Preparation method of composite photocatalyst Ag/AgCl@Co3O4 and composite photocatalyst prepared by using preparation method

A composite light and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, cobalt oxide/cobalt hydroxide, etc., can solve the problems of easy agglomeration, poor adsorption capacity of organic pollutants, and low catalytic efficiency, etc. The operation method is simple and the synthesis time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

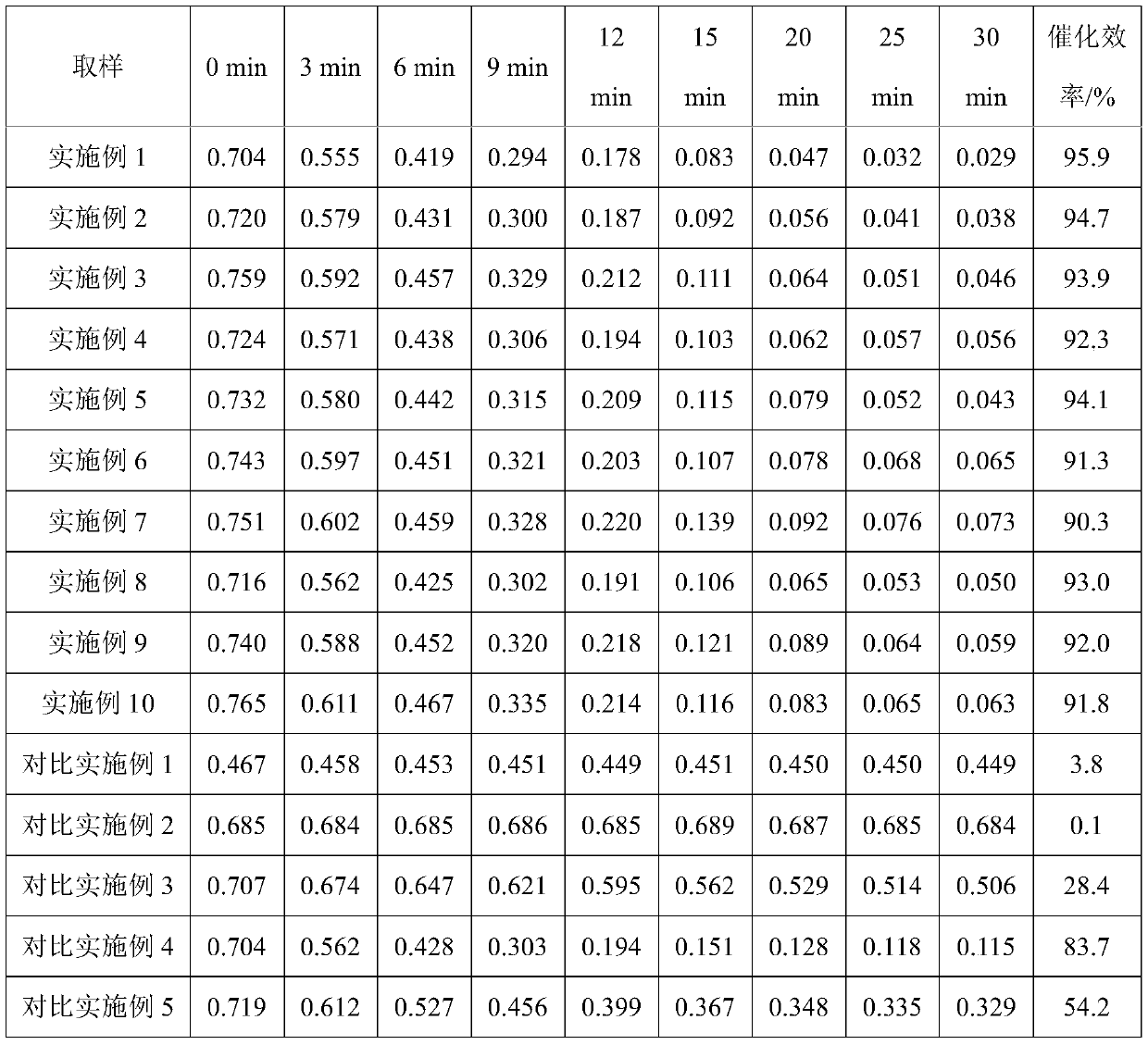

Embodiment 1

[0043] The following method is adopted to prepare the composite photocatalyst Ag / AgCl@Co according to the present invention 3 o 4 :

[0044] (1) The methanol (100mL) solution of 2-methylimidazole (6.489g, 0.08mol) was mixed rapidly with the methanol (100mL) solution of cobalt nitrate hexahydrate (2.933g, 0.01mol), and the Stirring for 5 hours, after the reaction was completed, the resulting mixture was centrifuged, washed three times with methanol, and dried at 60°C to obtain ZIF-67;

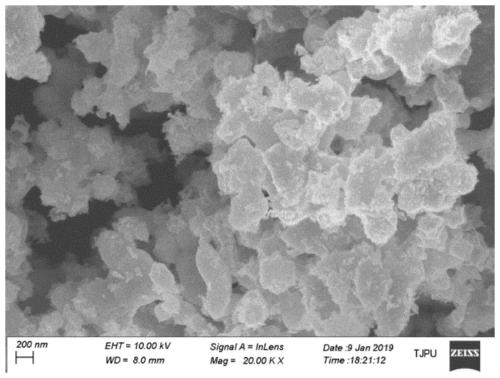

[0045] (2) calcining the ZIF-67 prepared in step (1) in a muffle furnace at a temperature of 400°C for 2 hours to obtain Co 3 o 4 nanoparticles;

[0046] (3) Take the Co 3 o 4 Nanoparticles (50mg) were added into methanol (20mL) and ultrasonically dispersed until completely dispersed to prepare Co 3 o 4 suspension;

[0047] (4) to the Co 3 o 4 Silver nitrate (0.3737g, 0.0022mol) was added to the suspension, and stirred for 0.5 hours under dark conditions to obtain a mixed suspension; ...

Embodiment 2

[0050] The following method is adopted to prepare the composite photocatalyst Ag / AgCl@Co according to the present invention 3 o 4 :

[0051] (1) The methanol (100mL) solution of 2-methylimidazole (6.489g, 0.08mol) was mixed rapidly with the methanol (100mL) solution of cobalt nitrate hexahydrate (2.933g, 0.01mol), and the Stirring for 5 hours, after the reaction was completed, the resulting mixture was centrifuged, washed three times with methanol, and dried at 60°C to obtain ZIF-67;

[0052] (2) calcining the ZIF-67 prepared in step (1) in a muffle furnace at a temperature of 500°C for 2 hours to obtain Co 3 o 4 nanoparticles;

[0053] (3) Take the Co 3 o 4 Nanoparticles (50mg) were added into methanol (20mL) and ultrasonically dispersed until completely dispersed to prepare Co 3 o 4 suspension;

[0054] (4) to the Co 3 o 4 Silver nitrate (0.3737g, 0.0022mol) was added to the suspension, and stirred for 0.5 hours under dark conditions to obtain a mixed suspension; ...

Embodiment 3

[0057] The following method is adopted to prepare the composite photocatalyst Ag / AgCl@Co according to the present invention 3 o 4 :

[0058] (1) The methanol (100mL) solution of 2-methylimidazole (7.398g, 0.09mol) was mixed rapidly with the methanol (100mL) solution of cobalt nitrate hexahydrate (2.619g, 0.009mol), and the Stirring for 5 hours, after the reaction was completed, the resulting mixture was centrifuged, washed three times with methanol, and dried at 60°C to obtain ZIF-67;

[0059] (2) Calcinate the ZIF-67 prepared in step (1) in a muffle furnace at a temperature of 350° C. for 2 hours to obtain Co 3 o 4 nanoparticles;

[0060] (3) Take the Co 3 o 4 Nanoparticles (40mg) were added into methanol (20mL) and ultrasonically dispersed until completely dispersed to prepare Co 3 o 4 suspension;

[0061] (4) to the Co 3 o 4 Silver nitrate (0.4417g, 0.0026mol) was added to the suspension, and stirred for 0.5 hours under dark conditions to obtain a mixed suspensio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap