Efficient transcritical carbon dioxide refrigerating system

A carbon dioxide and refrigeration system technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing the manufacturing cost of CO2 systems, and achieve the effects of increasing energy efficiency ratio, reducing use, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

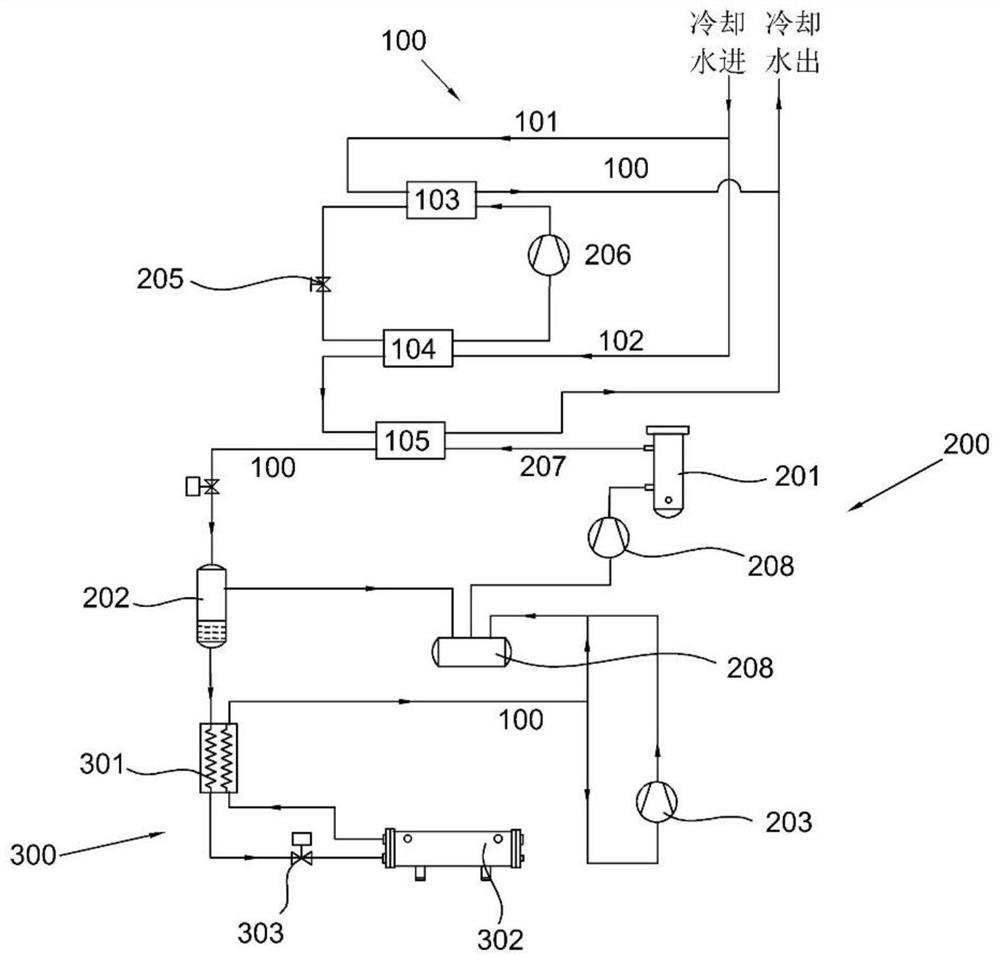

[0031] refer to figure 1 , the present invention discloses a high-efficiency transcritical carbon dioxide refrigeration system, including a water inlet assembly 100, including a first water inlet pipe 101, a second water inlet pipe 102 extending from the first water inlet pipe 101, and a The second condenser 103 on the water pipe 101 and the second evaporator 104 arranged on the second water inlet pipe 102, the end of the second water inlet pipe 102 away from the second evaporator 104 is provided with a gas cooler 105, the first water inlet pipe 101 and The far end of the second water inlet pipe 102 is connected to the water outlet pipe; the compression assembly 200 includes an oil fraction 201, a flash tank 202 connected to the oil fraction 201, and a first low-pressure stage compressor 203 connected to the water outlet of the flash tank 202; and, back to The heat component 300 and the heat recovery component 300 are arranged between the flash tank 202 and the first low-press...

Embodiment 2

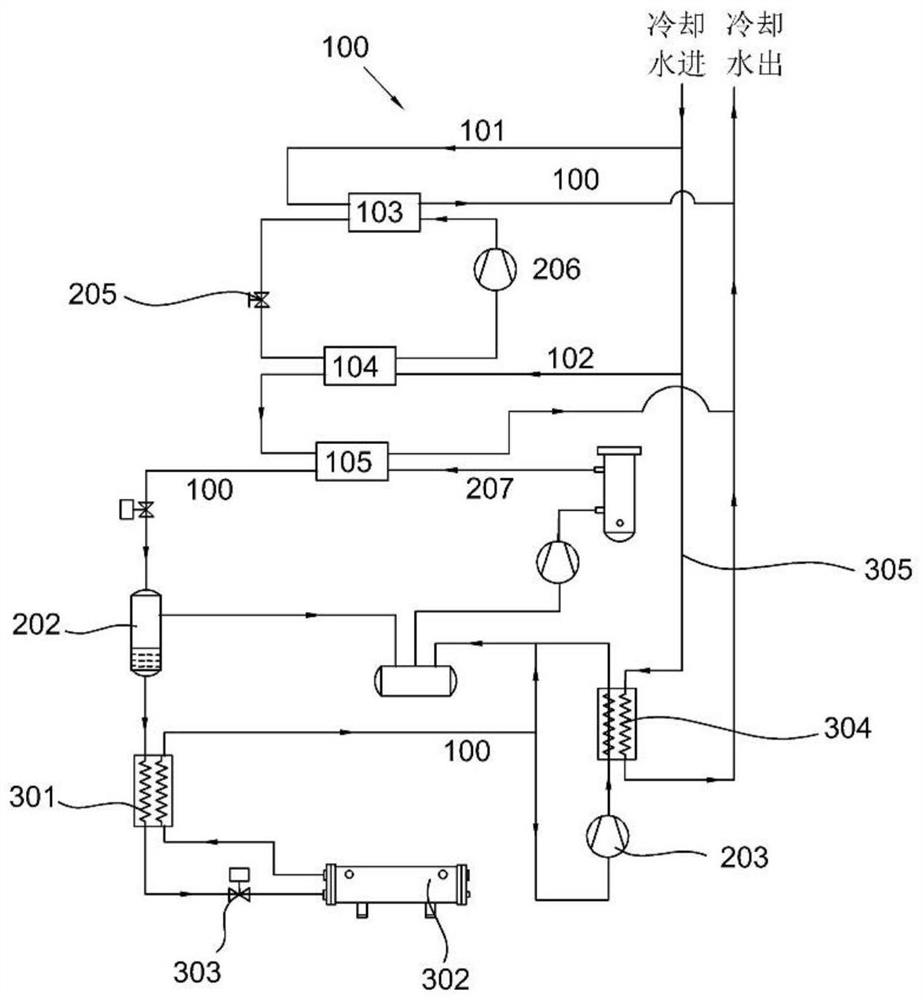

[0040] refer to figure 2 , this embodiment is different from the first embodiment in that: the first low-pressure stage compressor 203 is connected with a precooler 304, the second water inlet pipe 102 extends from the third water inlet pipe 305, and the third water inlet pipe 305 passes through The precooler 304 is connected to the outlet pipe afterward, and the first evaporator 302 is a sleeve-and-tube heat exchanger.

[0041] Specifically, on the basis of Implementation 1, the first low-pressure stage exhaust precooler 304 is added to reduce the exhaust temperature of the first low-pressure stage compressor 203 to 30-35°C through cooling water, further reducing the temperature of the first high-pressure stage compressor. The suction superheat degree of 209 also reduces the discharge temperature of the first high-pressure stage compressor 209, so that the discharge temperature of the compressor is controlled within the optimal range; in addition, the suction density of the ...

Embodiment 3

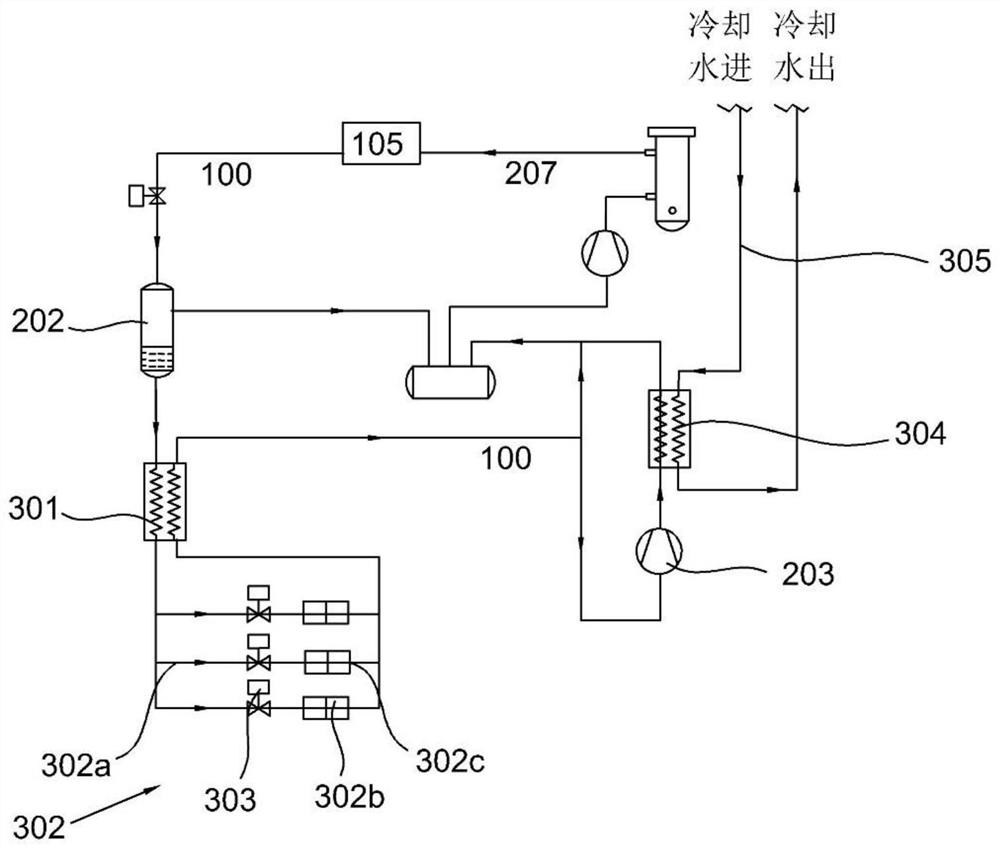

[0044] refer to image 3 , this embodiment is different from the above embodiments in that: the first evaporator 302 includes several branch pipes 302a protruding from the regenerator 301, a cooling fan 302b arranged on each branch pipe 302a, and a cooling fan 302b arranged on the cooling air The discharge pipe 302c on the machine 302b is connected to the regenerator 301 after the ends of several branch pipes 302a are connected.

[0045] All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com