An Intelligent Vacuum Separation Device

A technology of vacuum separation and separation cylinder, which is applied in separation methods, filtration separation, chemical instruments and methods, etc. It can solve problems such as lack of mixing and stirring function, suspension affecting separation effect, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

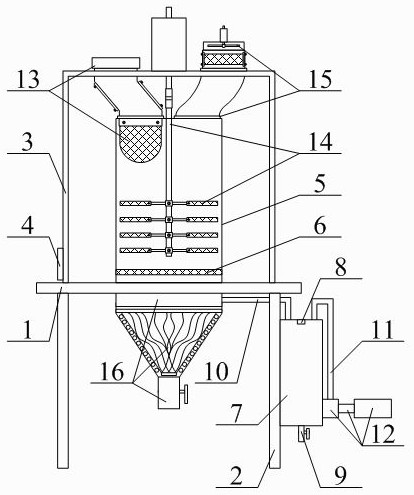

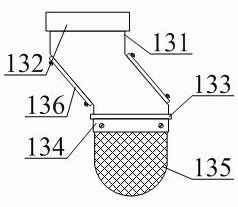

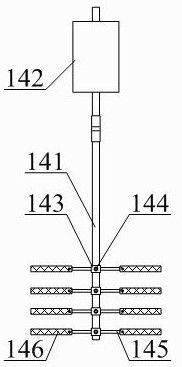

[0035]The present invention is described in detail below in conjunction with accompanying drawing, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of intelligent vacuum separation device comprises frame 1, supporting leg 2, inverted U-shaped bracket 3, intelligent control screen 4, Separation cylinder 5, miscellaneous net 6, liquid storage tank 7, liquid level sensor 8, mechanical discharge valve 9, diversion pipe 10, vacuum pipe 11, vacuum suction pump 12, primary filter adsorption suspension conduit structure 13, detachable Suspension mixing rod structure 14, separated liquid odor emission anti-pollution treatment core structure 15 and separated liquid deep adsorption treatment anti-pollution pipe structure 16, the four corners of the bottom of the frame 1 are respectively connected with supporting legs by longitudinal bolts 2. The upper bolt of the frame 1 is connected to the inverted U-shaped bracket 3; the lower left side screw of the inverted U-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com