Large motor bearing fault diagnosis device

A fault diagnosis device and a technology for large motors, which are applied in the direction of mechanical bearing testing, etc., can solve the problems such as the lack of a better protective device for the diagnosis of firearms, insufficient protection of the root of the wire tube, and easy breakage of the wire tube, so as to avoid falling and using Safety and longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

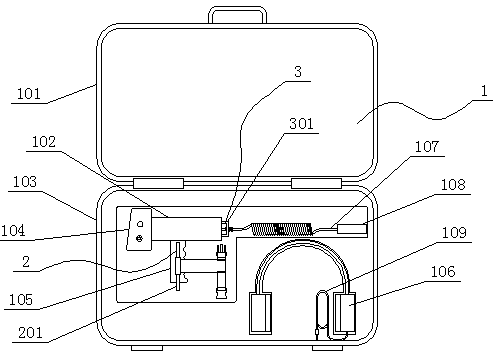

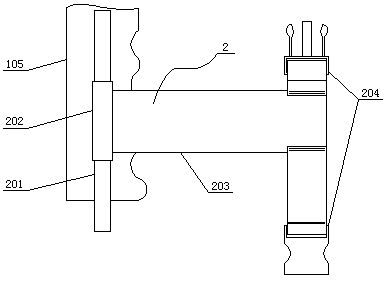

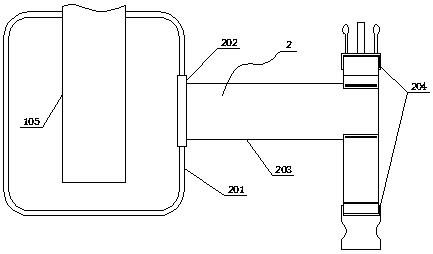

[0018] see Figure 1-Figure 6 , the present invention provides the following technical solutions: a large-scale motor bearing fault diagnosis device, including a bearing diagnosis structure 1, a diagnosis gun support structure 2 and a line pipe support structure 3, and the bearing diagnosis structure 1 includes an upper box cover 101, a box base 103. Diagnosis gun barrel 102 and diagnostic earphone 106, the upper box cover 101 and the box base 103 are connected and fixed by a rotating shaft, the diagnostic gun barrel 102 and the diagnostic earphone 106 are both engaged and fixed inside the box base 103, the wire The tube support structure 3 is fixed on the tail end of the diagnostic gun barrel 102, and one side of the diagnostic gun barrel 102 is provided with a diagnostic gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com