Petroleum filtering equipment

A filter equipment and oil technology, which is applied in the direction of filtration separation, purification by filtration, mobile filter element filter, etc., can solve the problems of affecting the environment, oil loss, oil falling out, etc., and achieve the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

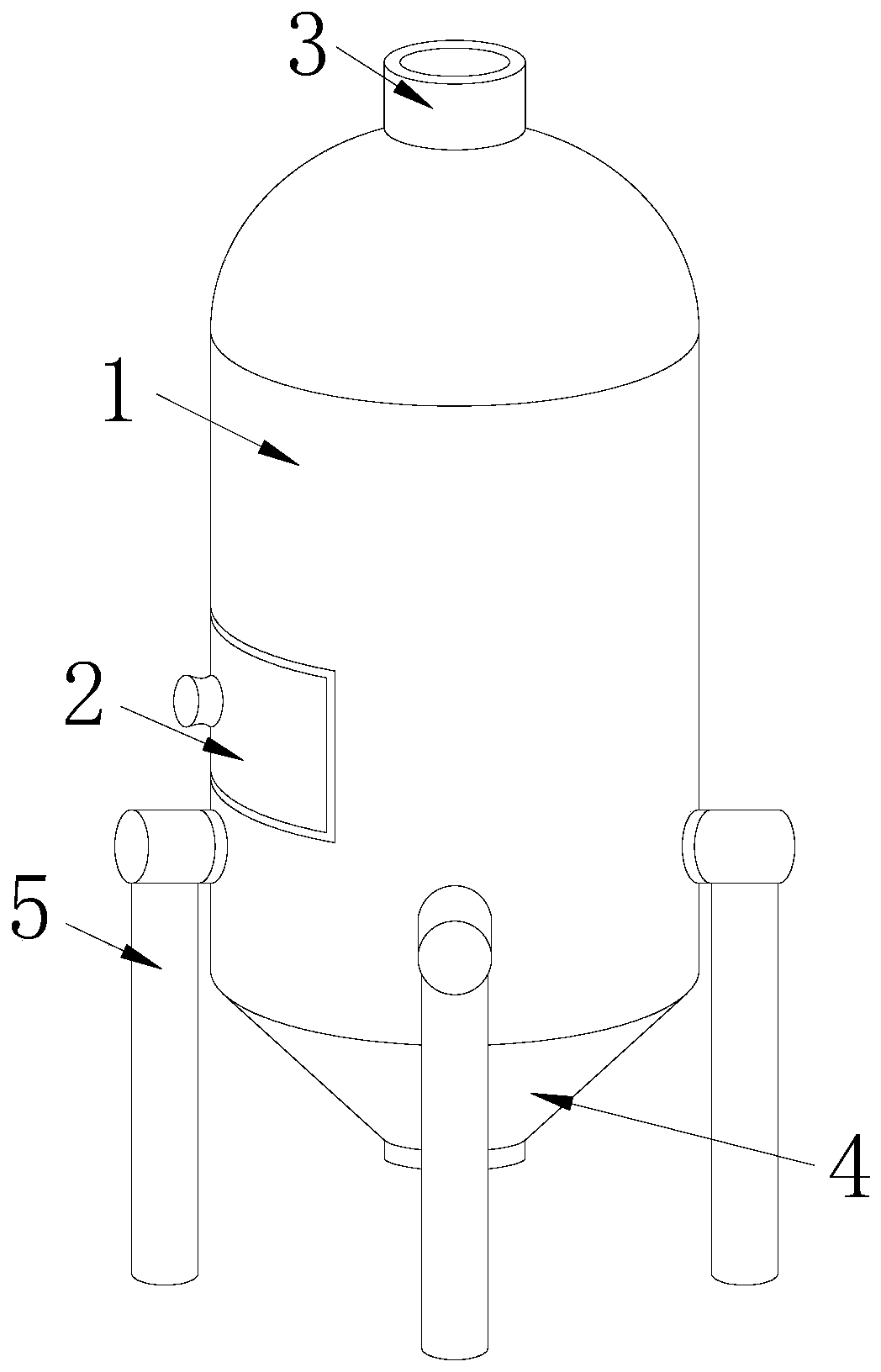

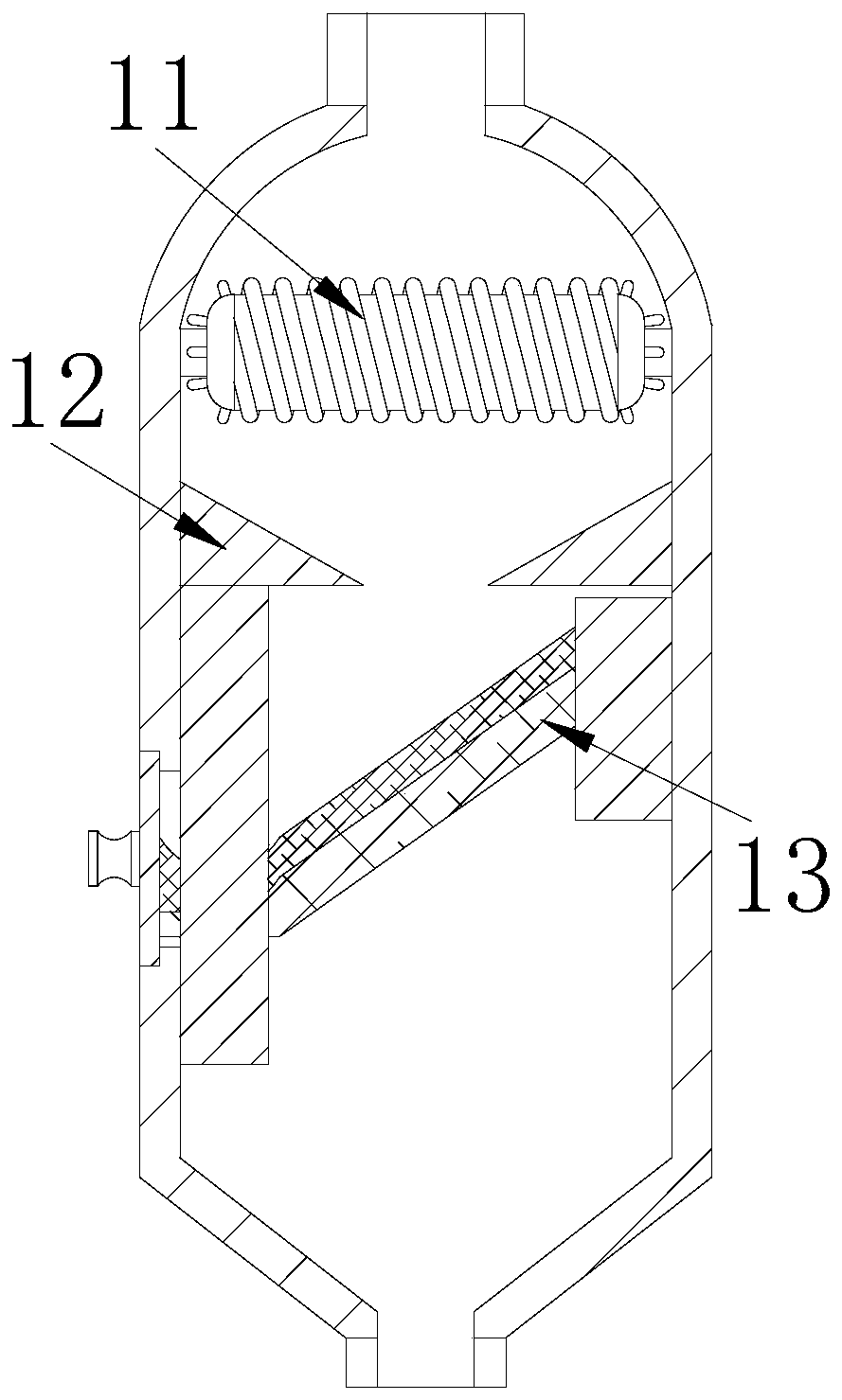

[0026] see Figure 1-Figure 4 :

[0027] A kind of oil filtration equipment, its structure includes filter cartridge 1, impurity removal device 2, crude oil inlet 3, oil discharge port 4, bracket 5, said filter cartridge 1 is installed above the bracket 5, and said impurity removal device 2 is installed on On one side of the filter cartridge 1 surface, the crude oil inlet 3 is connected to the top of the filter cartridge 1 by welding, the oil discharge port 4 is embedded in the bottom of the filter cartridge 1, there are four brackets 5, and the filter cartridge 1 includes a mill Pressing device 11, guide plate 12, filter screen 13, described rolling device 11 is installed inside filter cartridge 1 and is positioned at crude oil inlet 3 just below, described guide plate 12 is connected to the inner wall of filter cartridge 1 by welding, and described filter screen 13 runs through the inner wall of the filter cartridge 1 and is located below the guide plate 12. The guide plate...

Embodiment 2

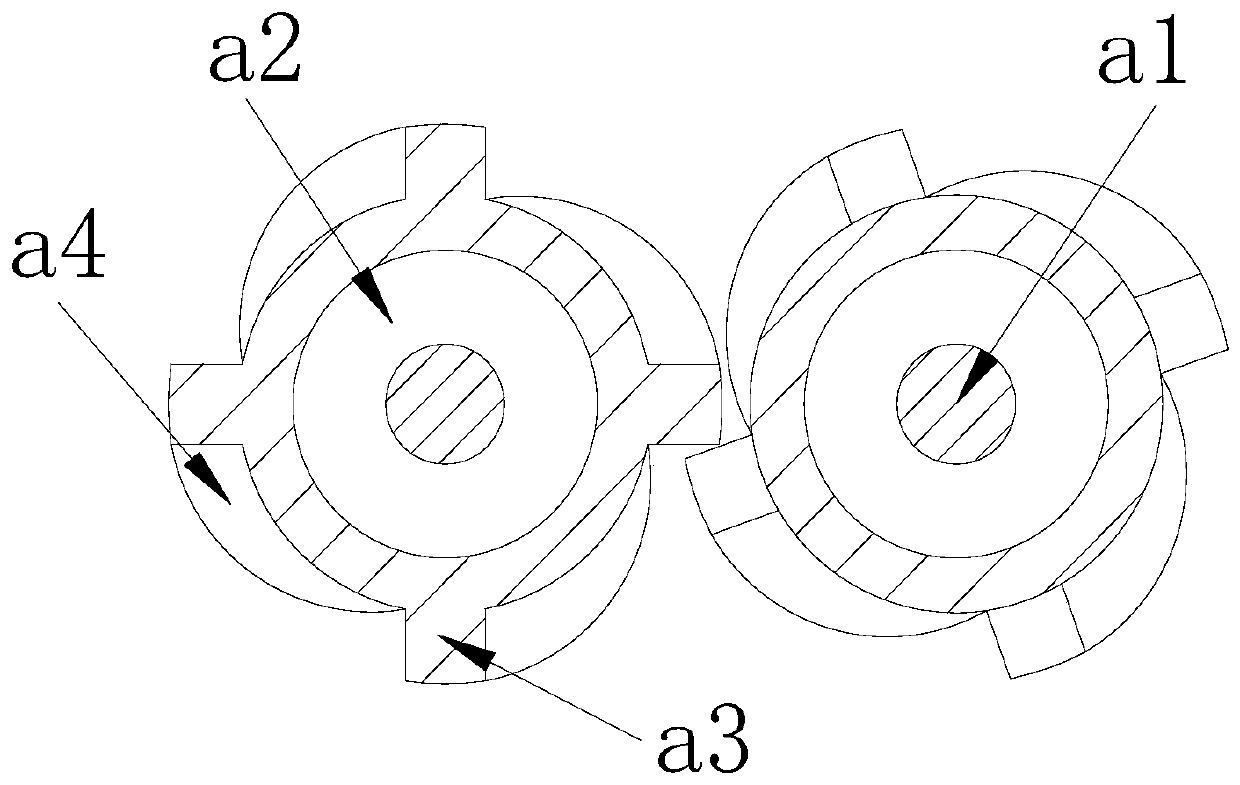

[0032] see Figure 5-Figure 6 :

[0033] In the figure, the filter screen 13 includes a fixed net 131 and a miscellaneous net 132. The fixed net 131 is connected to the bottom of the filter net 13 by welding, and the miscellaneous net 132 is connected to the upper surface of the fixed net 131 by movable engagement. The upper surface of the lower end of the miscellaneous net 132 is spoon-shaped, which is beneficial for storing filtered impurities.

[0034] In the figure, the two ends of the miscellaneous net 132 are respectively provided with a limiting device b1 and a cleaning device b2, the limiting device b1 is installed on the upper end of the miscellaneous net 132, and the cleaning device b2 is cooperatingly installed on the lower end of the miscellaneous net 132, The limiting device b1 and the cleaning device b2 are respectively embedded in the inner wall of the filter cartridge 1, and the surface is smooth and corrosion-resistant, so as to prevent crude oil from penetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com