Thin film magnetic sensor with groove structure

A magnetic sensor and thin film technology, applied in the field of sensors, can solve the problems of size and change degree limitation, adjustment of particle type or content of each component, reduction of sensitivity of magnetic film, etc., to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

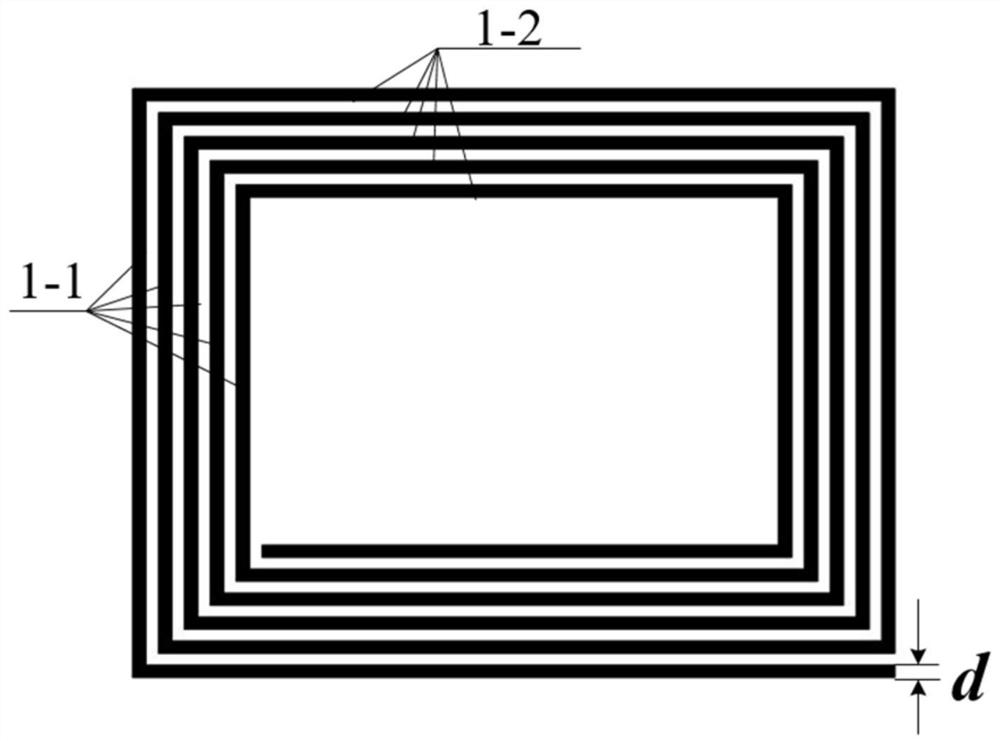

[0045] Such as image 3 Schematic diagram of the structure of the rectangular spiral coil;

[0046] The rectangular spiral coil 1 has a rectangular planar spiral structure as a whole, and the wires in the two vertical directions are composed of a conductor, and the width of each conductor is d;

[0047] The corners of the rectangular spiral coil 1 are vertically connected by a conductor 1 - 2 parallel to the long side direction of the magnetic film 2 and a conductor 1 - 1 in the short side direction.

[0048] The conductors constituting the rectangular spiral coil 1 are divided into two parts: a conductor 1-1 parallel to the short-side direction of the magnetic film 2 and a conductor 1-2 in the long-side direction. If the magnetic field to be measured is applied along the direction of the long side of the magnetic film 2, the conductor 1-1 perpendicular to the direction of the magnetic field to be measured on the coil 1 can cause a sensing response in the direction of the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com