Active thrust balance type shafting longitudinal vibration reduction device

A thrust balance and vibration damping device technology, which is applied in the transmission device, shock absorber, liquid shock absorber, etc. of synchronous propulsion components, can solve the problems of limiting the low frequency vibration isolation control range and use effect of the propeller shaft system, and achieves The effect of preventing equipment overload damage and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

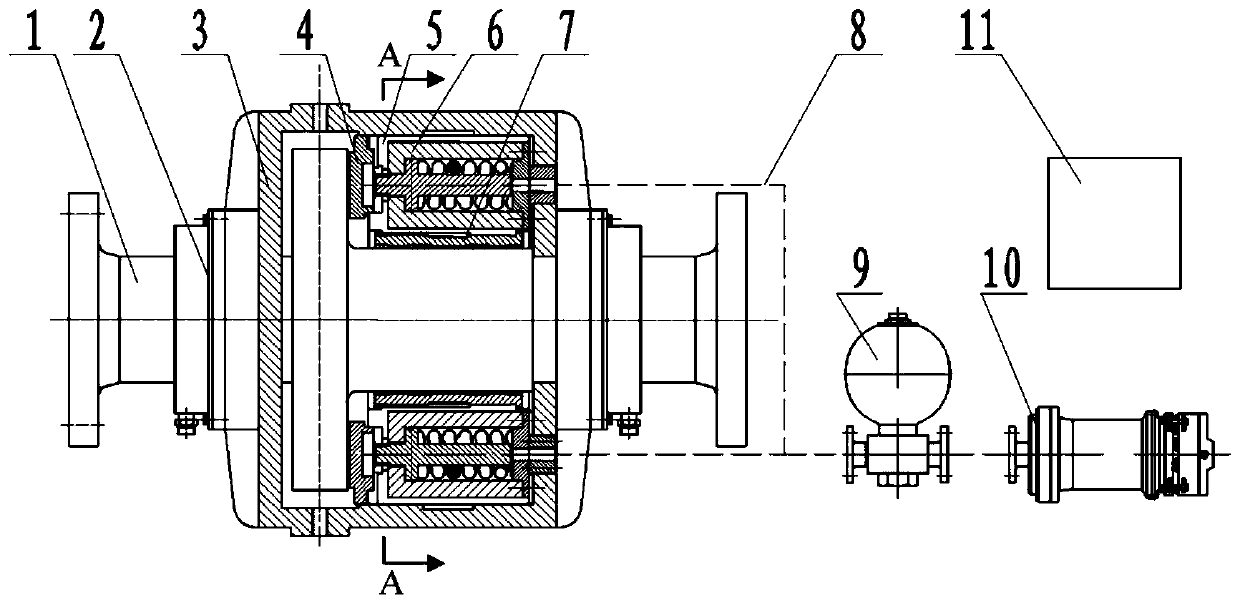

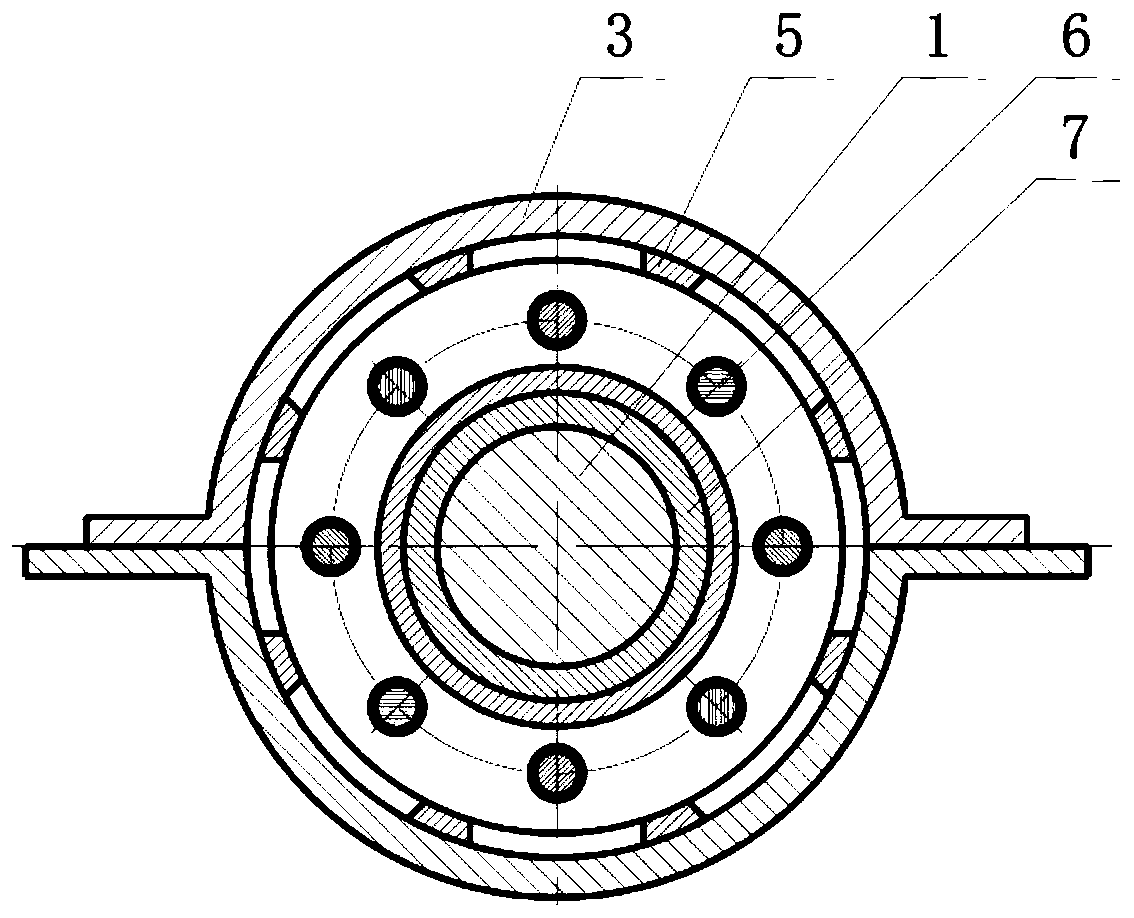

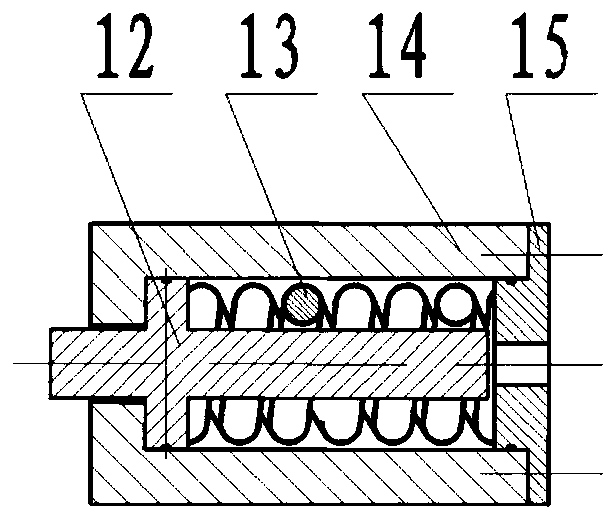

[0024] Such as figure 1 , 2 As shown, this embodiment provides an active thrust balance type shafting longitudinal vibration damping device, which includes a housing 3 that is sleeved on the thrust shaft 1 and sealed with the thrust shaft 1, and a thrust block installed in the housing 3 4. The longitudinal vibration damping structure arranged opposite to the thrust block 4, the hydraulic pipeline 8 arranged with the vibration damping structure, the servo hydraulic machine 10, and the thrust detection control module 11. A supporting collar 5 is sheathed on the thrust shaft 1, and the supporting collar 5 is set on the thrust shaft 1 through the supporting bearing bush 7. The thrust block is an arc-shaped block structure, and the thrust block is eight or six block, which are evenly distributed in the circumferential direction of the shaft shoulder end, the front end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com