Manual hole digging pile pre-reinforcing retaining wall structure and construction process

A technology of artificial digging piles and construction technology, which is applied in basic structure engineering, sheet pile walls, buildings, etc., can solve problems such as high risk and low work efficiency, increase bearing capacity, improve construction efficiency, and ensure safety and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

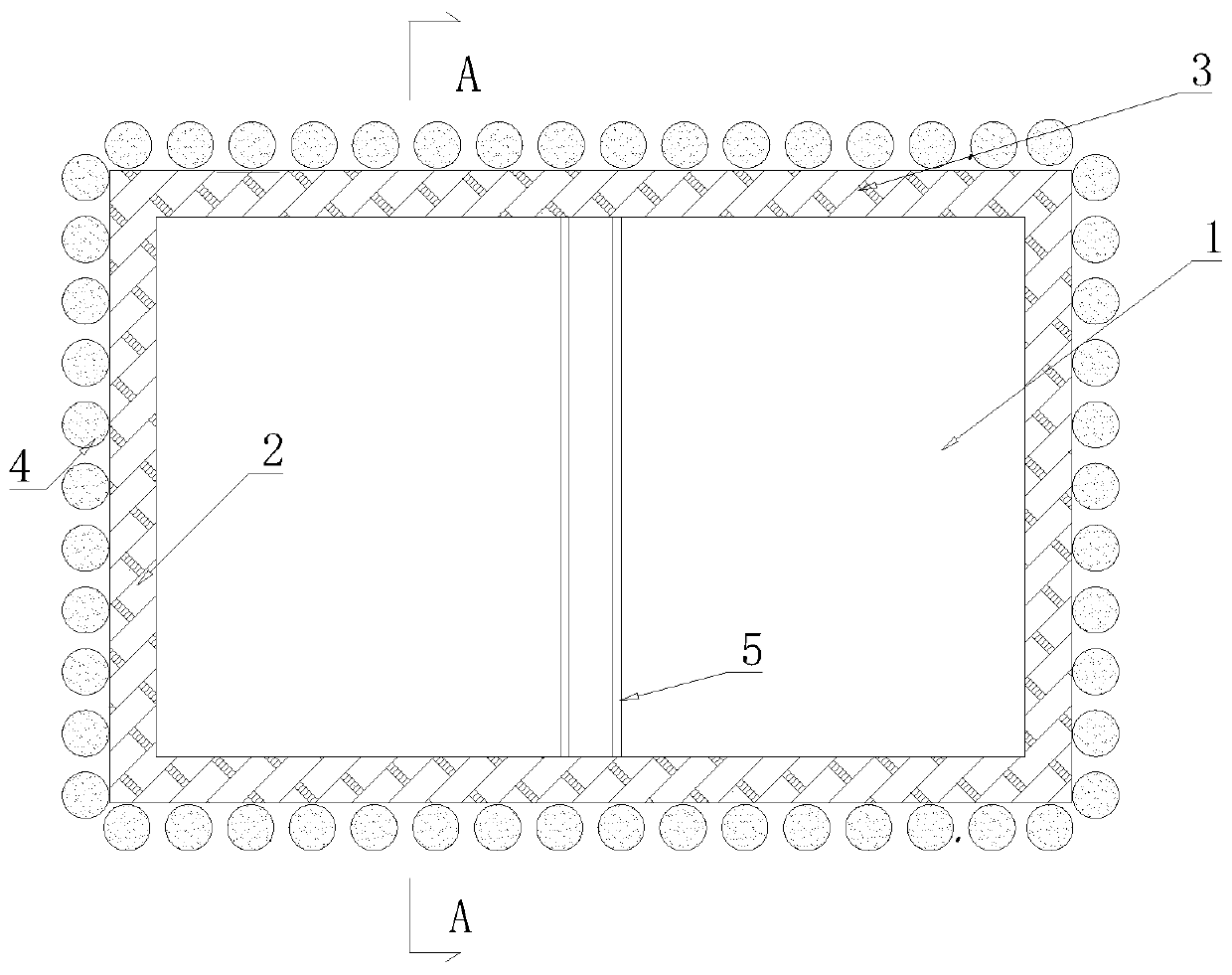

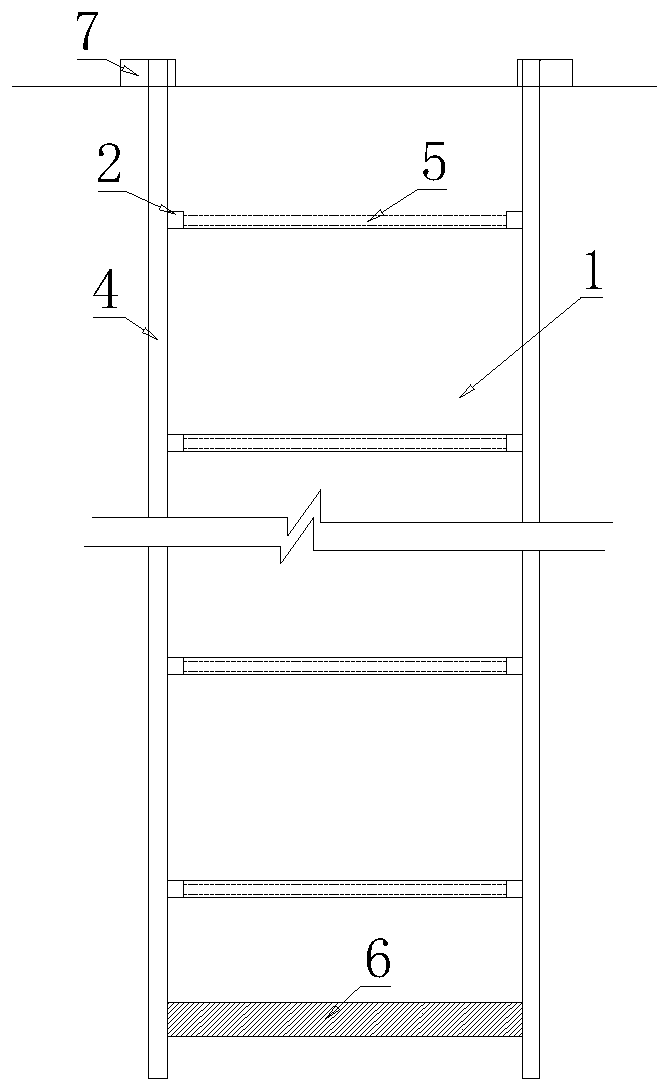

[0039] Such as Figure 1-2 As shown, the present embodiment provides artificial excavation pile pre-reinforced retaining wall structure, including multiple groups of prefabricated waist beams, a plurality of reinforcement pipes 4, pile well locks 7 and cross braces 5;

[0040] The artificially dug pile pile well 1 is a rectangular structure.

[0041] Multiple groups of prefabricated waist beams are arranged at intervals along the depth direction of the pile well 1. One set of prefabricated waist beams includes two short-side waist beams 2 and two long-side waist beams 3. Two short sides and two long side waist beams 3 are respectively located on the two long sides of the pile shaft 1, and the two short side waist beams 2 and the two long side waist beams 3 are fixedly connected to form a rectangular frame structure. Specifically, multiple groups of prefabricated The distance between the waist beams along the depth direction of the pile well 1 is 0.5-1m. The two short side wai...

Embodiment 2

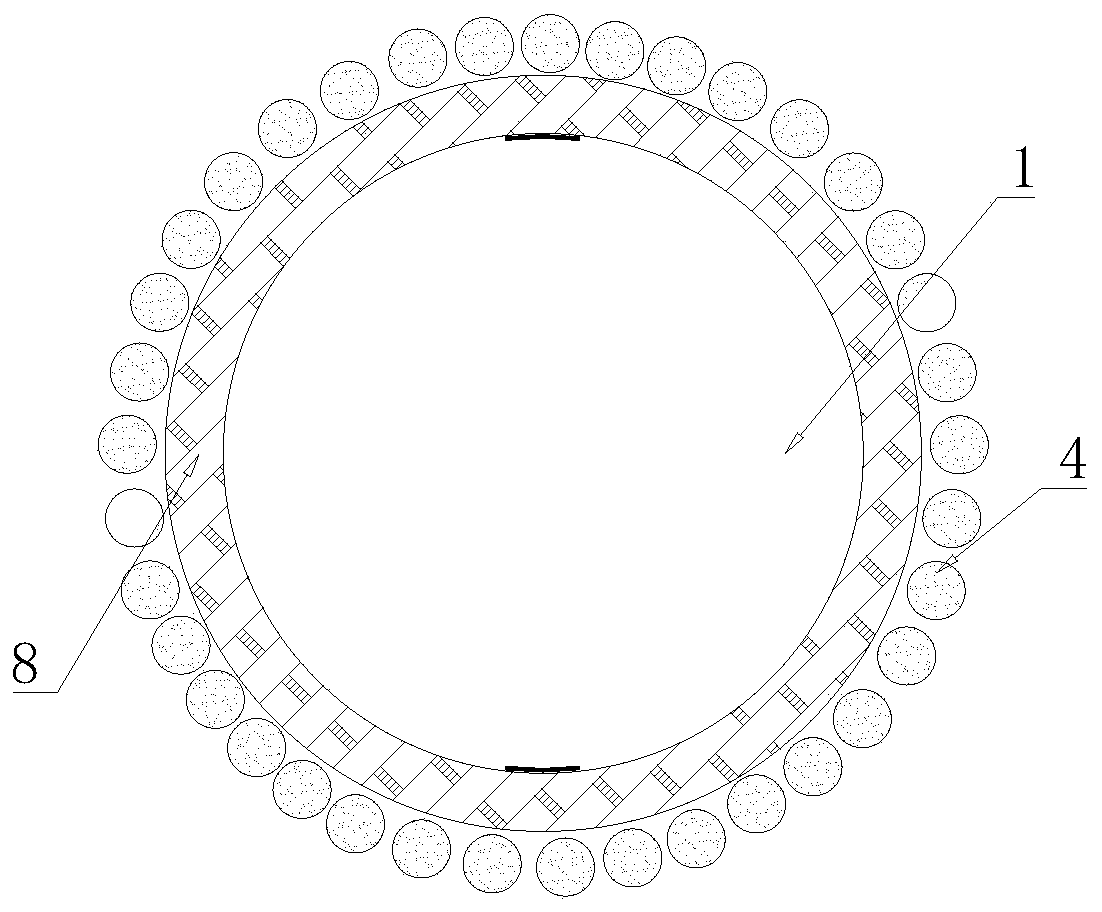

[0070] Such as image 3 As shown, the present embodiment provides a pre-reinforced retaining wall structure for artificial digging piles, including an annular waist beam 8, a plurality of reinforcement pipes 4 and pile well locks 7;

[0071] The artificially dug pile pile well 1 is a circular structure.

[0072] The annular waist beams 8 are arranged at intervals along the depth direction of the pile well 1. Specifically, the spacing of the annular waist beams 8 along the depth direction of the pile well 1 is 1-3m. Use I-beam, section steel or scrap steel rail, and grid steel frame can also be used.

[0073] A plurality of reinforcement pipes 4 are arranged at intervals along the circumferential direction of the pile well 1, fillers are poured in the reinforcement pipes 4, the tops of the reinforcement pipes 4 protrude from the pile well 1, and the reinforcement pipes 4 are fixedly connected with the annular waist beam 8. Specifically, the reinforcement pipes The layout, sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com