Sheet metal welding fixture

A welding fixture and sheet metal technology, applied in the field of sheet metal welding fixtures, can solve the problems of increased time cost, labor cost, increased economic cost of sheet metal parts, and waste of time, so as to reduce labor cost and economic cost , Adjust the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

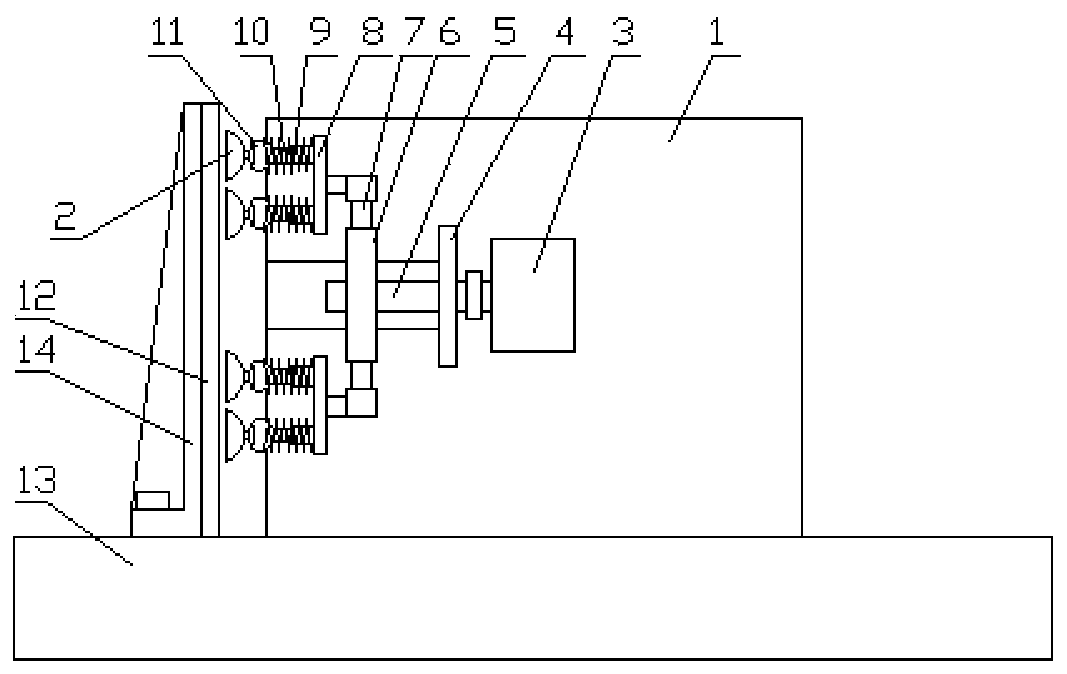

[0034] Such as figure 1 and figure 2 As shown, a kind of sheet metal welding fixture provided by the present invention comprises:

[0035] Workbench 13 used as integral support;

[0036] Bending plate 14 is pressed on the table top of the workbench 13 by a pressing plate or a T-bolt;

[0037] Bending plate two 1 is pressed on the table top of the workbench 13 by a pressing plate or a T-bolt, and the working surface of bending plate two 1 is perpendicular to the working surface of bending plate one 14;

[0038] The support 4 is connected to the working surface of the bent plate 2 1 by bolts;

[0039] The motor 3 is connected to the working surface of the bent plate 1 by bolts, and the output shaft of the motor 3 is arranged on the side close to the bent plate 14;

[0040] Screw 5, one end of which is connected to the output shaft of motor 3 through a coupling, and the other end is erected on the support 4 through a bearing;

[0041] The nut seat 6 is arranged on the end o...

Embodiment 2

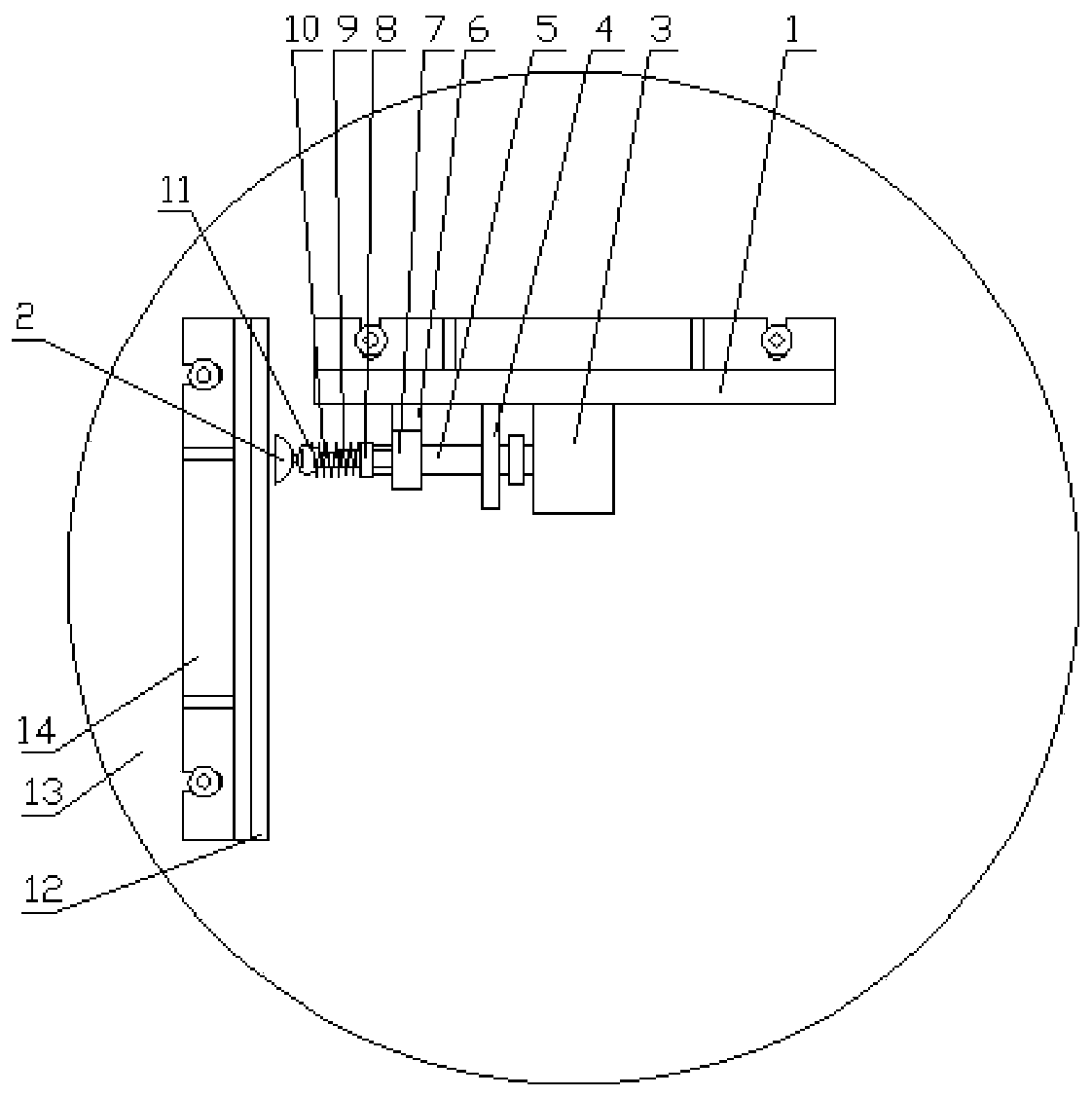

[0049] In order to further expand the scope of application of the clamp, telescopic rods 7 for extending the range of action of the clamp are respectively provided at both ends of the nut seat 6, and the setting of the two telescopic rods makes the range of action of the pressure block 2 larger.

[0050] One end of the telescopic rod 7 away from the nut seat 6 is fixedly connected to the strut, the center line of the strut is perpendicular to the center line of the telescopic rod 7, and the end of the strut away from the telescopic rod 7 is vertically fixed to the plate body 8, and the plate body 8 is provided with at least one Rod body 10.

[0051] Further, the telescopic rod 7 includes a sleeve 2 and an inner rod body 2, one end of the sleeve 2 is fixed to the nut seat 6, one end of the inner rod body 2 is inserted into the sleeve 2, and the other end is fixed to the strut, A fastening screw for fastening the position of the inner rod body two is arranged on the sleeve two. ...

Embodiment 3

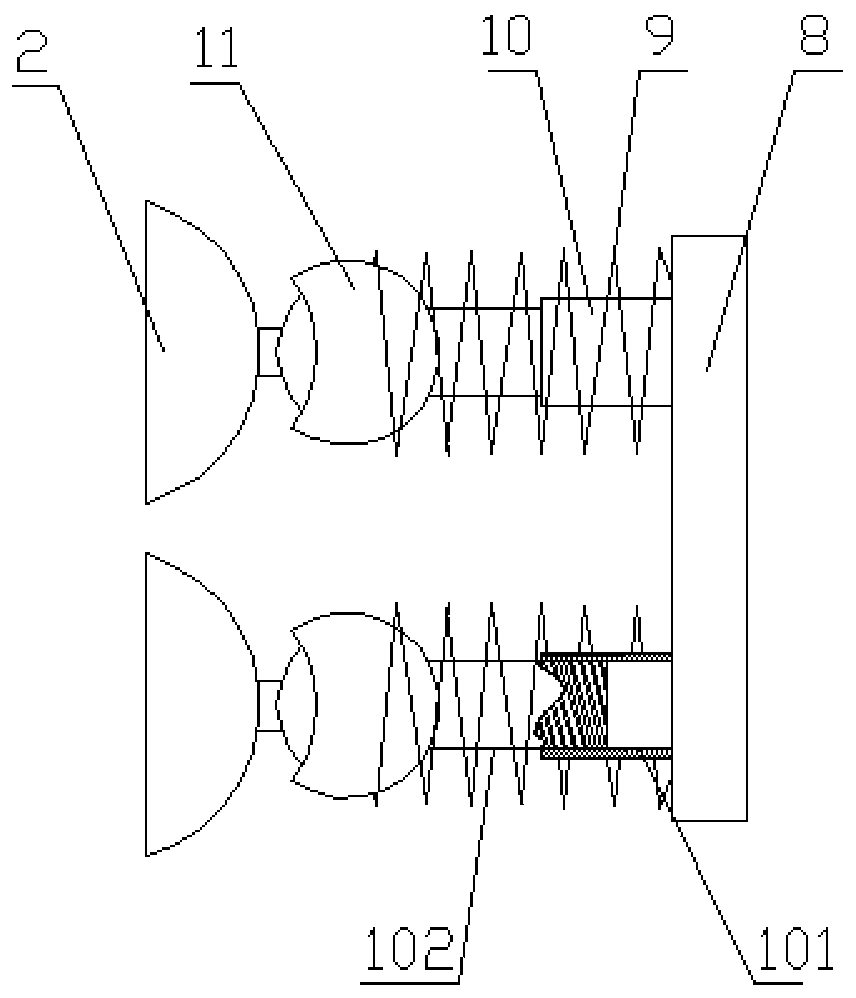

[0054] In order to further adapt to the shape changes of sheet metal parts, such as image 3 As shown, the rod body 10 is set to a structure whose length can be adjusted adaptively. The specific structure is that the rod body 10 includes a sleeve one 101 and an inner rod body one 102, one end of the sleeve one 101 is vertically fixed to the plate body 8, and the inner rod body One end of one 102 is inserted into the sleeve one 101, the other end is fixed with the ball head housing 11, and the sleeve one 101 is covered with a spring 9, one end of the spring 9 is in contact with the plate body 8, and the other end is connected with the ball head housing 11 butt.

[0055] The spring 9 is preferably a hard spring, which can not only meet the needs of clamping, but also adapt to changes in the shape of the sheet metal within a certain range.

[0056] In use, the plug-in structure of the inner rod body 102 and the sleeve 101 enables the coincidence of the two to be adjusted to a ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com