Cable joint connection branch box

A technology of cable joints and branch boxes, applied in the direction of cable joints, etc., can solve the problems of no isolation protection, cable damage to the cable head, etc., achieve beautiful appearance, improve construction efficiency, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

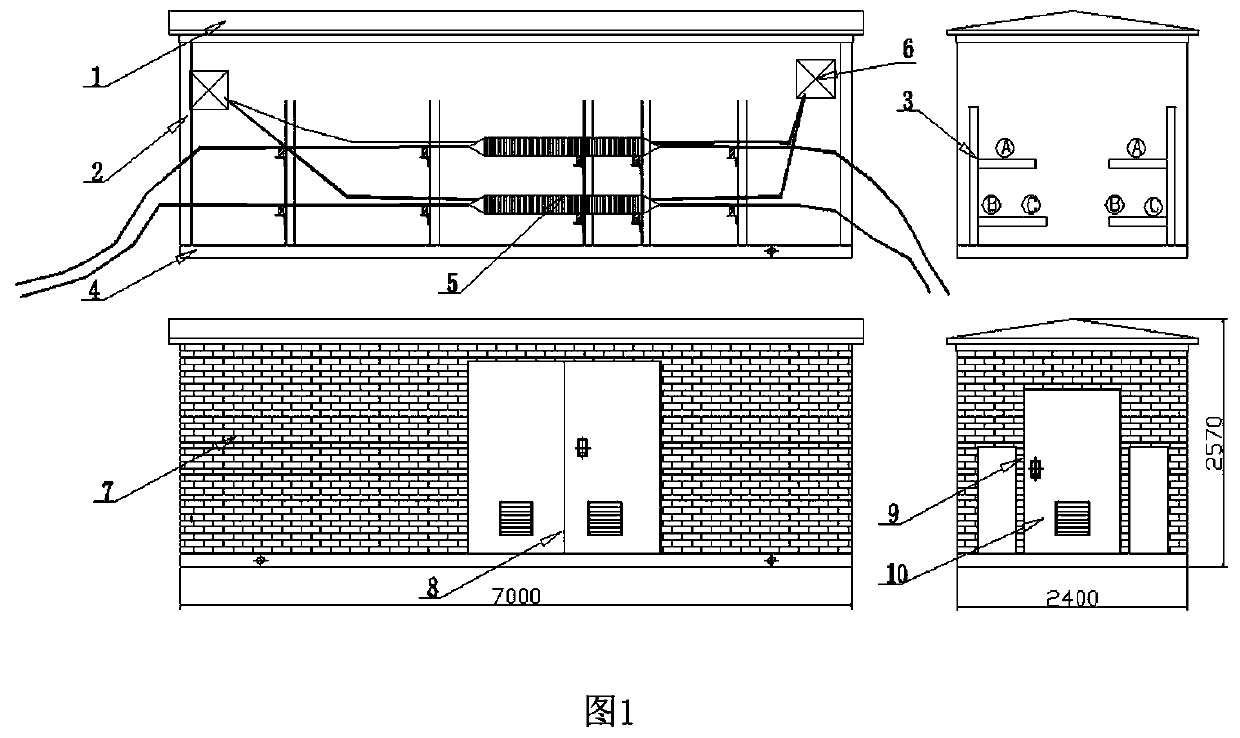

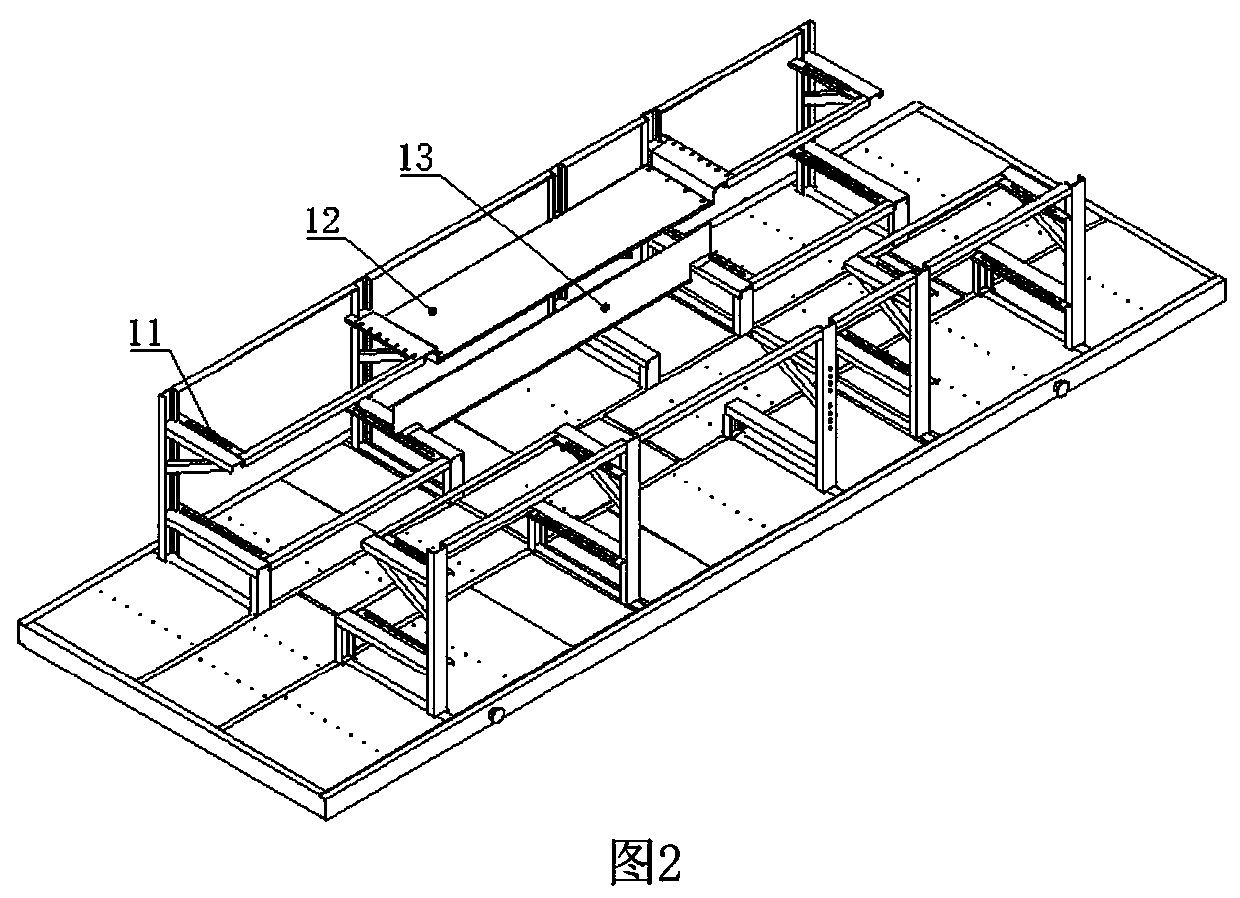

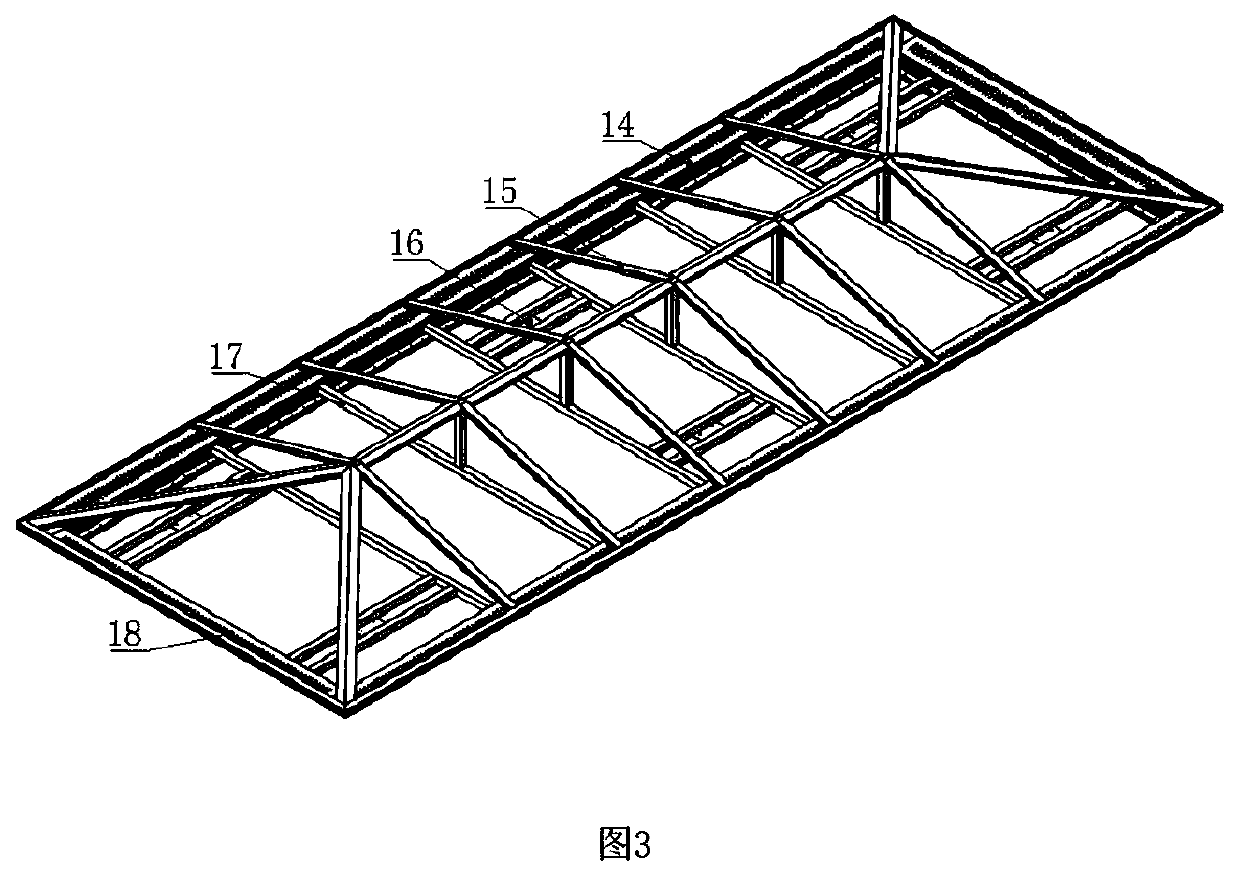

[0014] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. A cable joint connection branch box, including a box top cover 1, a box frame 2, a cable joint bracket 3, a skid-mounted chassis 4, a high-voltage cable joint 5, a grounding protection box 6, a decorative composite board 7, an inspection door 8, a high-voltage The cable inlet 9, the access door 10, the box top cover 1, the box frame 2, the cable joint bracket 3, and the skid-mounted chassis 4 are welded by galvanized profiles, and the box top cover 1 is located at the top of the branch box , the cable joint bracket 3 is fixed on the skid-mounted chassis 4, and the box frame 2 is located between the box top cover 1 and the skid-mounted chassis 4; the ground protection box 6 is fixed inside the box frame 2 with bolts, and the The access door 8 and the access door 10 are fixed on the box frame 2 through stainless steel hinges, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com