Analysis method and analysis apparatus for urea

An analysis method and technology of analysis equipment, applied in the field of urea analysis and analysis equipment, can solve problems such as poor sensitivity of urea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

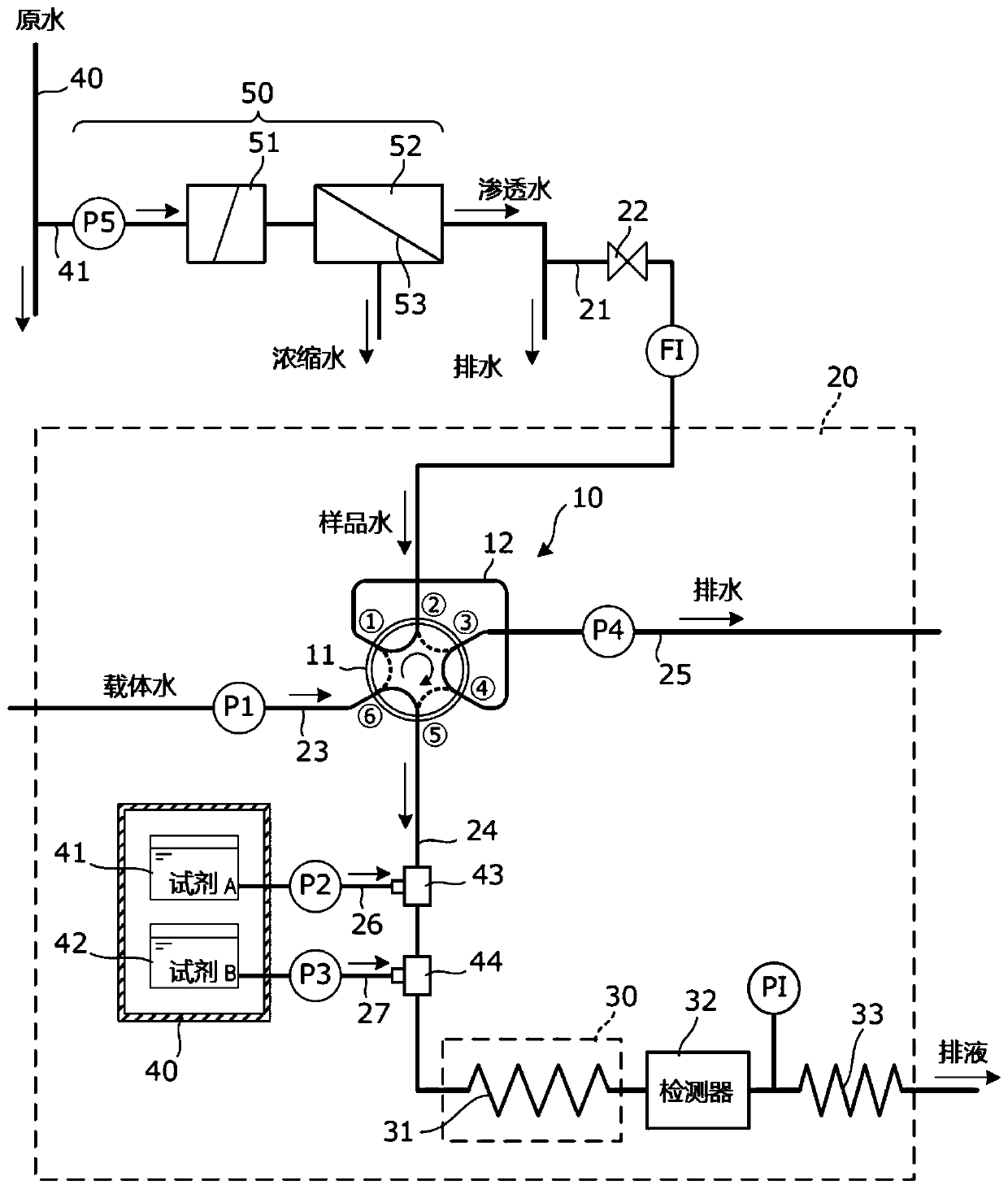

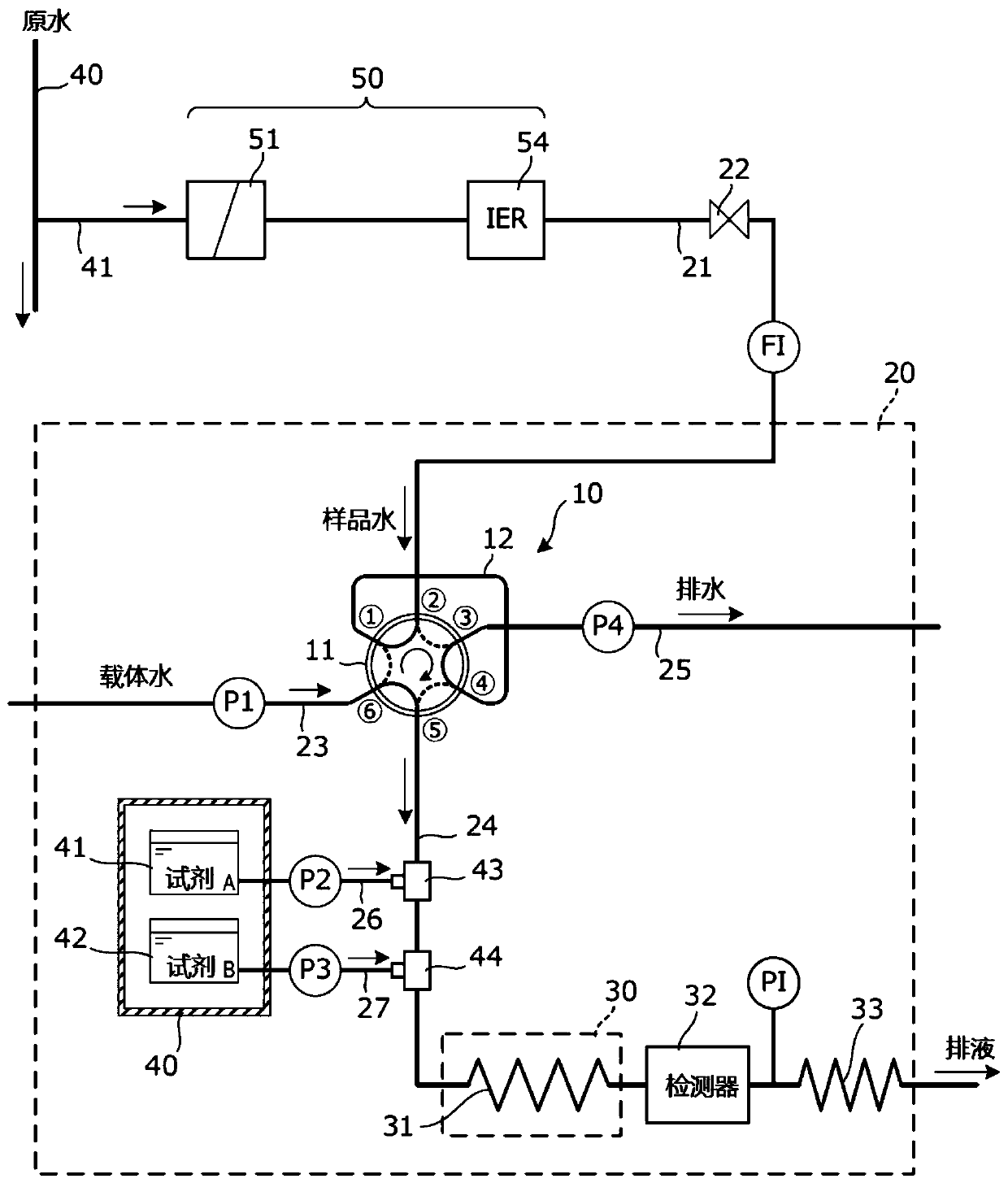

[0052] In Example 1, it was shown that by passing sample water through a reverse osmosis membrane device as pretreatment, interfering substances can be removed at the time of quantification of urea.

[0053] exist figure 1 In the analysis device shown, a preprocessing unit 50 and an analysis unit 20 are equipped. However, the preprocessing unit 50 is not provided with the filter 51 . In the membrane device 52 , as the membrane 53 , a reverse osmosis membrane TW30-1812 manufactured by Dow Corporation with a desalination rate of 98% was used. Raw water used in factory A was used as sample water 1, this sample water 1 was supplied to sampling valve 10 of analysis unit 20, and the urea concentration was measured by analysis unit 20, then its value was used as urea detection concentration. In addition, the sample water obtained by passing the sample water 1 through the pretreatment unit 50 is referred to as RO treated water, and a part of the RO treated water is separated and sup...

Embodiment 2

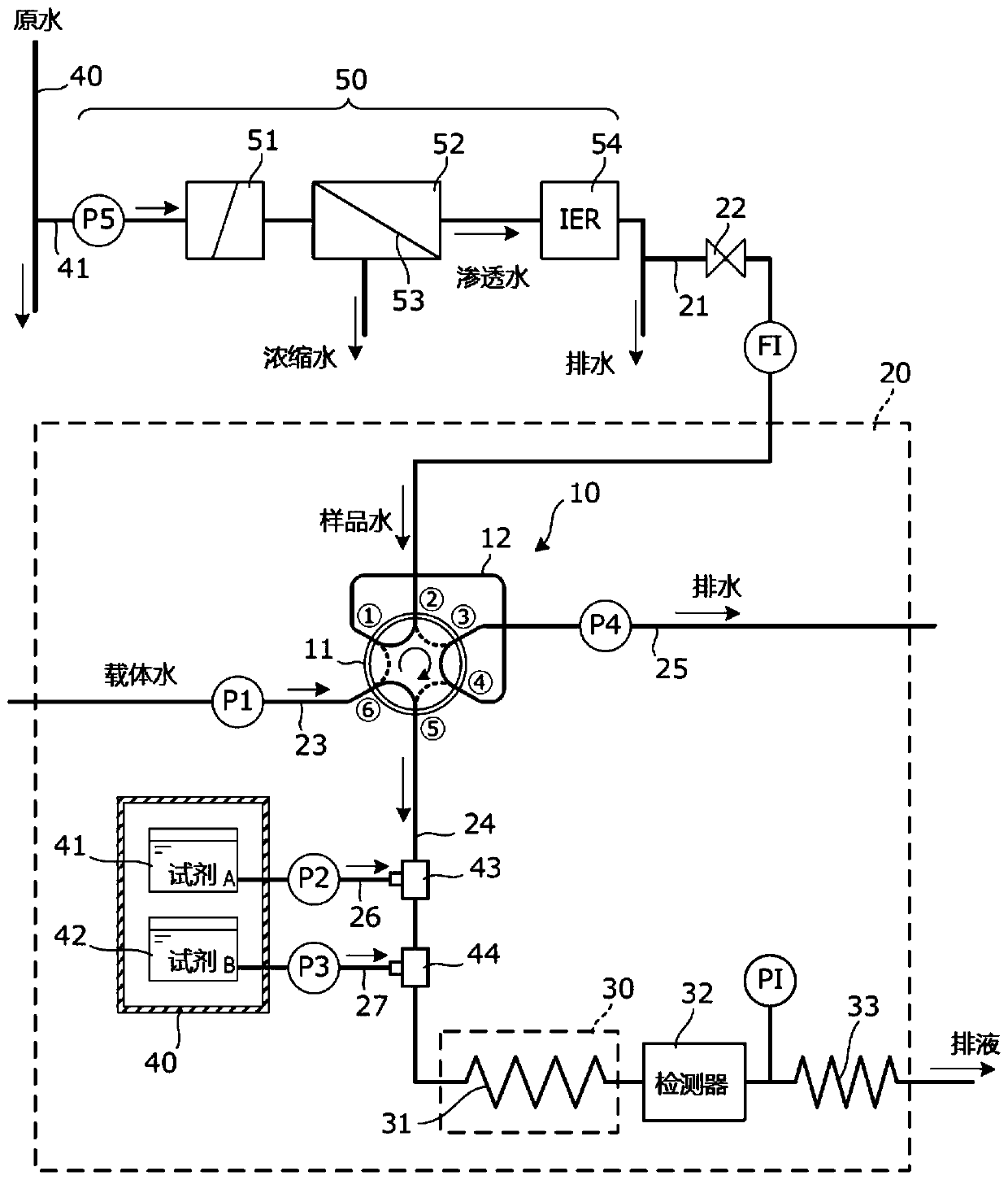

[0062] When the type of the membrane 53 in the membrane device 52 was changed, the urea removal rate was measured. As the membrane 53 installed in the membrane device 52 of the facility in Example 1, a reverse osmosis membrane XLE-440 manufactured by Dow Corporation with a desalination rate of 99% was used. Prepare a urea standard solution so that the urea concentration is 50ppb, and in the same manner as in Example 1, the supply pressure of the membrane device 52 is 0.33MPa, the water supply is 1130L / hour, and the permeated water is 200 liters / hour. Measure urea removal rate. At this time, the water recovery rate in the membrane device 52 was 18%. The removal rate of urea is 20%.

Embodiment 3

[0064] As the membrane 53 installed in the membrane unit 52 of the facility in Example 1, a reverse osmosis membrane ES20 manufactured by Nitto Denko Co., Ltd. with a desalination rate of 99.7% was used. A urea standard solution was prepared so that the urea concentration was 50ppb, and the urea removal rate was measured in the same manner as in Example 1, wherein the supply pressure of the membrane device 52 was 0.42MPa, the water supply rate was 6700 liters / hour, and the permeated water volume was 1000 liters / hour. At this time, the water recovery rate in the membrane device 52 was 15%. The removal rate of urea was 34%.

[0065] From the results of Examples 1-3, the higher the salt removal rate of the membrane 53 which is a reverse osmosis membrane, the higher the urea removal rate becomes. The real urea concentration in the sample water can be known by correcting the detection results of urea in the analysis unit 20 based on the urea removal rate, but when the urea remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com