Ubenimex recrystallization device and method thereof

A technology of ubimethoxine and recrystallization, applied in the field of medicine, can solve the problems of easily damaged agitator motor, inoperable agitator, affecting production efficiency, etc., and achieves the effects of increasing yield, easy production process and reducing dead space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

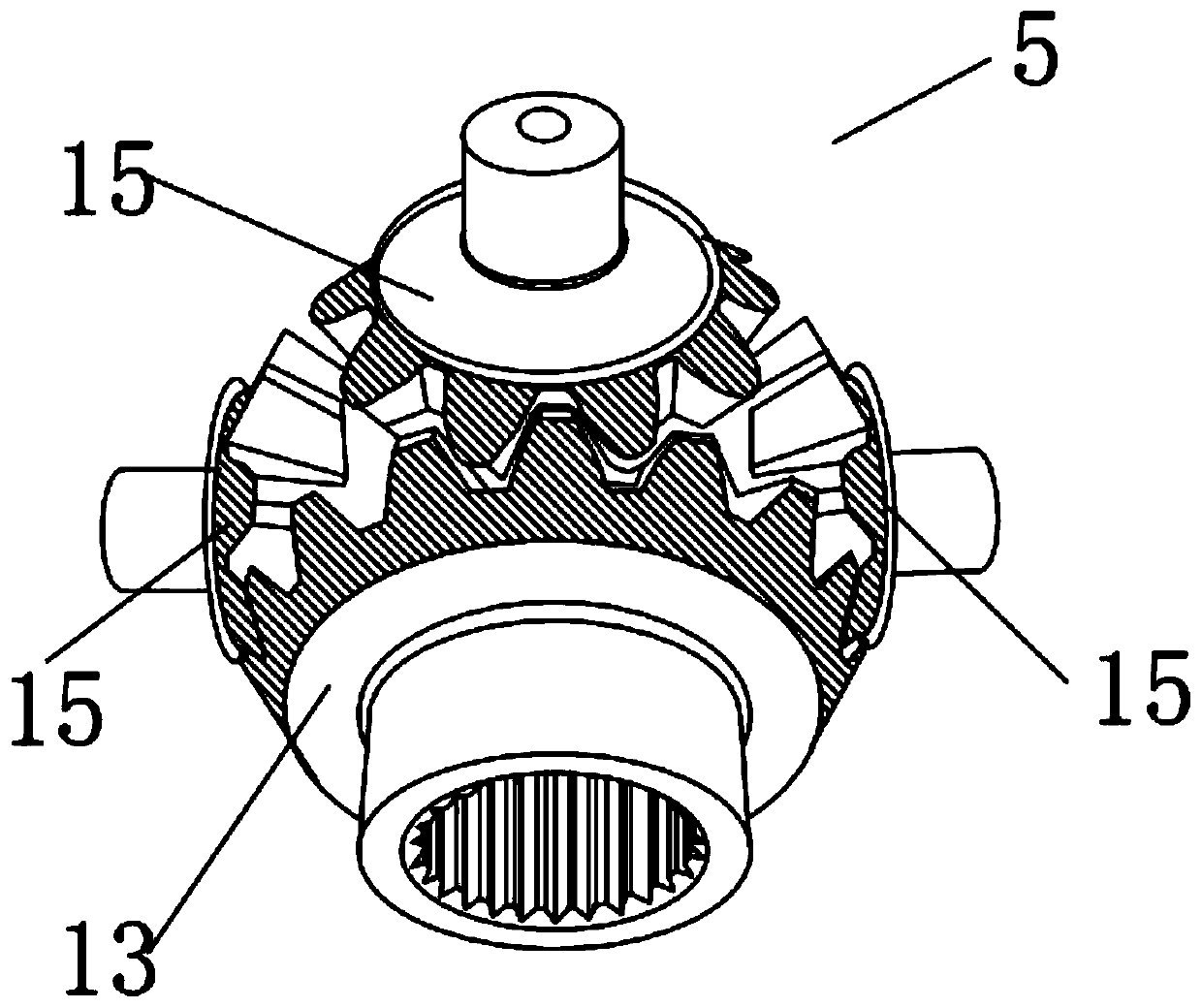

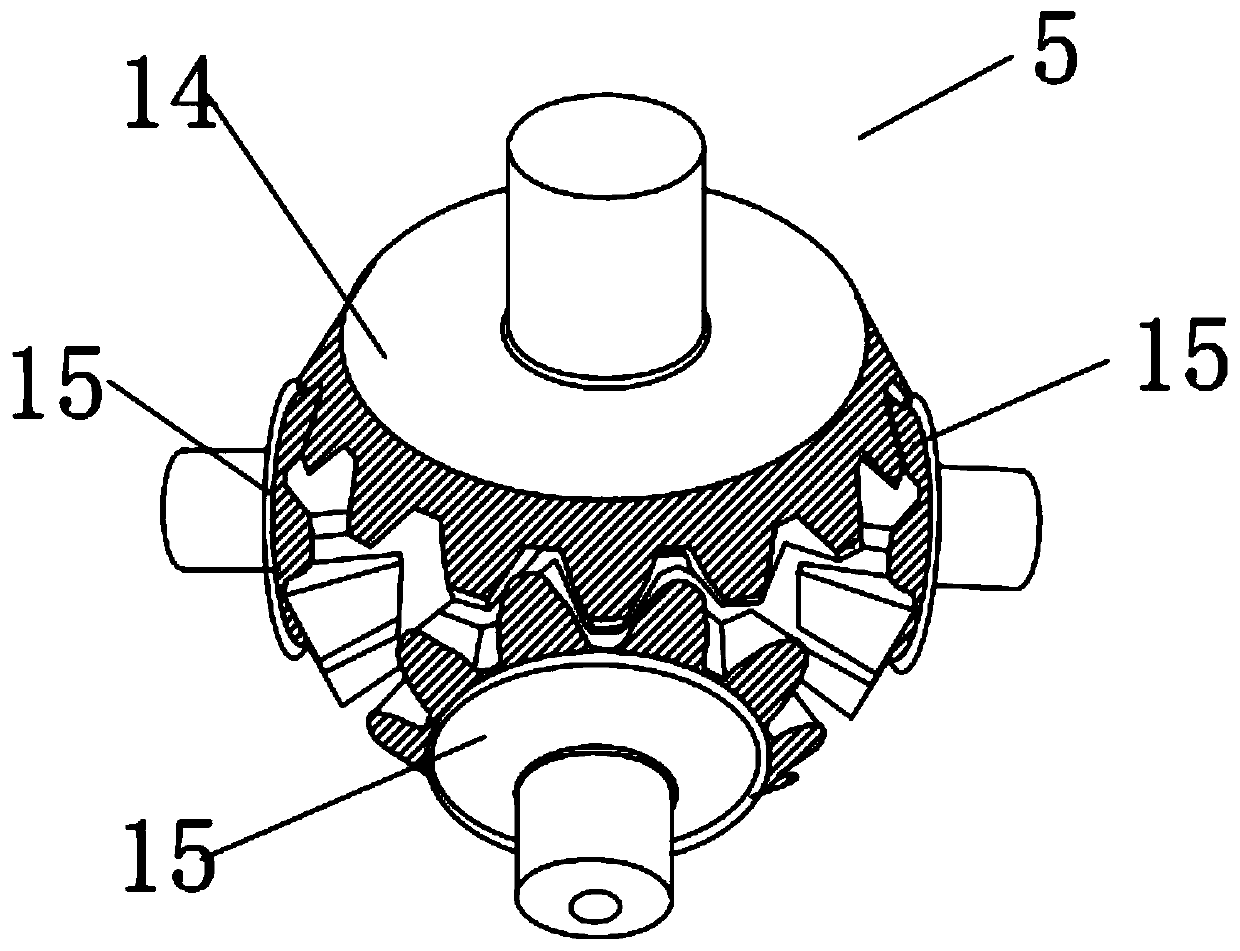

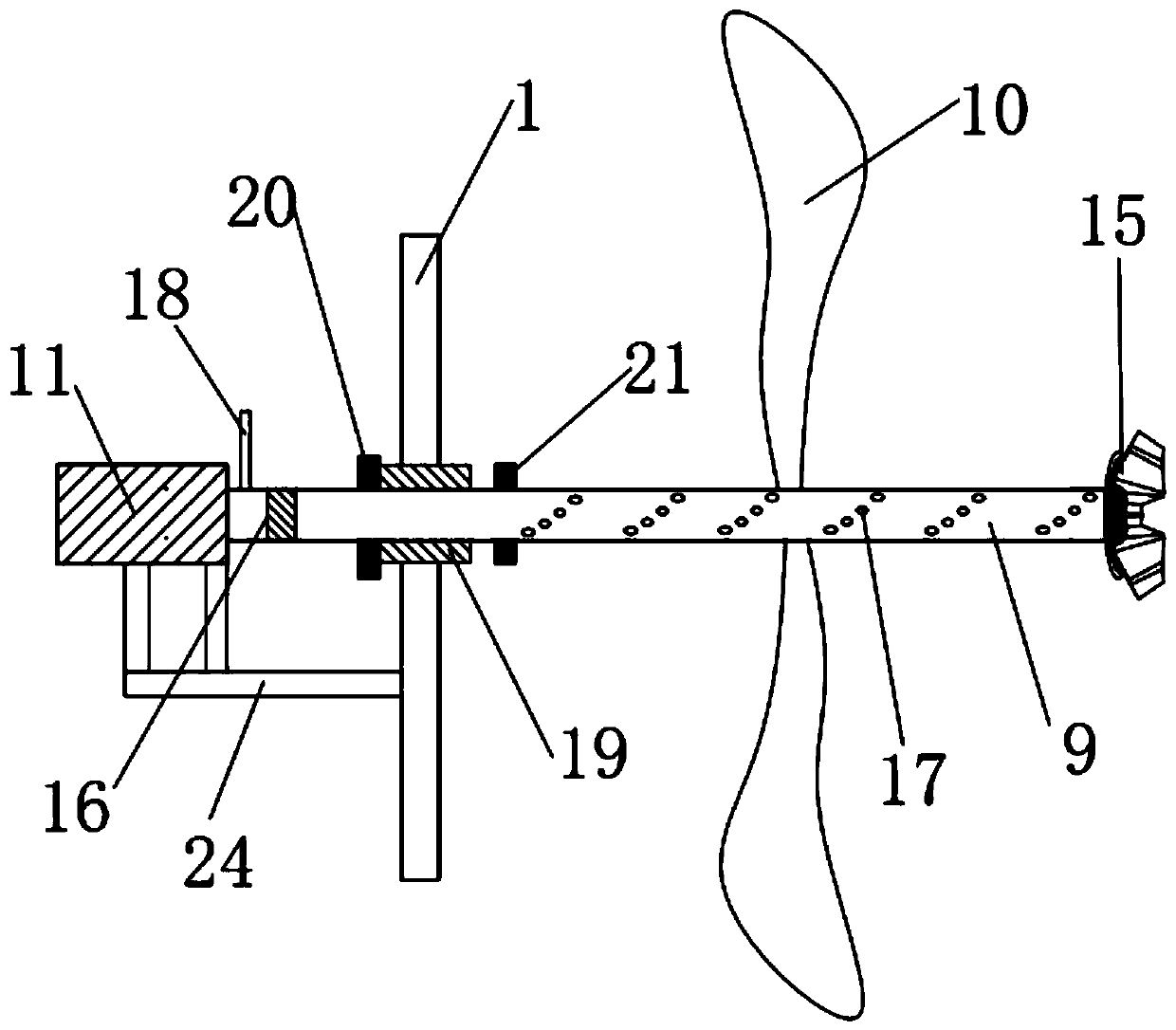

[0029] like Figure 1-2 As shown, this embodiment provides an Ubenimex recrystallization device, including a reaction kettle 1 and a driving motor 2 arranged at the bottom of the reaction kettle 1, and the driving motor 2 is connected to the main stirring shaft 3 through the main stirring shaft 3. The bevel gear transmission mechanism 5 in the reactor 1 is connected; wherein, the bevel gear transmission mechanism 5 is composed of a main planetary gear 13, at least one side planetary gear 15 and a slave planetary gear 14 arranged from bottom to top. The side planetary gears 15 are respectively gear-connected with the main planetary gear 13 and the slave planetary gear 14, the main planetary gear 13 is axially connected with the main st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com