Basement thick-and-large base plate rebar support and construction method thereof

A steel support and basement technology, applied in the direction of basic structure engineering, structural elements, wine cellars, etc., can solve the problems of inconvenient construction operations, high material consumption, and large labor workload, so as to improve construction quality and safety, and facilitate construction operations , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

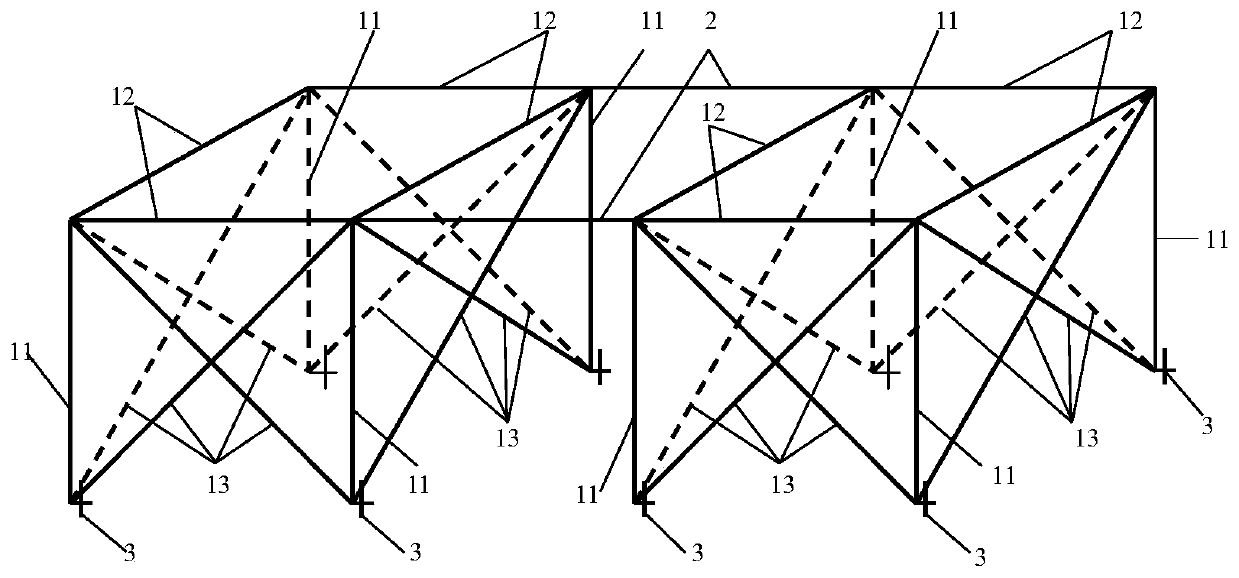

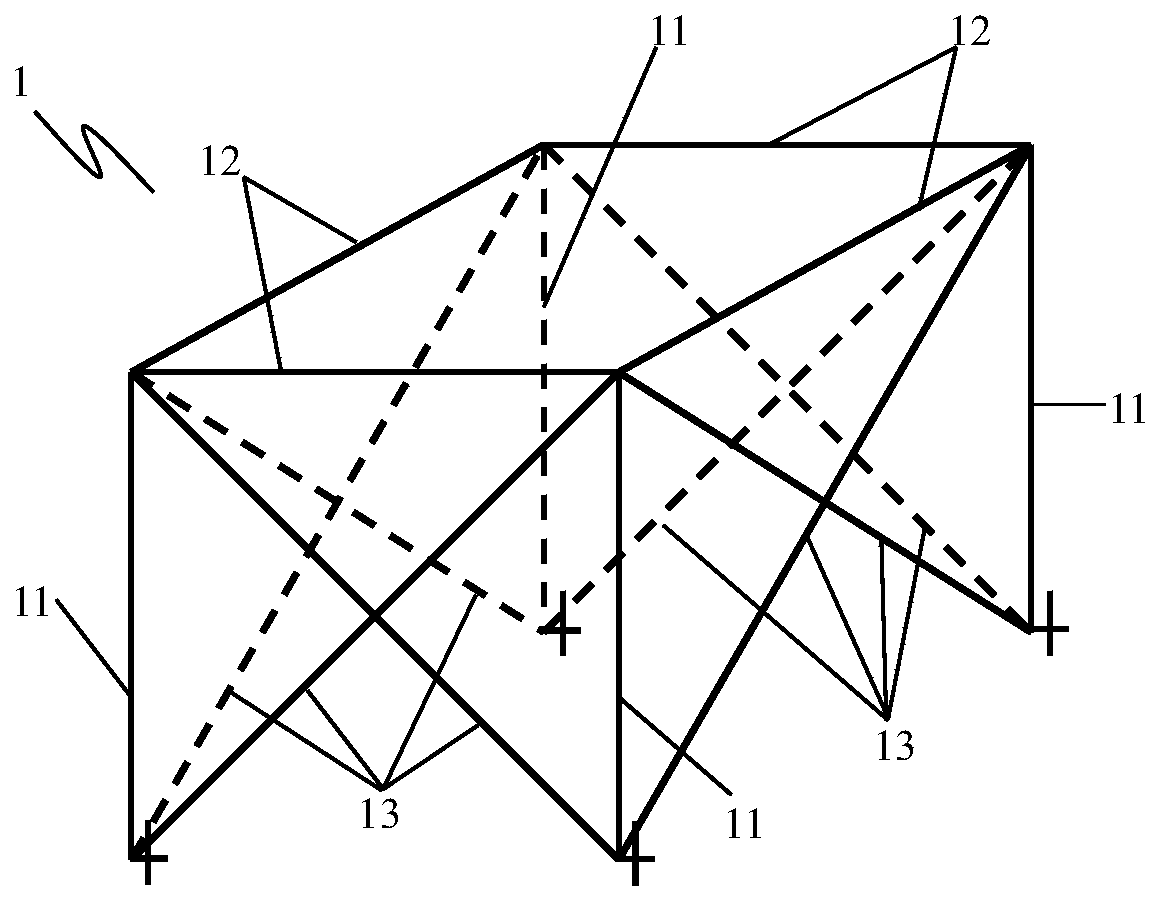

[0029] see Figure 1 to Figure 4 As shown, the present invention relates to a steel bar support for a thick basement floor, including a plurality of steel bar support unit modules 1, a plurality of first horizontal bars 2, and a plurality of adjustable bolts 3; each of the steel bar support unit modules 1 includes at least four Upright rods 11, at least four second horizontal rods 12 and at least eight diagonal braces 13; every four of the second horizontal rods 12 form a rectangle, and each of the upright rods 11 is vertically arranged At the junction of the two second horizontal rods 12, one end of each of the diagonal bracing rods 13 is supported at the joint between the column rod 11 and the second horizontal rod 12, and the other end is fixedly supported on the adjacent column. the bottom of the rod 11;

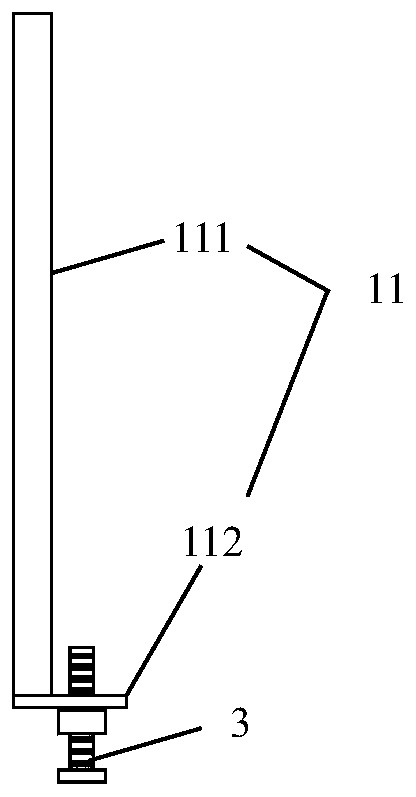

[0030] Each of the uprights 11 includes a upright 111 and a base 112, the base 112 is welded to the bottom of the upright 111, and the base 112 is provided with a bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com