength of 2100 MPa and production process

A prestressed steel strand, 2100mpa technology, applied in the field of smelting, can solve problems such as difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

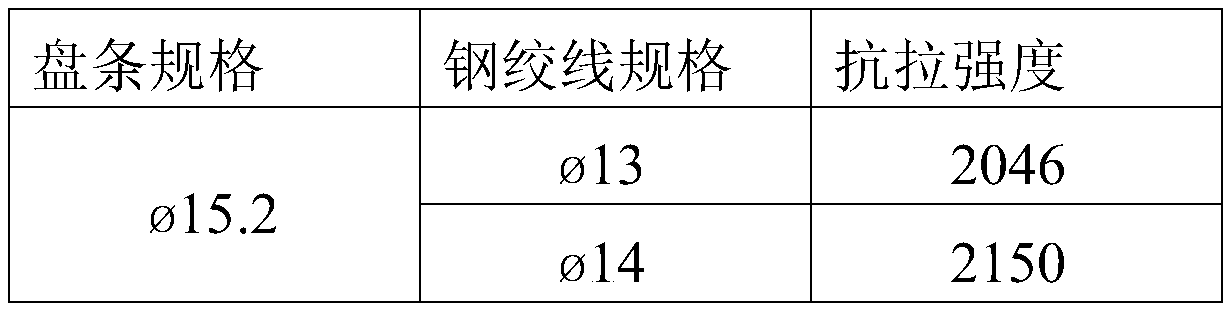

[0037] A prestressed steel strand with a strength of 2100MPa, its chemical composition includes C: 0.86%, Si: 0.30%, Mn: 0.80%, Cr: 0.013%, P: 0.003%, S: 0.15%, Al: 0.032%, V: 0.037%, the rest is Fe and unavoidable impurities, and the diameter of the steel strand is 13 or 14mm.

[0038] The preferred raw material for steel strand production is air-cooled and hot-rolled wire rod with a diameter of Φ14mm and a strength of not less than 1400MPa; the preferred grade of wire rod used is QS92Si-HT, and the C content is 0.9% to 0.95%.

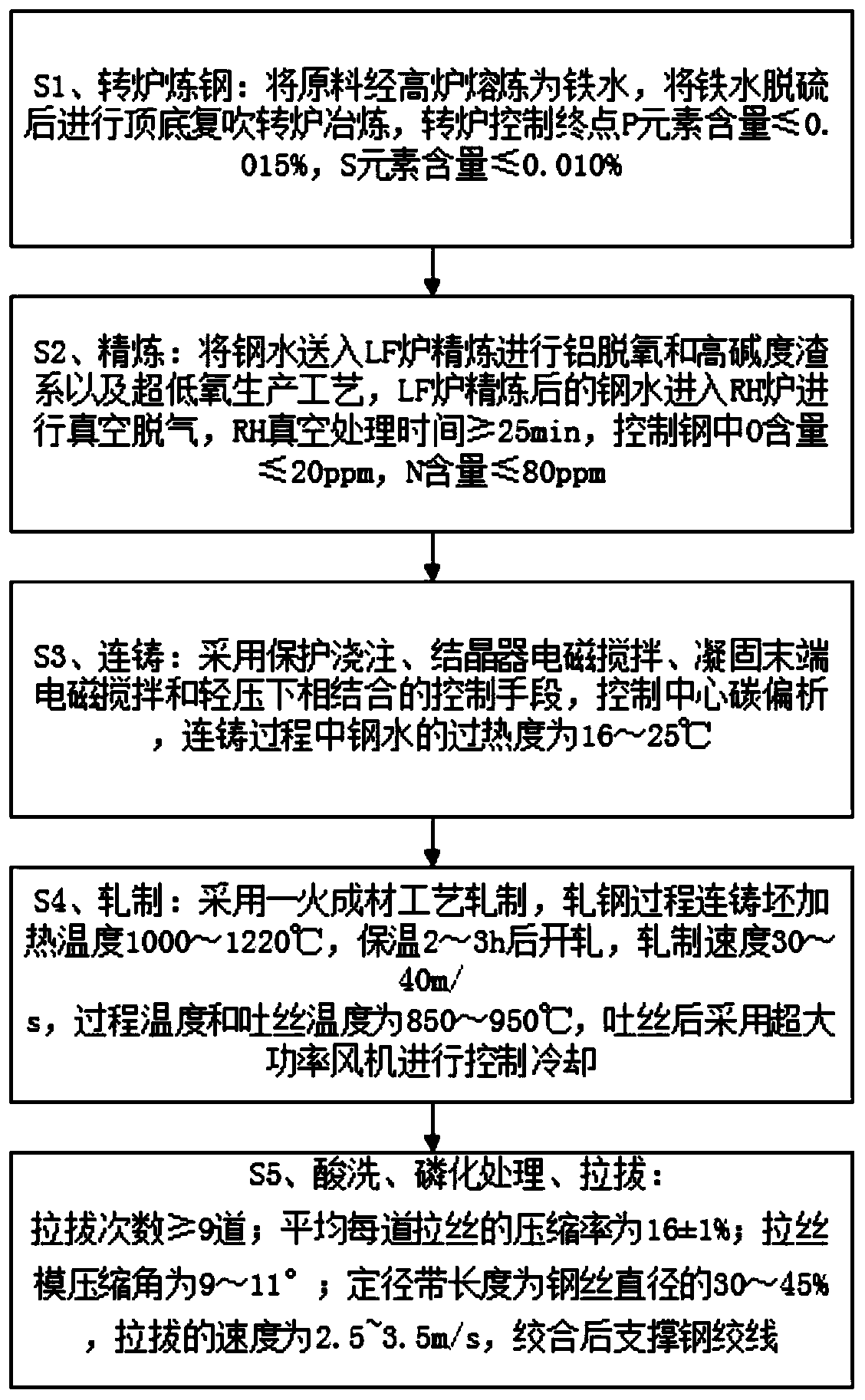

[0039] Such as figure 1 As shown, the production process of 2100MPa grade prestressed steel strand includes the following steps:

[0040] S1. The raw materials are sent to KR or granular magnesium desulfurization through the blast furnace molten iron, and then sent to the top-bottom combined blowing converter for smelting. After desulfurization of blast furnace molten iron, the converter adopts double slag blowing method, which can reduce the conten...

Embodiment 2

[0061] A prestressed steel strand with a strength of 2100MPa, its chemical composition includes C: 0.87%, Si: 0.60%, Mn: 0.65%, Cr: 0.011%, P: 0.002%, S: 0.30%, Al: 0.011%, V: 0.023%, the rest is Fe and unavoidable impurities, and the diameter of the steel strand is 13 or 14mm.

[0062] The preferred raw material for steel strand production is air-cooled and hot-rolled wire rod with a diameter of Φ14 mm and a strength of not less than 1200 MPa; the preferred grade of wire rod used is QS87Mn, and the C content is 0.85%-0.89%.

[0063] Such as figure 1 As shown, the production process of 2100MPa grade prestressed steel strand includes the following steps:

[0064] S1. The raw materials are sent to KR or granular magnesium desulfurization through the blast furnace molten iron, and then sent to the top-bottom combined blowing converter for smelting. After desulfurization of blast furnace molten iron, the converter adopts double slag blowing method, which can reduce the content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com