Three-dimensional temperature measurement wireless sensor for power cable joint

A wireless sensor and power cable technology, applied to thermometers, instruments, thermometers, etc. that use electric/magnetic components that are directly sensitive to heat, can solve the difficulty of laying optical fibers, the heavy workload of optical fiber installation and operation and maintenance, and dense urban cables Problems such as distribution and branch inapplicability, to achieve the effect of ensuring accuracy and solving positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

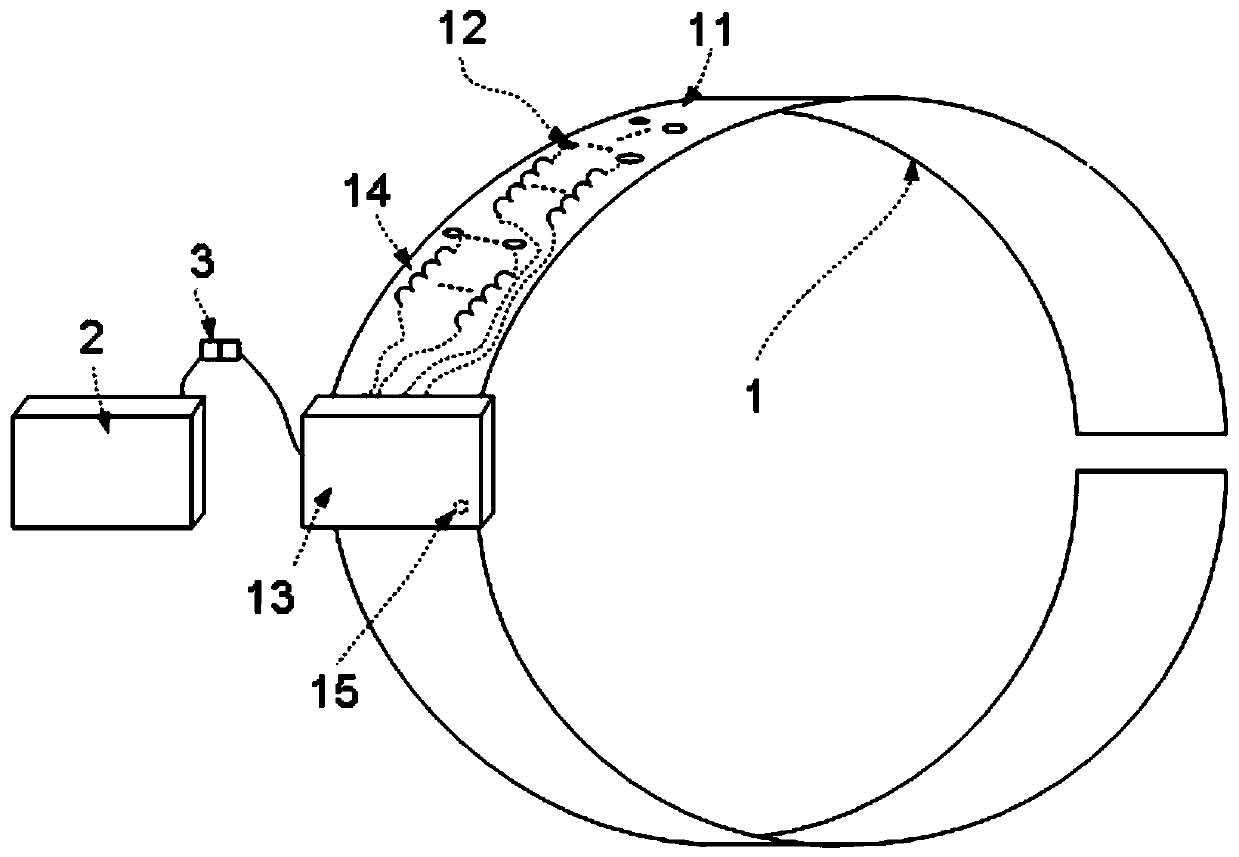

[0024] see figure 1 , a wireless sensor for three-dimensional temperature measurement of a power cable joint of the present invention includes a three-dimensional temperature measurement strap 1 and a battery compartment 2, the three-dimensional temperature measurement strap includes an elastic plastic annular belt 11, different types of temperature measurement probe sensors 12 and electronic Bin 13. The electronic compartment 13 is connected to the battery compartment 2 through a pluggable waterproof connector 3 . The battery compartment 2 is set away from the three-dimensional temperature measurement strap 1. On the one hand, it can avoid the heat and microwaves of the battery components from interfering with the temperature measurement. Strap 1 Higher freedom of setting.

[0025] Elastic plastic ring-shaped belts 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com