Anti-shake system for micro camera

A micro-camera and anti-shake technology, which is applied to the focus device of the camera, the focus device of the projector, and the printing device, etc., can solve the problems of blurred images, complex procedures, blurred images in four corners, etc., and achieve a rapid increase in the pass rate of production capacity , fast and precise production, superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

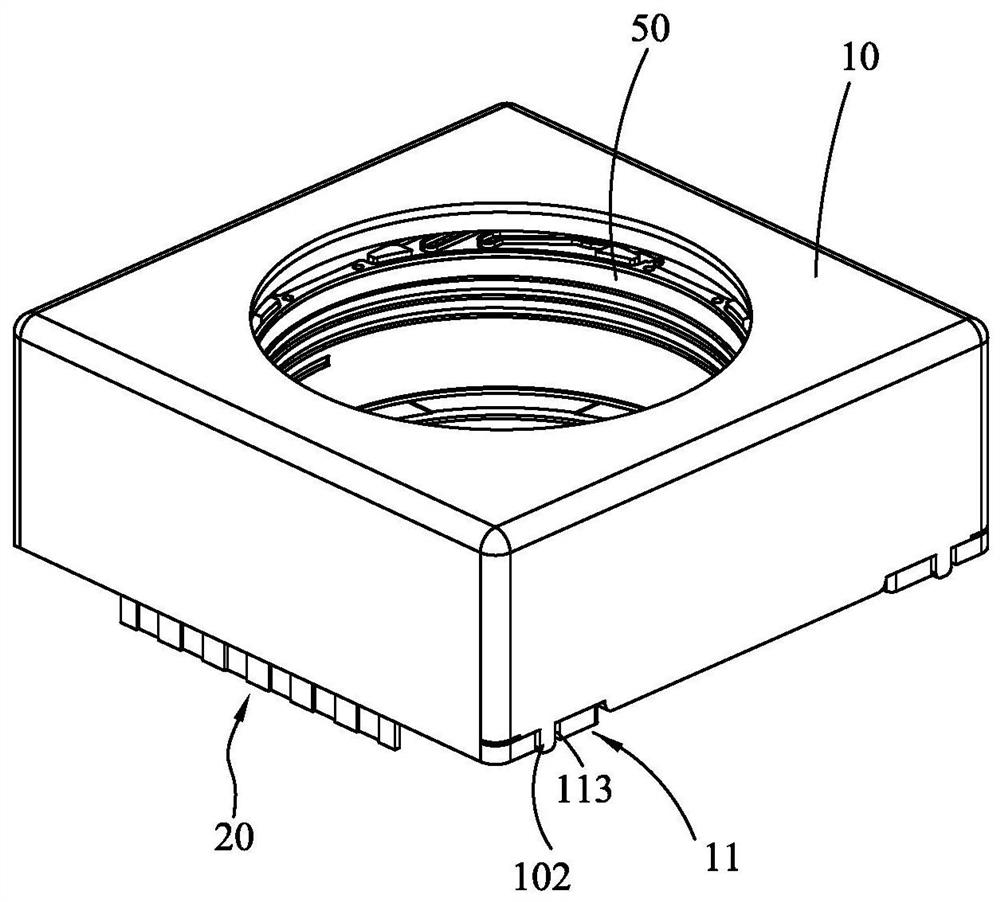

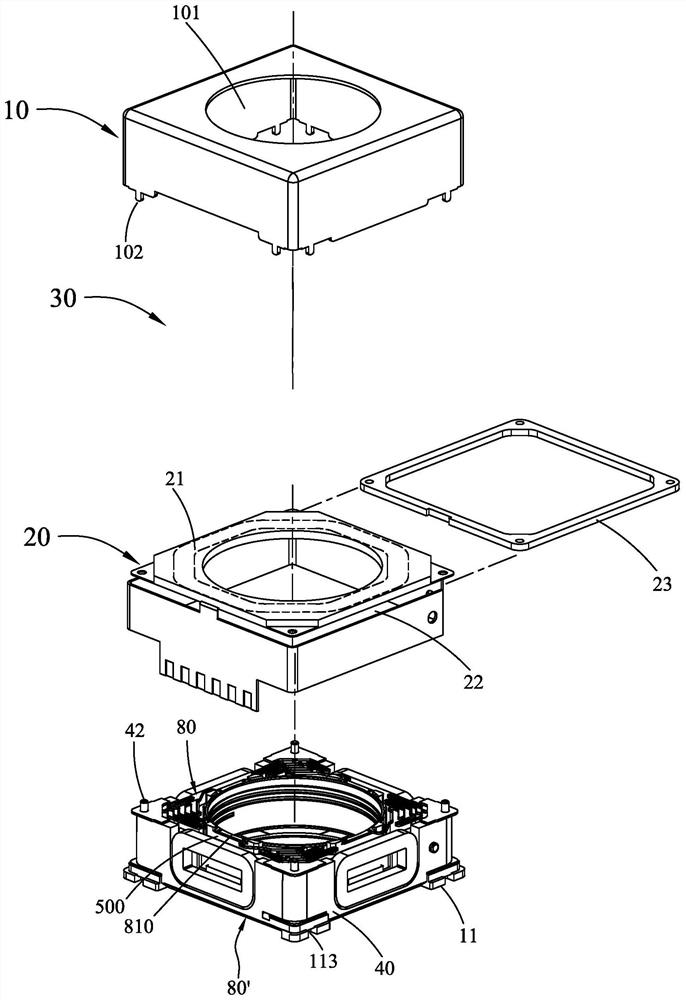

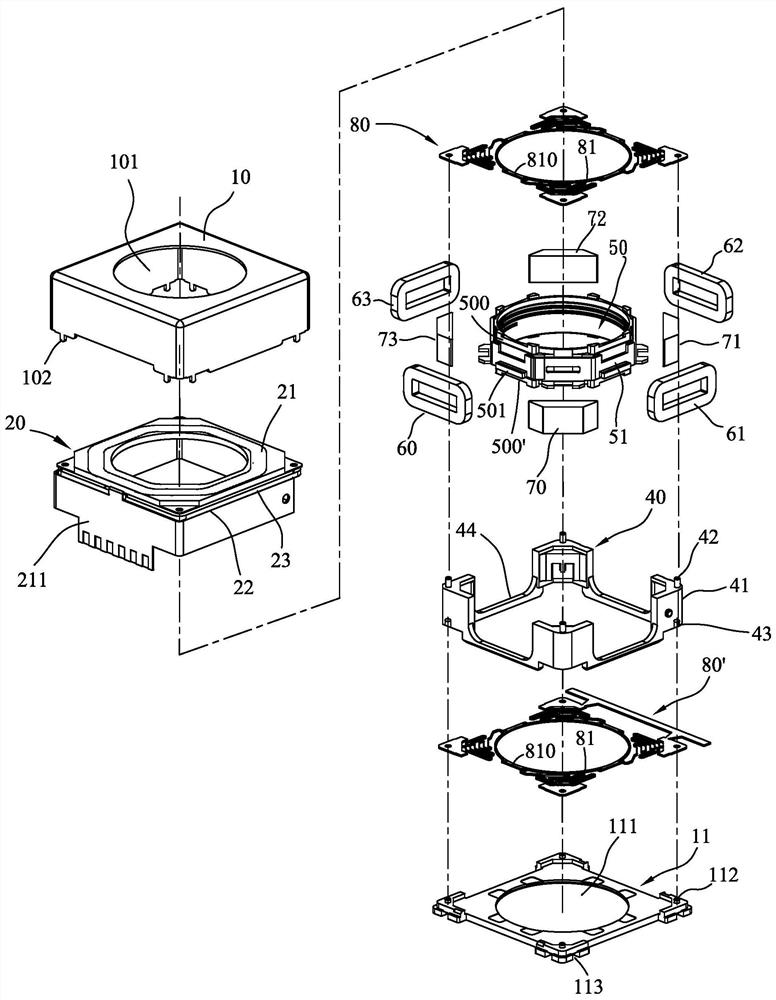

[0058] A flexible circuit board 20, disposed inside the outer casing, has a flexible board coil 21 in a horizontal direction, and is formed by the flexible board

[0059] Please refer to FIG. 1, FIG. 2, and FIG. 3, a bracket 40 with four corner seats 41 is attached to the flexible circuit board 20

[0064] Please refer to Fig. 3, Fig. 4, Fig. 11, Fig. 12 for the suspension system supporting the mover portion, an upper elastic piece 80 and a lower elastic piece

[0067] Please refer to the upper elastic piece 80A shown in FIG. 15 as another embodiment, which still has as shown in FIG. 3 , FIG. 12 , FIG. 13 , and FIG. 14

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com