Auxiliary structure for adhesive connection of metal bipolar plate flow field area of fuel cell

A metal bipolar plate and fuel cell technology, which is applied in the direction of fuel cell additives, fuel cell parts, fuel cells, etc., can solve the problems of plate function failure, welding without welding area, and affecting the flatness of the plate. Achieve the effect of increasing flow resistance and improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

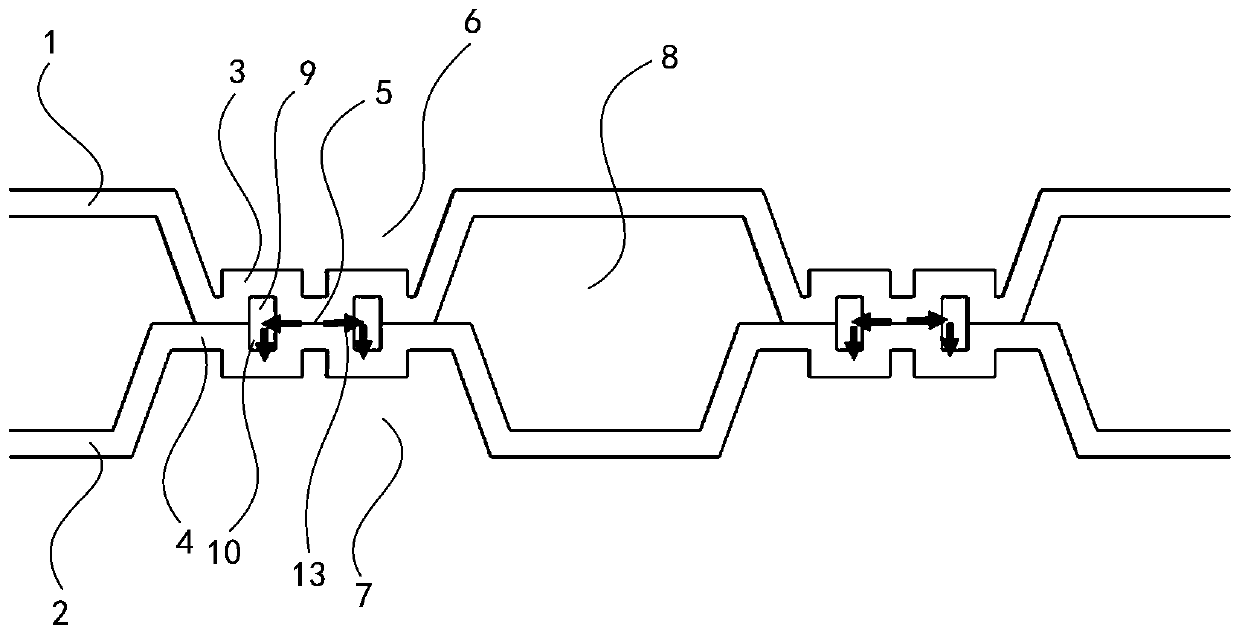

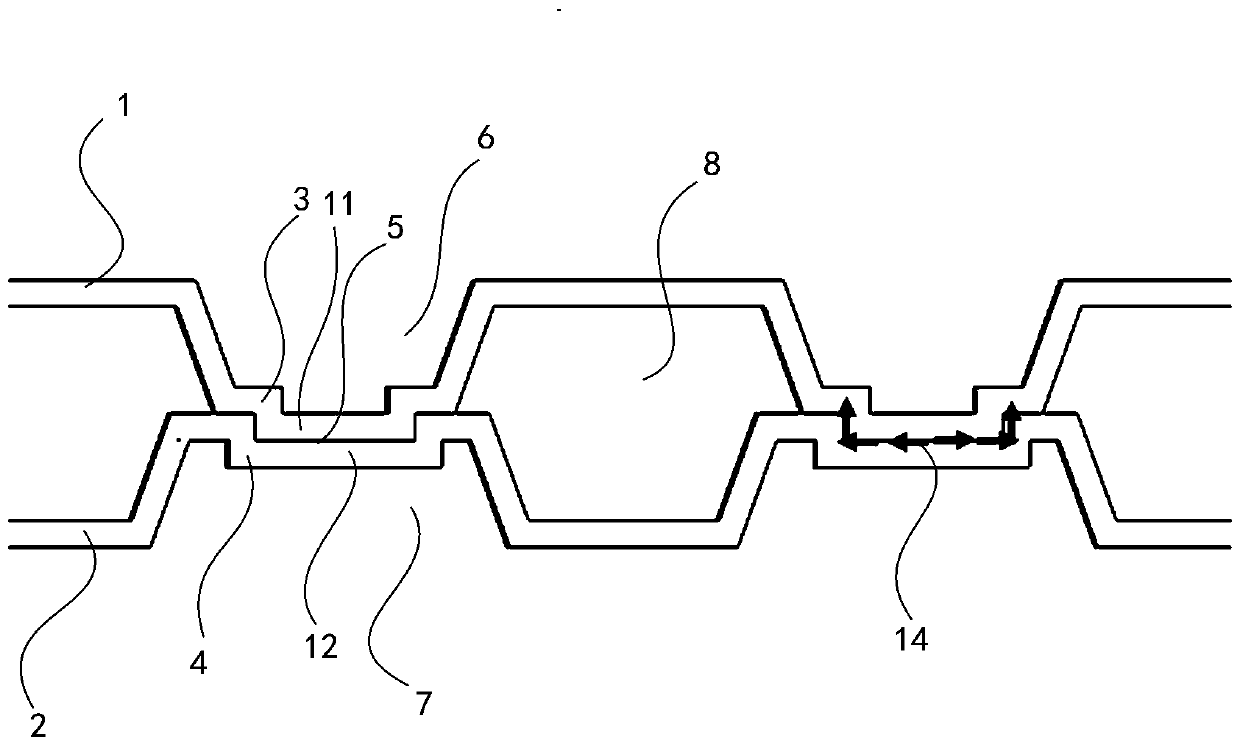

[0015] The invention discloses an auxiliary structure for the adhesive connection of the flow field area of the metal bipolar plate of the fuel cell, such as figure 1 As shown in , it is the first embodiment of the present invention, which is different from the prior art in that: it includes an anode plate 1 and a cathode plate 2, and the anode plate 1 forms several raised forward flow lines toward the cathode plate 2. The channel ridges 3, the cathode plate 2 form a number of reverse channel ridges 4 that protrude in the direction of the anode plate 1, and the forward channel ridges 3 and the reverse channel ridges 4 are distributed in one-to-one correspondence The contact surface of the forward flow channel ridge 3 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com