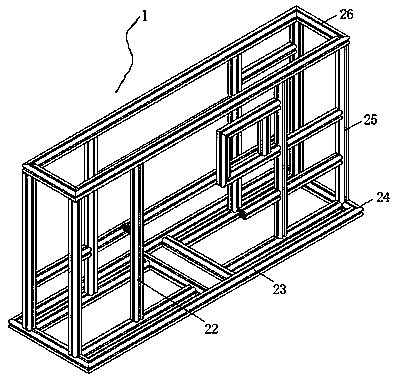

Simple assembling experiment device for teaching based on three-dimensional space mechanism

An experimental device, three-dimensional space technology, applied in educational appliances, teaching models, instruments, etc., can solve the problems of cumbersome operation, large volume, unfavorable teaching purposes, etc., and achieve the effect of flexible economic cost, small size, and exercise structural innovation ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

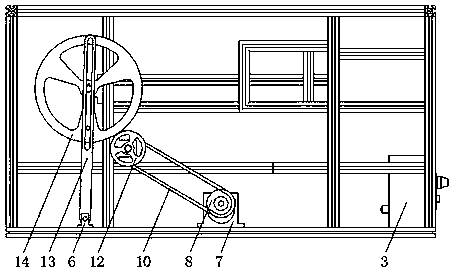

[0047] Such as image 3 As shown, the electrical box is installed at the end of the three-dimensional frame, the driving motor is installed on the two short beams in the middle of the bottom frame, and the connecting shaft is installed at the position of the three-dimensional frame above the left obliquely above the driving motor. V-belt pulleys are arranged on the shaft respectively, and the two V-belt pulleys are connected by a belt to form a belt transmission mechanism. Turn on the power switch of the electrical box and adjust the motor debugging knob to make the drive motor drive the belt transmission mechanism to run. Install another connecting shaft at a suitable position on the three-dimensional frame, and install a large spur gear and a small spur gear on the two connecting shafts to form an external gear mechanism. The external gear mechanism can run together with the belt transmission mechanism. The bearing support is installed on the cross beam of the bottom frame, ...

Embodiment 2

[0049] Such as Figure 4 As shown, the worm gear and worm mechanism are installed on the three-dimensional frame above the driving motor through the bearing support, and the small bevel gear is connected to the end of the worm, and the large bevel gear is fixed on the three-dimensional frame through the connecting shaft, and connected with the small bevel gear The conical gear mechanism is formed by meshing with each other. At the same time, a V-belt pulley is installed on the connecting shaft of the large bevel gear, and a V-belt pulley is installed coaxially with the output shaft of the driving motor. The two V-belt pulleys are connected by a belt to form a new one. belt drive mechanism.

Embodiment 3

[0051] Such as Figure 5 As shown, the mechanical structures of embodiment 1 and embodiment 2 are connected through the belt transmission mechanism, and the motor is driven to move, and the belt transmission mechanism of embodiment 1 is driven to operate while the belt transmission mechanism of embodiment 2 can also be driven to operate. Embodiment 2 The operation of the belt transmission mechanism can drive the operation of the conical gear mechanism, and the operation of the conical gear mechanism drives the operation of the worm gear mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com