Micro-prestress self-resetting wall provided with self-resetting variable friction dampers and construction method thereof

A micro-prestressing and self-resetting technology, which is applied in the direction of building components, building types, and earthquake resistance, can solve the problems that earthquake resistance cannot play a beneficial role, the requirements for local pressure of concrete are difficult to meet, and the structural ductility is reduced. It is easy to achieve Quantitative representation, improved shear resistance, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

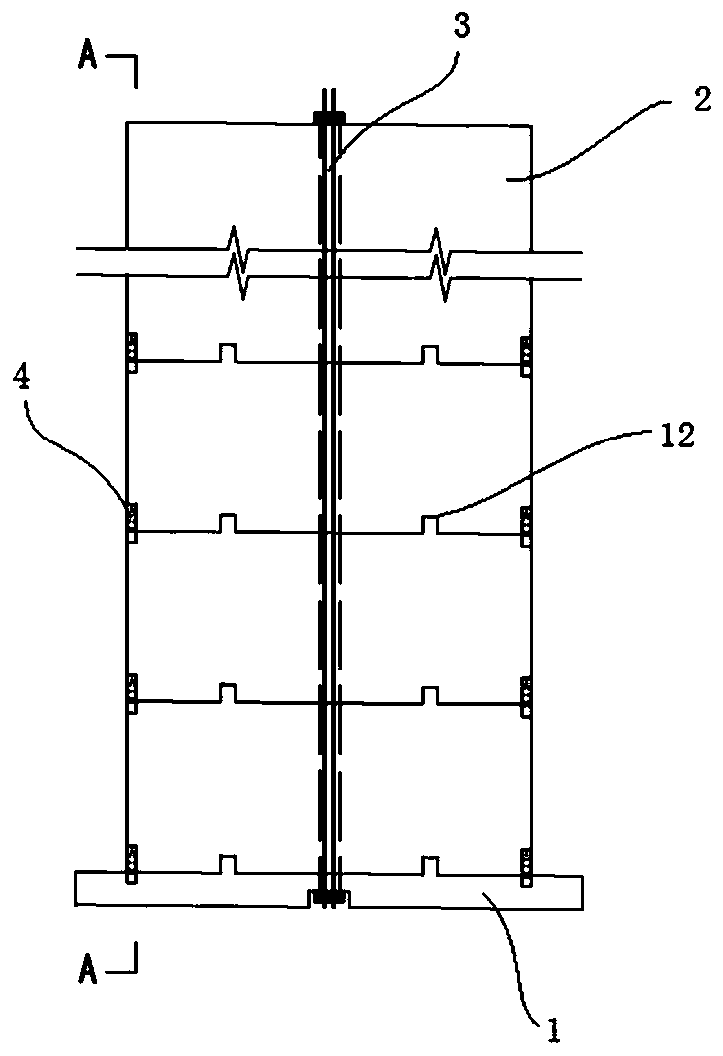

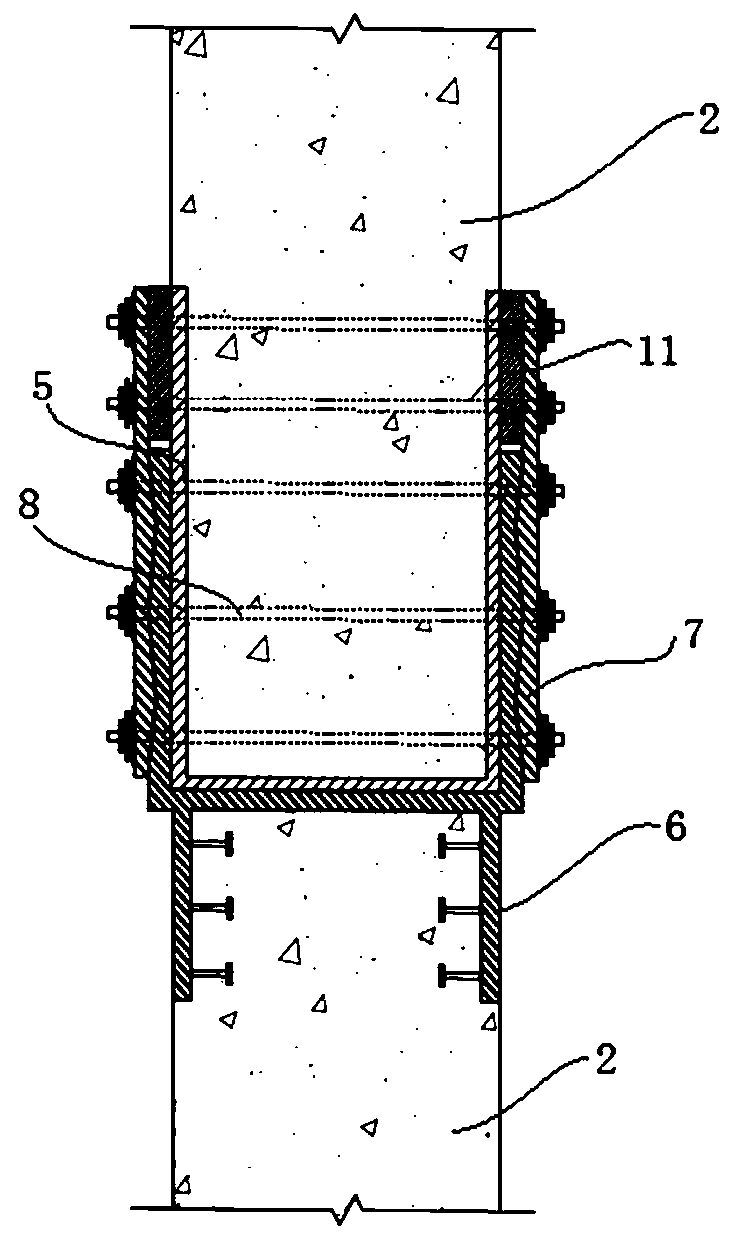

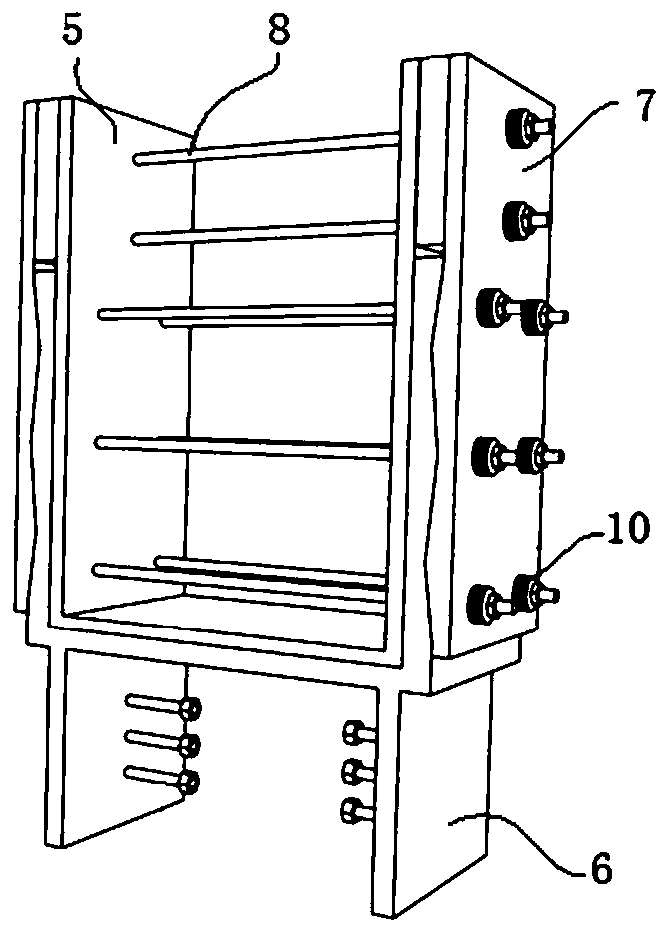

[0024] The micro-prestressed self-resetting wall of the present invention is mainly used to improve the energy dissipation capacity of the assembled concrete prefabricated wall under the earthquake action, and can effectively eliminate or reduce the residual deformation of the structure under the earthquake action under the condition of applying micro-stress , and improve the shear capacity of the wall and the assembly efficiency of the structure. Such as figure 1 and figure 2 As shown, specifically, the micro-prestressed self-resetting wall includes a prefabricated foundation beam 1 provided with a shear key 12 and several sections of prefabricated concrete horizontal walls 2 that are arranged on the foundation beam 1 and contain a shear key 12. The main component, and the connection component composed of the fully self-resetting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com