Multi-layer ecological pig raising system

An ecological pig raising and floor technology, applied in the direction of organic fertilizer, climate change adaptation, animal houses, etc., can solve the problems of high labor intensity, harsh environment in pig sties, infectious diseases infecting pigs, etc., saving manpower and material resources, processing Good effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

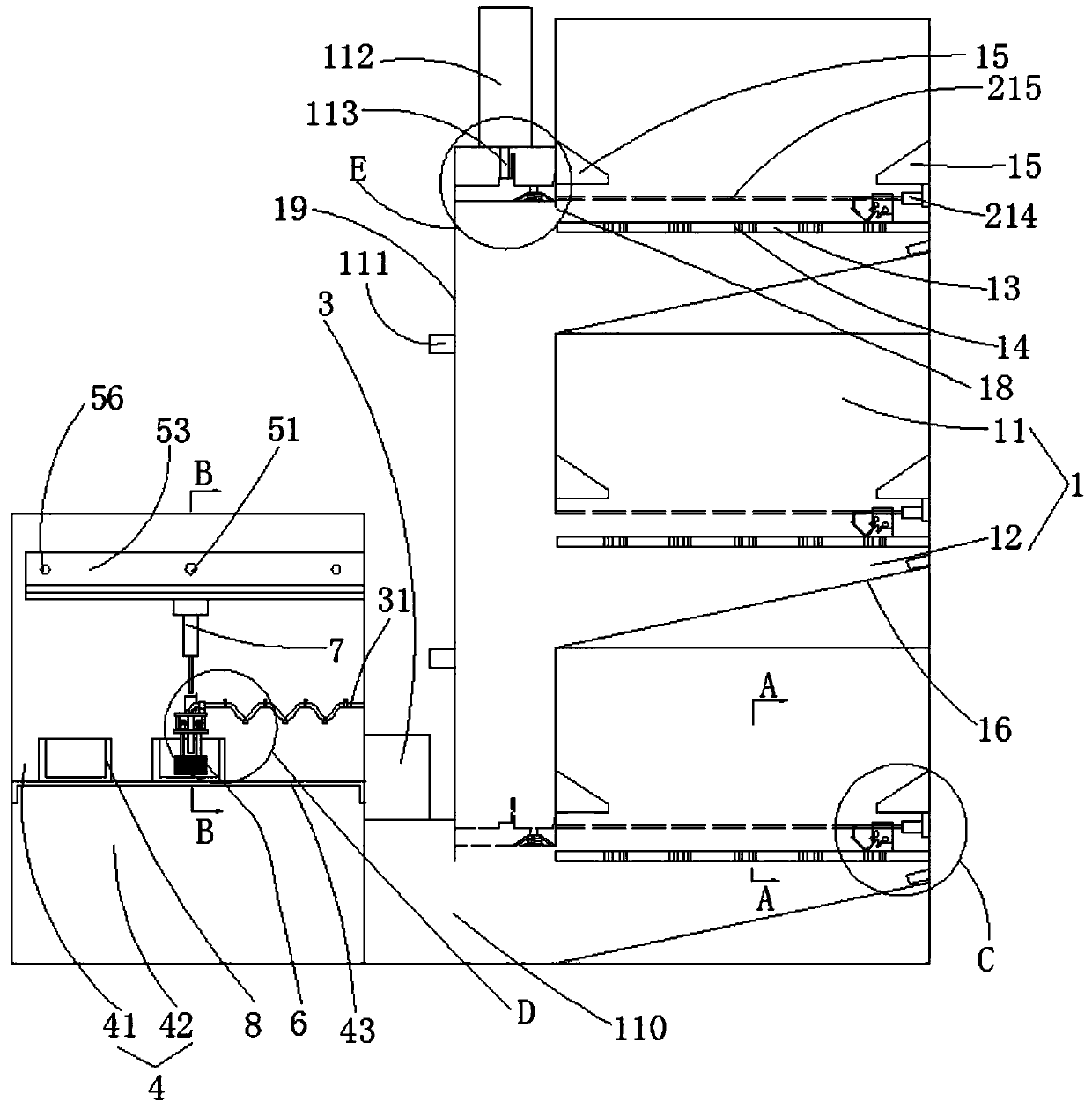

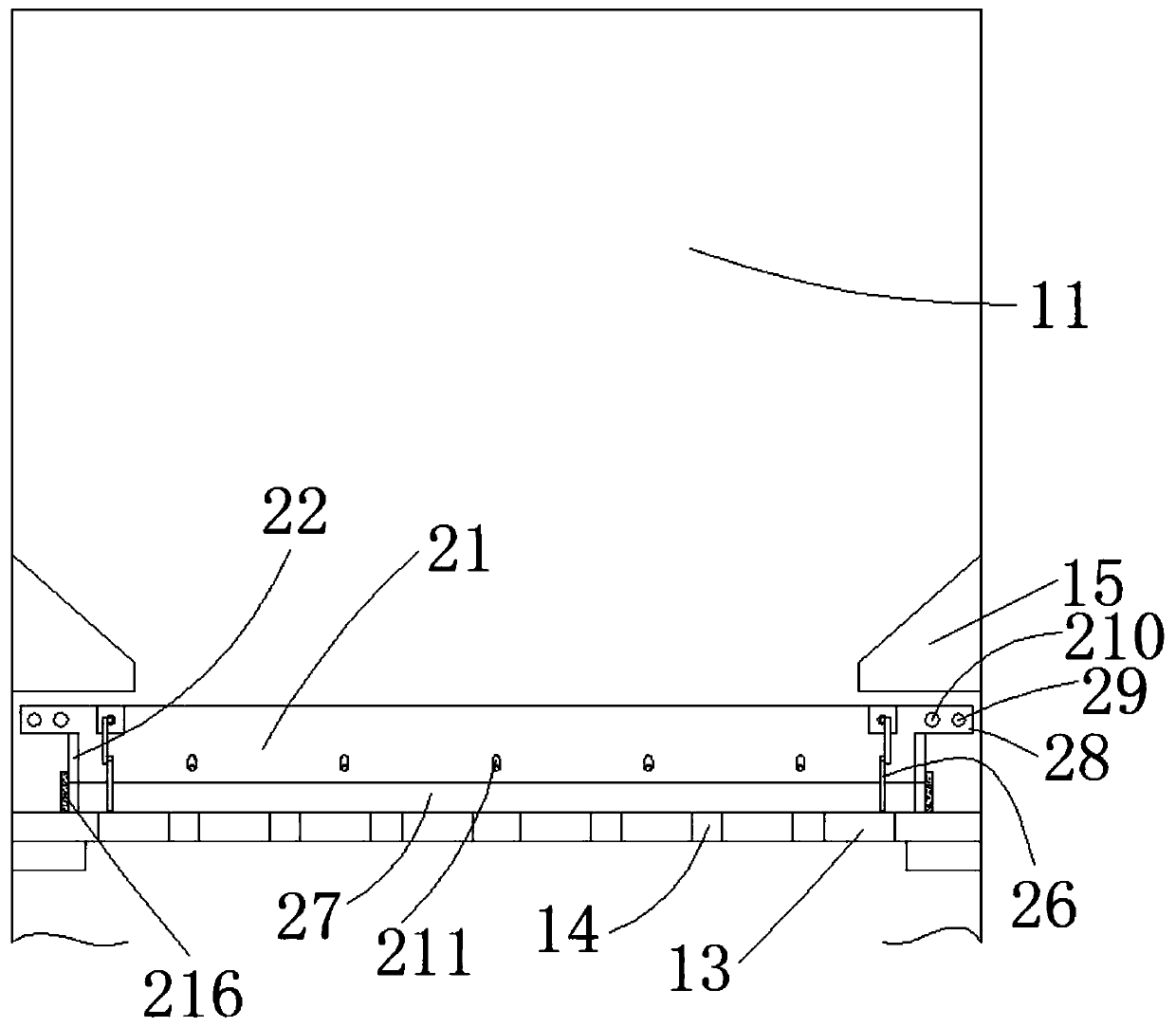

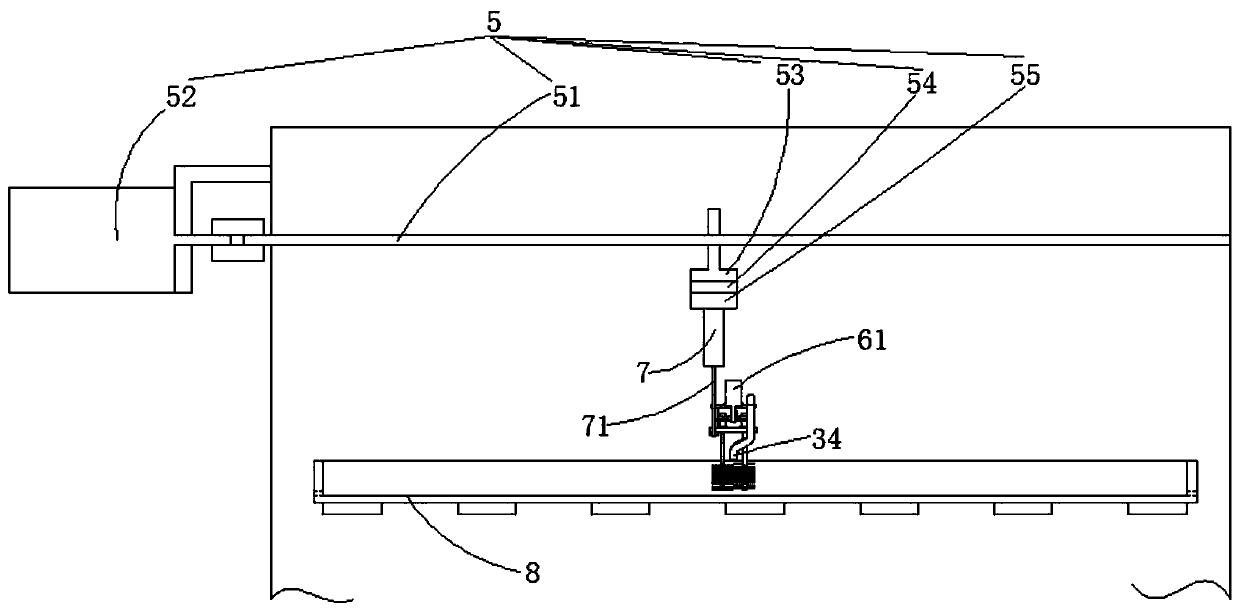

[0032] Such as Figure 1-14As shown, a multi-layer ecological pig raising system includes a treatment room 4 and a plurality of pig raising rooms 1 arranged up and down.

[0033] Each pig house 1 includes a pig room 11 and a collection room 12 separated up and down by a floor 13. The floor 13 can be made of environmentally friendly plastic material. If cement is used to build it, it will affect the skin of the pig. The strength of the floor 13 Can satisfy the weight of pig, perhaps also can be to lay one deck floor 13 on the cement layer after pouring cement, floor 13 and cement layer need perforate simultaneously.

[0034] Pigs are raised in the pig room 11, and the pig room 11 can have windows on multiple sides for collecting light. The pig room 11 is also provided with feed and water tanks for feeding and drinking the pigs. The pigs can be transported by elevators. The piglets are transported to the pig room 11, and the piglets can also be driven into the pig room 11 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com