Asphalt pavement flatness detection device

An asphalt pavement and detection device technology, applied in mechanical roughness/irregularity measurement, roads, roads, etc., can solve problems such as affecting the driver's driving experience, causing traffic accidents, and high maintenance costs, achieving applicability and flexibility. The effect of improving performance and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

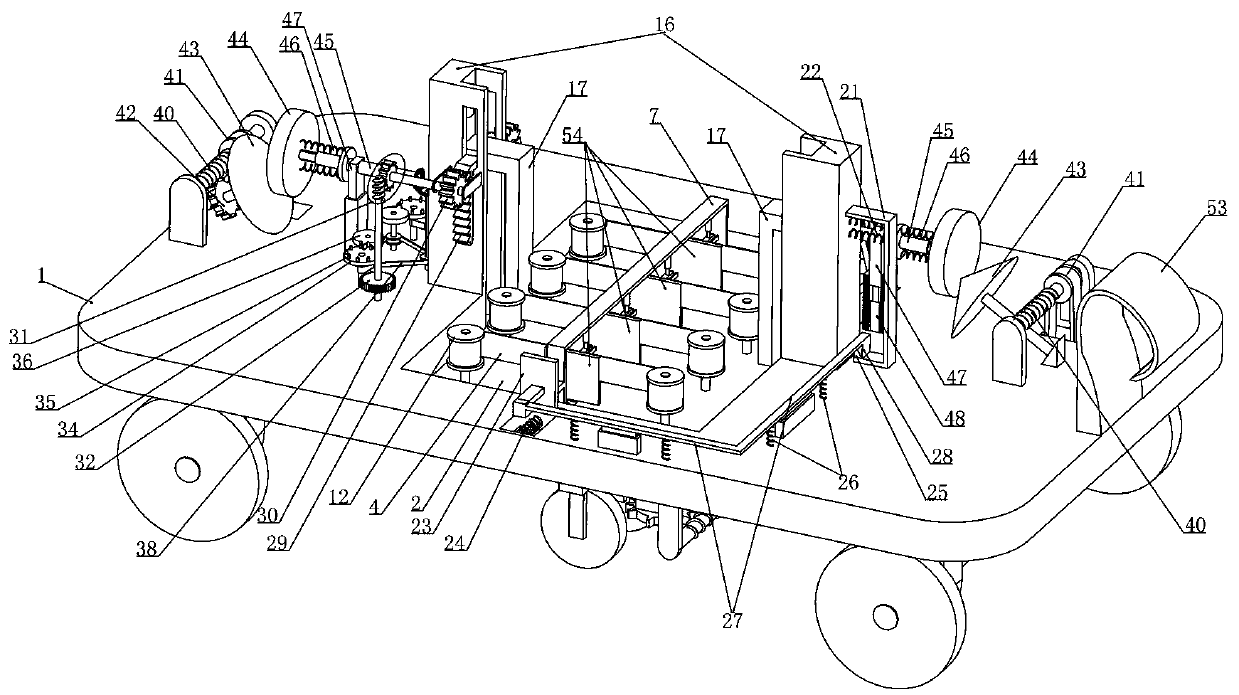

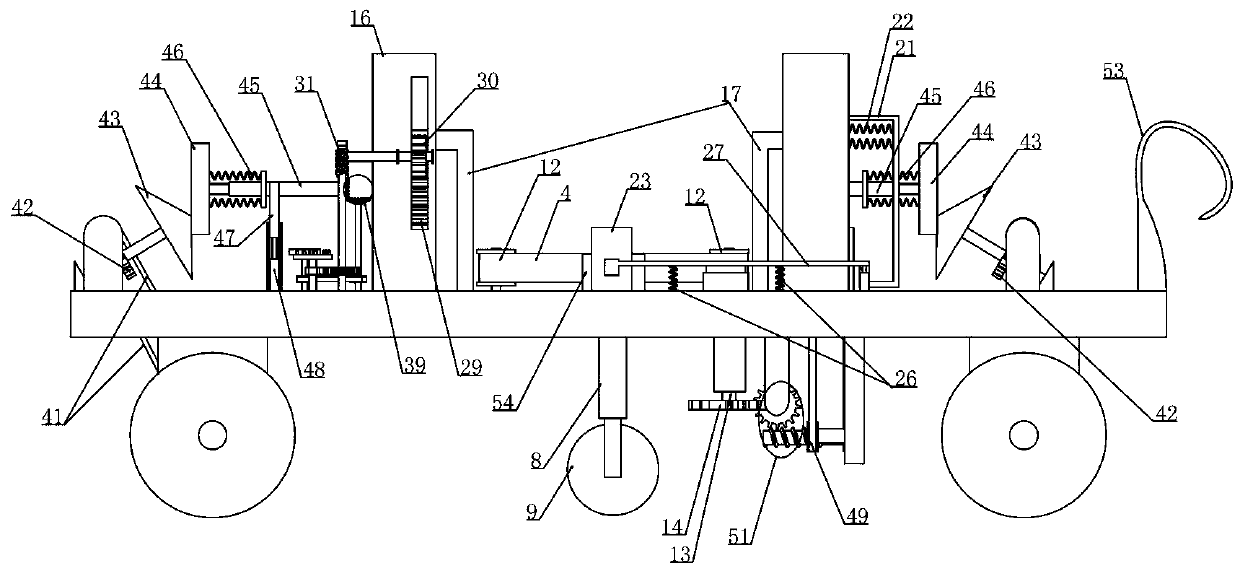

[0040] Embodiment 1, this embodiment provides a kind of asphalt pavement roughness detection device, refer to the attached figure 1 As shown, it includes a dolly 1, the bottom of the dolly 1 is rotated on both sides laterally, and a wheel axle 5 is installed on the wheel axle 5, and a hook 53 is fixed at one end of the dolly 1 in the transverse direction. When the detection device is working, we The detection vehicle drags the trolley 1 through the hook 53 to run at a constant speed along the detection road at a set speed;

[0041] We vertically slide and install a bearing plate 2 on the trolley 1, and a detection unit vertically slidably installed on the bearing plate 2 is arranged at longitudinal intervals on the bearing plate 2, and a compression spring 3 is connected between the detection unit and the bearing plate 2 , when the trolley 1 drives at a constant speed under the drag of the detection vehicle, several detection units keep in close contact with the ground under t...

Embodiment 2

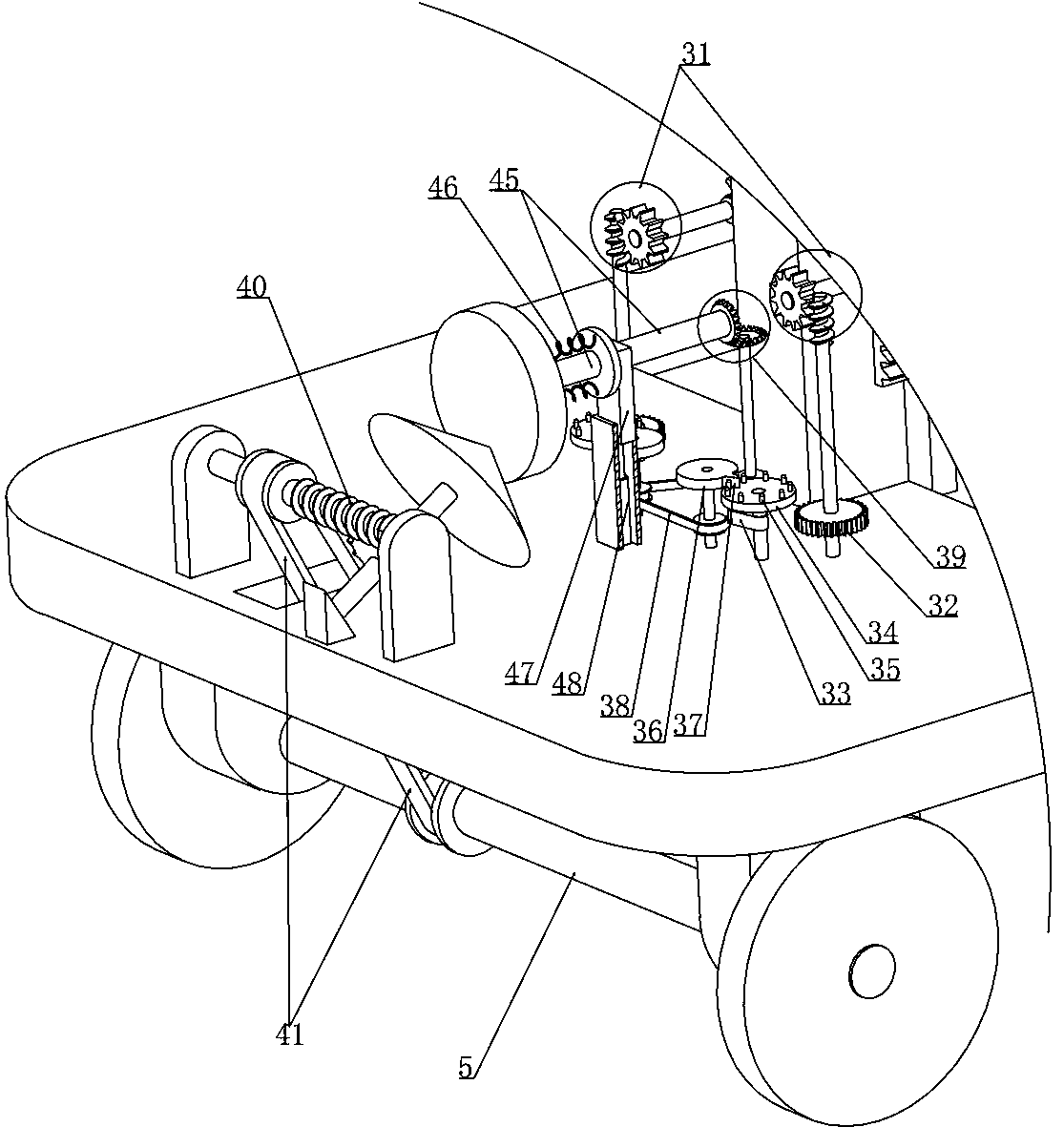

[0050] Embodiment 2, on the basis of embodiment 1, with reference to appended Figure 8 As shown, the detection unit includes a detection frame 8 arranged at intervals in the longitudinal direction and vertically slidably installed on the bearing plate 2, referring to the attached Figure 7 As shown, the compression spring 3 is connected between the bearing plate 2 and the detection frame 8, and under the elastic force of the compression spring 3, the detection wheel 9 is tightly against the road surface. When the trolley 1 is dragged by the detection vehicle When advancing along the detected road, a plurality of detection wheels 9 are synchronously driven to rotate, and when the detection wheels 9 move to the position where there are potholes or protrusions on the road surface, the detection frame 8 is driven by the detection wheels 9 to move vertically along the bearing plate 2. move, see attached Figure 8 As shown, the upper end of the detection frame 8 is vertically slid...

Embodiment 3

[0051] Embodiment 3, on the basis of embodiment 1, with reference to appended Figure 8 As shown, one of the reels 12 in each group of the reels 12 is coaxially rotated and fitted with a transmission cylinder 13 rotatably mounted on the trolley 1, and the axial sliding fit between the transmission cylinder 13 and the shaft of the reel 12 is Therefore, the axial sliding fit between the reel 12 shaft and the transmission cylinder 13 is set to cooperate with the vertical movement of the bearing plate 2, so that the reel 12 shaft and the corresponding transmission cylinder 13 can always realize power transmission ;

[0052] The first transmission device includes a first worm wheel 14 that rotates coaxially with the transmission cylinder 13, and a plurality of the first worm wheels 14 are meshed with a first worm 15 that is rotatably mounted on the trolley 1, and the first worm 15 passes through the first worm wheel 14. Driven by a speed regulating device, the wheels of the trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com