Intelligent control type heat exchange unit

A technology of heat exchange unit and intelligent control, which is applied in household heating, heating methods, household heating, etc., can solve problems such as shortened service life, heat exchange efficiency needs to be improved, and easily damaged internal pipelines of plate heat exchangers, etc. To achieve the effect of easy cleaning and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

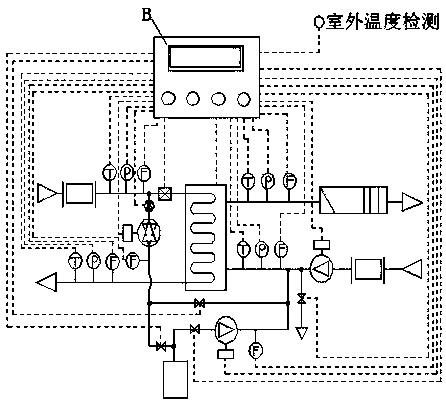

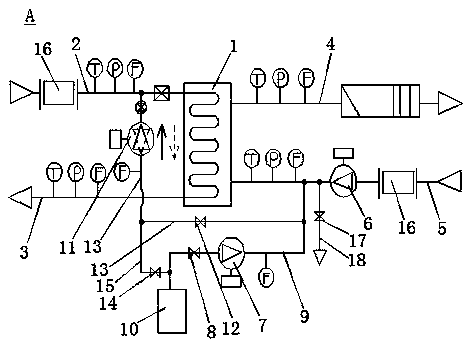

[0016] Such as figure 1 with figure 2 The intelligent control heat exchange unit shown is composed of a heat exchange unit A and a PLC control cabinet B for complete machine control; the heat exchange unit A includes a primary heat exchanger with a data acquisition device connected to the plate heat exchanger 1 The network circulation pipeline and the secondary network circulation pipeline; the data acquisition device is communicatively connected with the PLC control cabinet B; the primary network circulation pipe routes the primary network water supply pipeline 2 and the primary network return water pipeline 3 with regulating valves Composition; The secondary network circulation pipe is composed of a secondary network water supply pipeline 4 and a secondary network return water pipeline 5; the secondary network return pipeline 5 is connected with a secondary network circulation pump group 6; The network circulating pump group 6 has a secondary network return water pipeline 5 o...

Embodiment 2

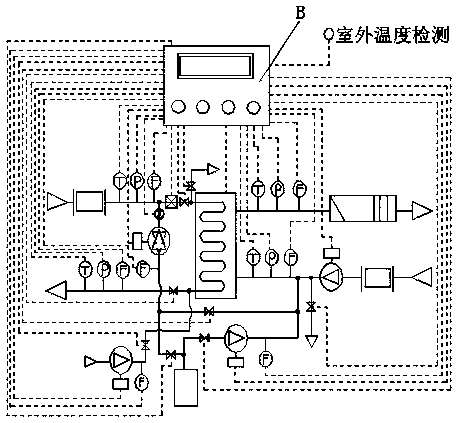

[0021] Such as image 3 with Figure 4 The structure of the intelligent control heat exchange unit shown is basically the same as that of the first embodiment. Among them, it also includes a backwashing pipeline arranged on one side of the primary network circulation pipeline; the backwashing pipeline includes a plate heat exchanger 1 The return water side of the primary network is connected to the water inlet pipe 21 with the flushing pump set 20 through the backflushing water inlet switching valve 19, and to the plate heat exchanger 1 The water supply side of the primary network is connected through the backflushing water outlet switching valve 22 The outlet pipe 23; the plate heat exchanger 1 is installed between the primary network return water side and the primary network return water pipeline 3 with a backwater switching valve 24; the plate heat exchanger 1 has a primary network water supply side and a primary A water supply switching valve 25 is installed between the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com