A waste gas purification device

A waste gas purification device and waste liquid technology, applied in the direction of gas treatment, transportation and packaging, chemical instruments and methods, etc., can solve the problems affecting the treatment efficiency, air pollution, waste of resources, etc., to ensure the transmission efficiency, ensure the interception effect, Guaranteed cleansing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

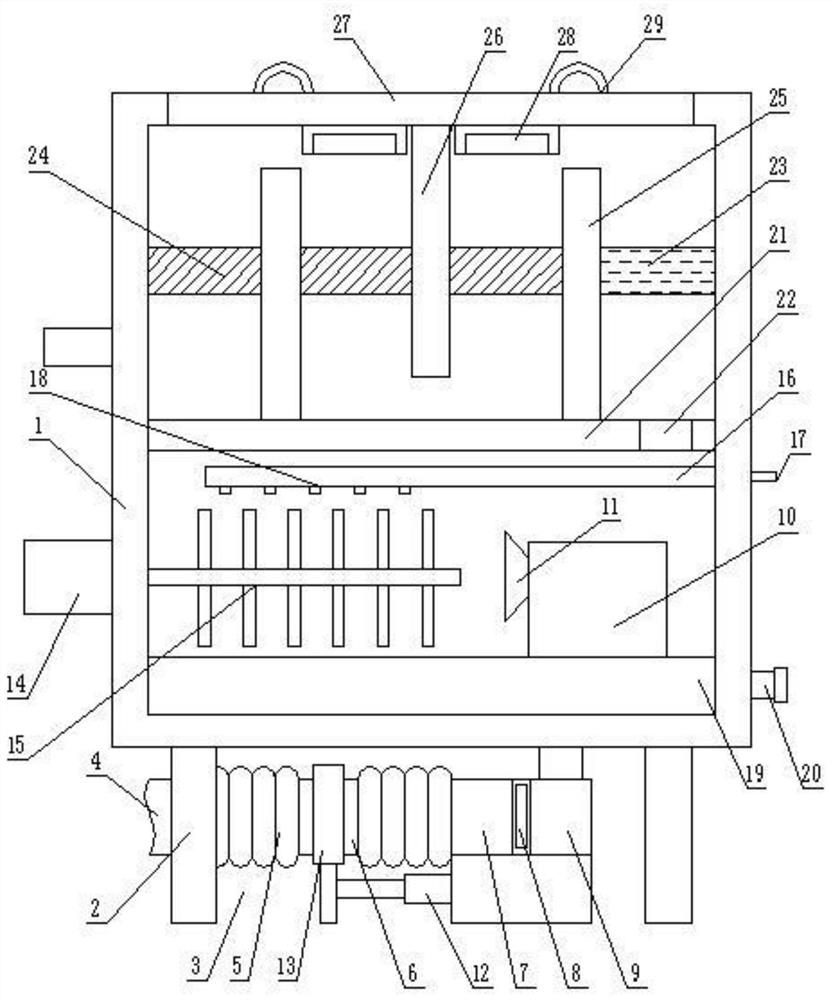

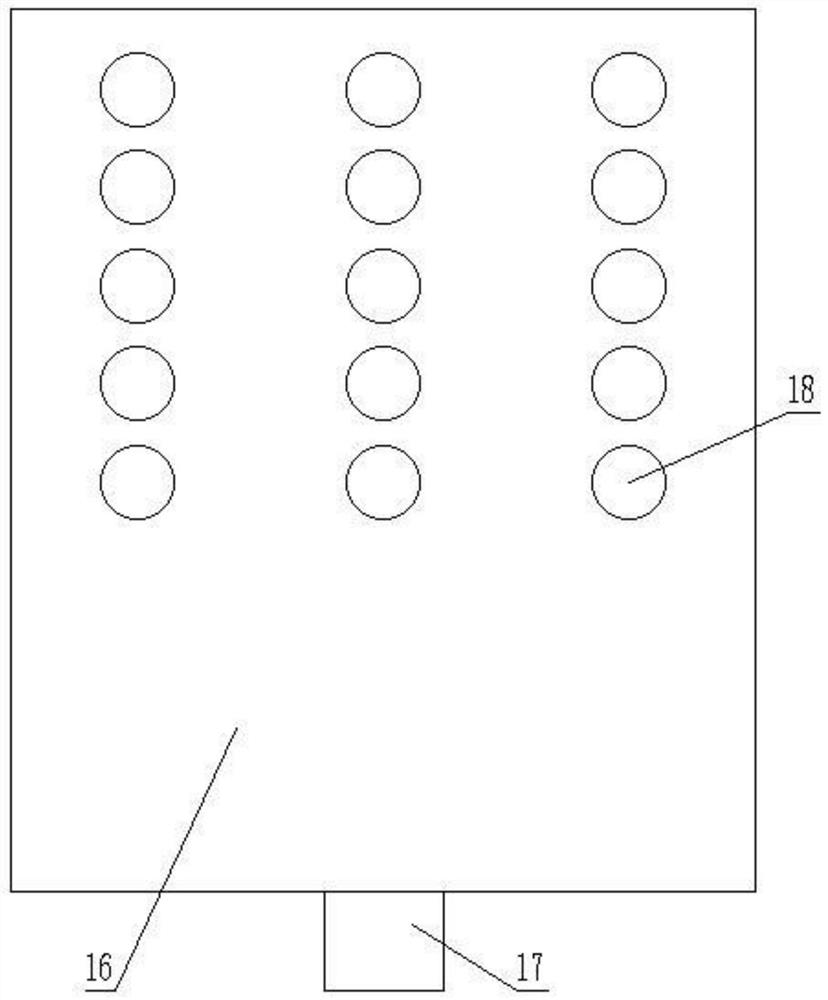

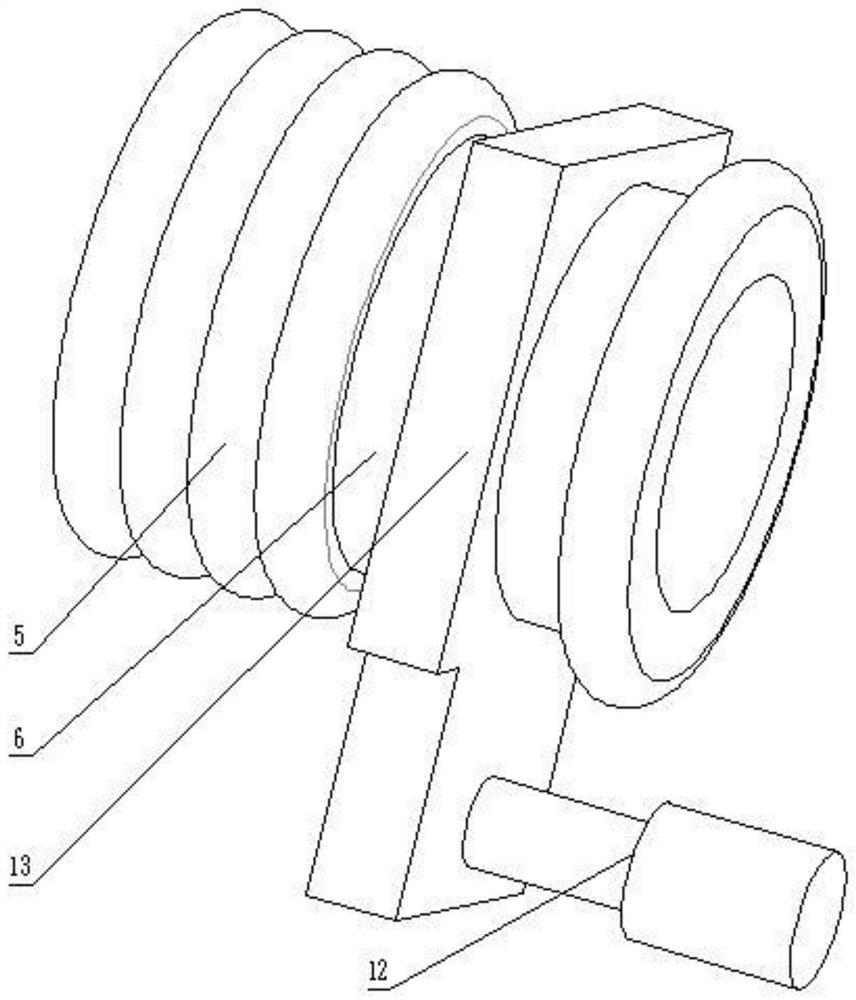

[0019] see Figure 1-3 , an exhaust gas purification device, including a box body 1 and a conveying structure 3, the bottom of the box body 1 is provided with a support leg 2, the conveying structure 3 is located at the bottom of the box body 1 and communicated with the inside of the box body 1, and the conveying structure 3 is used for The waste gas is transported into the box body 1, and the waste gas is preliminarily filtered during the transport. The upper part of the side of the box body 1 is provided with an exhaust pipe. The transport structure 3 includes an input connection pipe 4, a first one-way valve pipe 6 and The second one-way valve tube 7, the two of the first one-way valve tube 6 are connected with the expansion tube 5, the input connection tube 4 and the second one-way valve tube 7 are located on both sides of the first one-way valve tube 6 And all are sealed and docked with the expansion pipe 5, the interception pipe 8 and the fixed transfer pipe 9 are connec...

Embodiment 2

[0024] On the basis of Embodiment 1, the top of the box cover 27 is provided with an ultraviolet lamp 28, and the ultraviolet lamp 28 is located on both sides of the movable vertical plate 26, which is used to generate ozone in the box body 1 when the exhaust gas is purified. Existing bacteria are killed to ensure the comprehensive killing of organic and inorganic harmful gases.

Embodiment 3

[0026]On the basis of Embodiment 1, a rubber sealing strip is provided on the side of the box cover 27 to ensure the sealing effect inside the box body 1 during exhaust gas purification treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com