Industrial gas pipeline welding device

A technology of industrial gas and welding equipment, applied in auxiliary equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of danger and poor welding effect, and achieve the advantages of welding, welding accuracy, and better and labor-saving feeding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

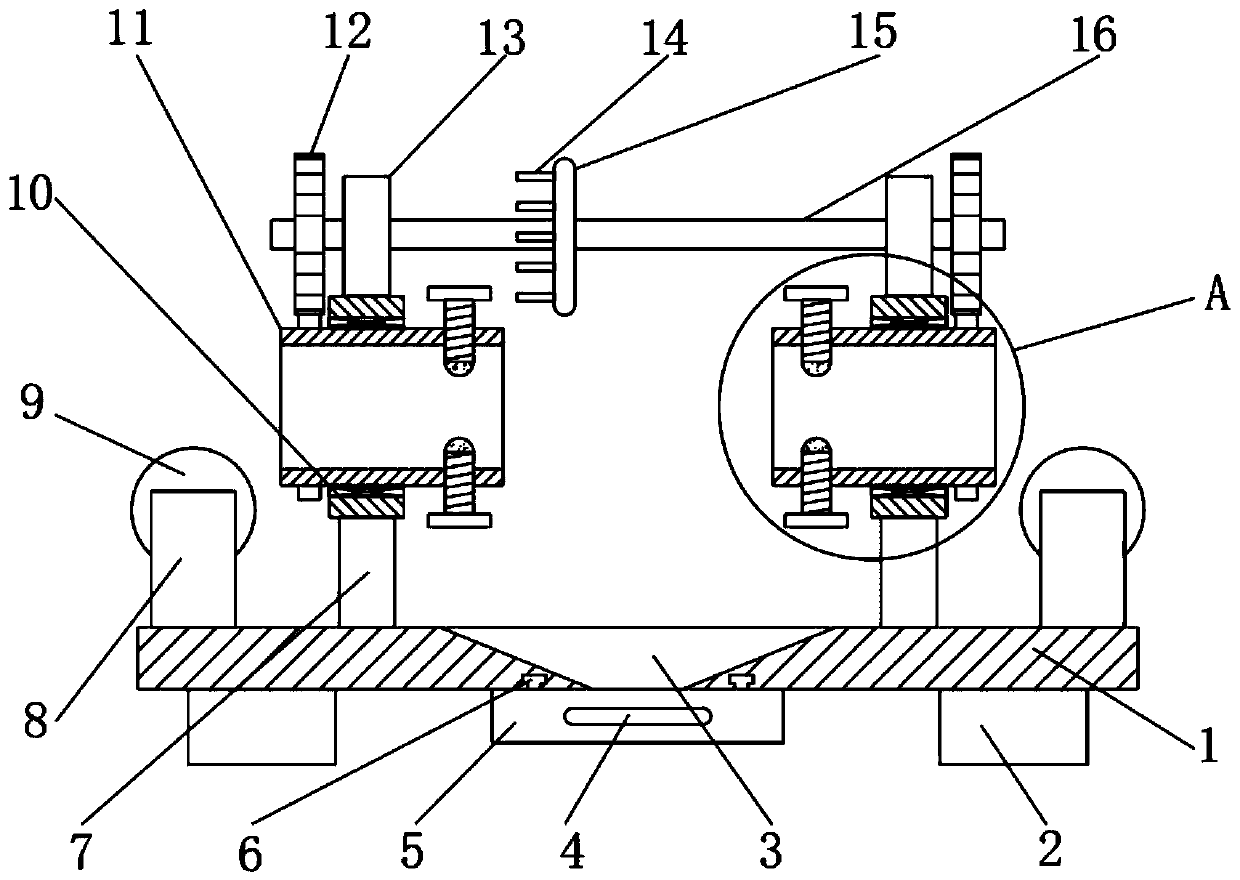

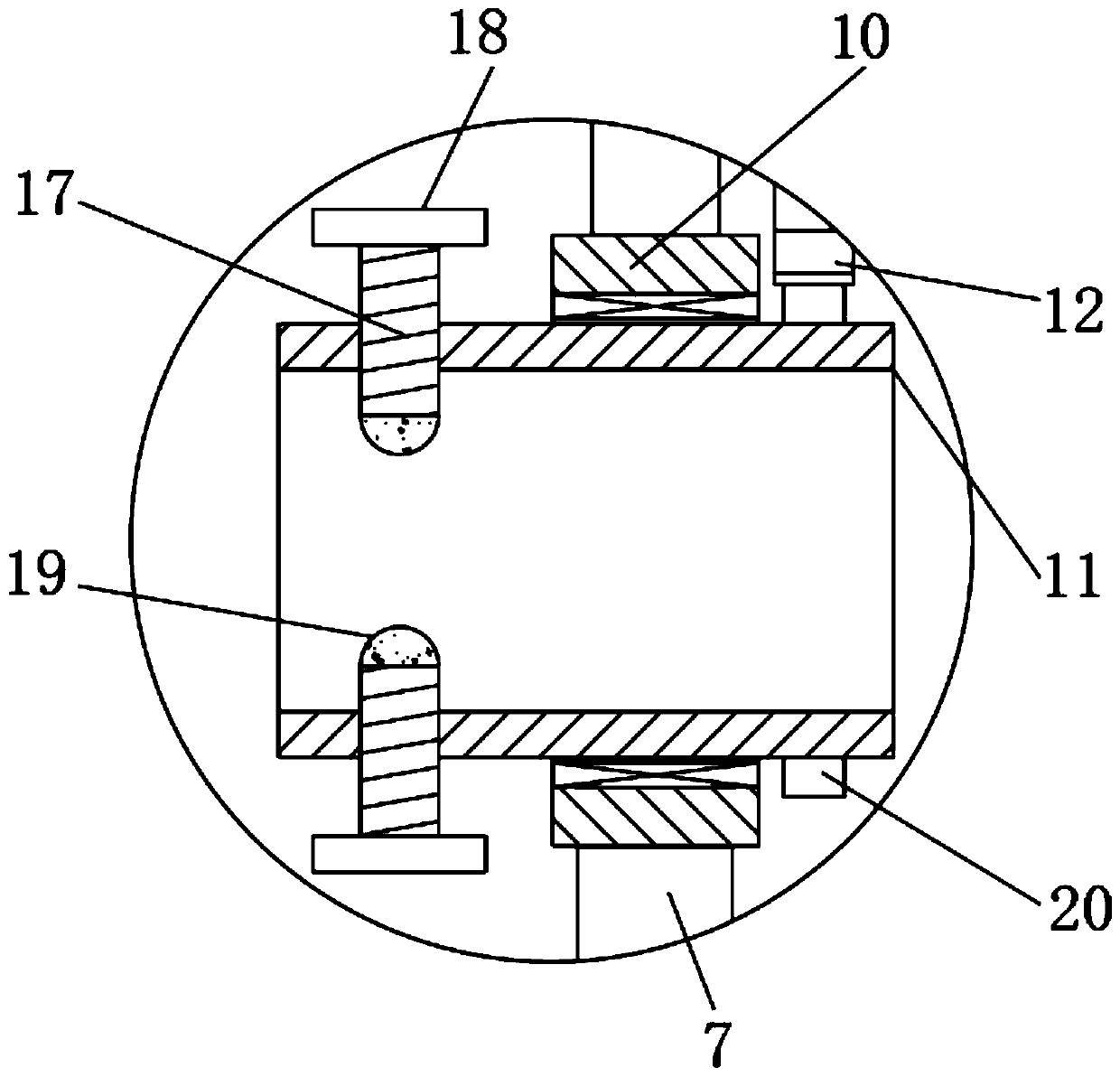

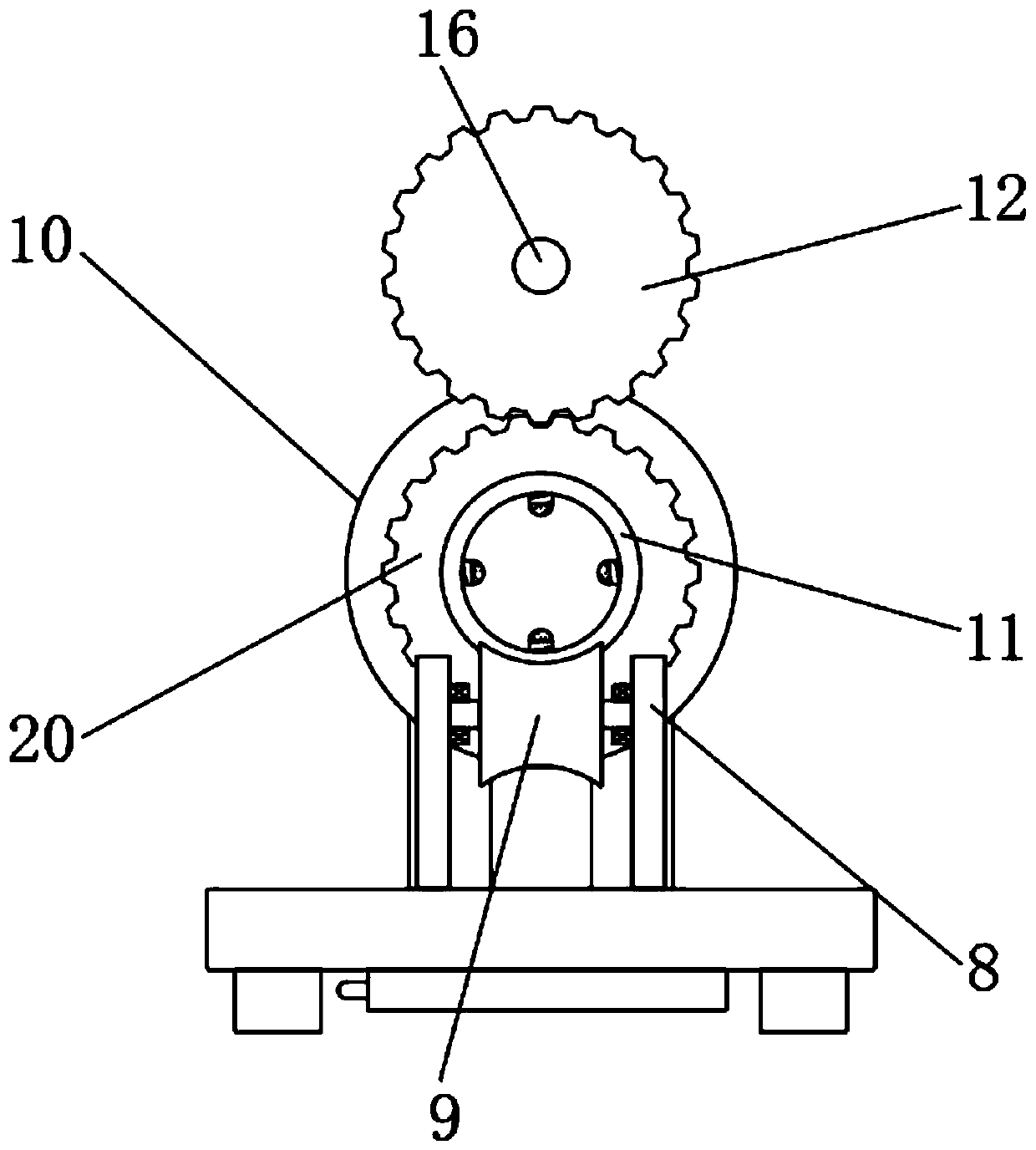

[0032] refer to Figure 1-4 , an industrial gas pipeline welding device, including a base plate 1, a cylinder 10 and a fixed cylinder 11, support blocks 2 are evenly welded at the four corners of the bottom outer wall of the base plate 1, and upright columns are welded on the top outer wall of the base plate 1 near both sides 7, and the top outer wall of the column 7 is welded to the bottom outer wall of the cylinder 10, the inner wall of the cylinder 10 and the outer wall of the fixed cylinder 11 are rotatably connected by bearings, and the outer wall of the fixed cylinder 11 is provided with threaded holes that are equidistant and annularly distributed, and The inner wall of the threaded hole is threadedly connected with a stud 17, the top of the stud 17 is welded with an adjustment wheel 18, the top outer wall of the fixed cylinder 11 is welded with a riser 13, and one side outer wall of the riser 13 has a concave hole, the concave hole The inner wall is rotatably connected...

Embodiment 2

[0036] refer to Figure 5 , an industrial gas pipeline welding device. Compared with Embodiment 1, this embodiment also includes a fixed rod 21 welded on the top outer wall of the bottom plate 1, and a shaped hose 22 is welded on the top outer wall of the fixed rod 21. The shaped hose 22 A goggle is welded on the outer wall of one end of the goggle, and one side of the goggle is provided with an installation opening, and the inner wall of the installation opening is connected with goggles 23 by fastening bolts.

[0037] Working principle: During the welding process, the shape of the shaped hose 22 can be changed at will, so that the goggles 23 on the shaped hose 22 can be placed in front of the worker, which protects the eyes and effectively improves the safety performance of the device during use .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com