Cleaning method of target material

A technology of target material and cleaning agent, applied in the cleaning method using liquid, cleaning method using gas flow, cleaning method and utensils, etc., can solve the problem of affecting the sputtering effect, scratches on the sputtering surface, and difficulty in guaranteeing the surface finish of the product and other problems to achieve the effect of improving the cleaning effect and improving the finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] At present, the conventional target cleaning technology, for example, manually wipes and cleans the target with a cleaning cloth, which is not only difficult to ensure the cleanliness, but also, the cleaning cloth produces friction on the surface of the product, which easily scratches the surface of the product and makes the surface of the target not smooth enough. Bright and clean, can not meet the requirements of the sputtering process.

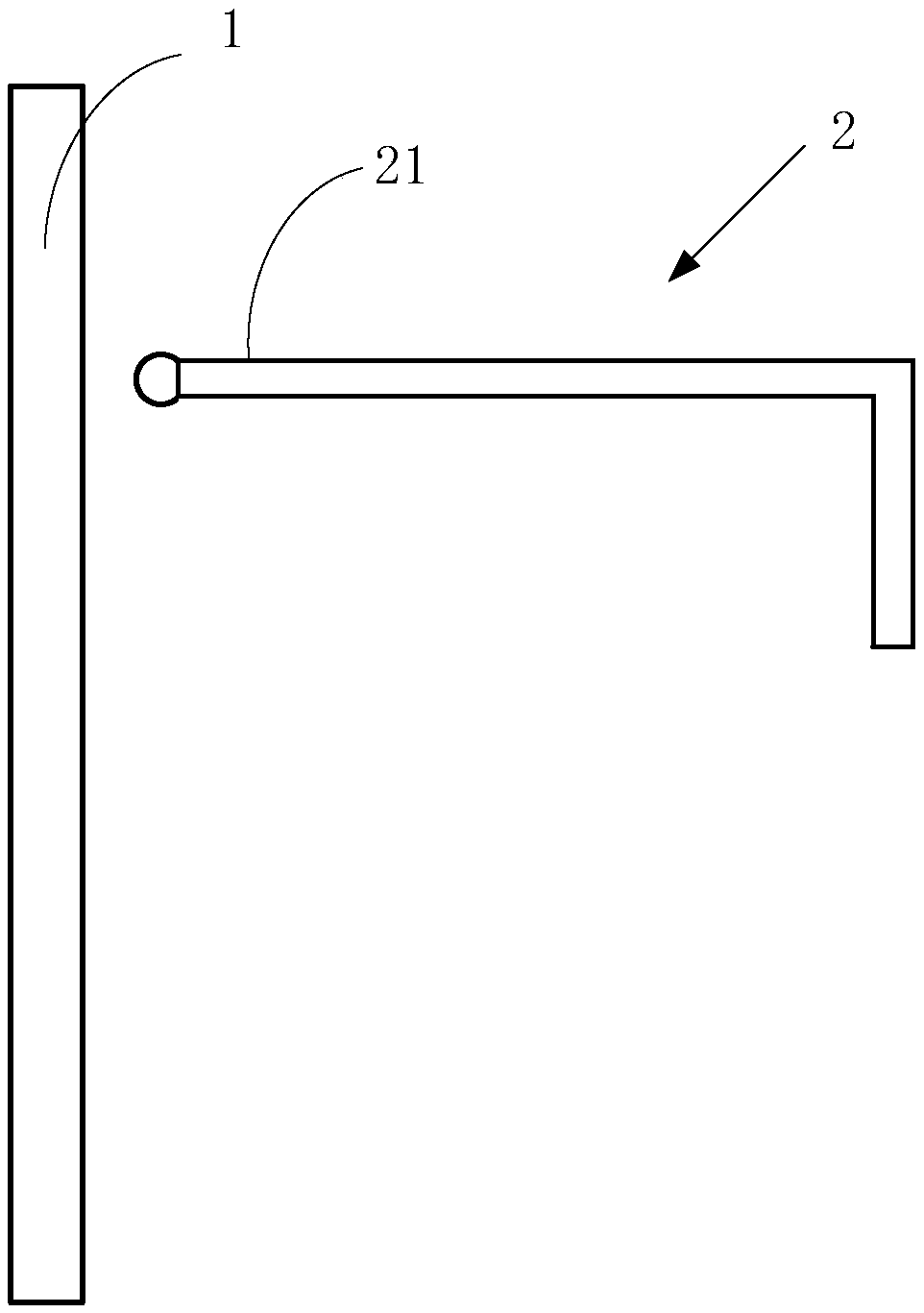

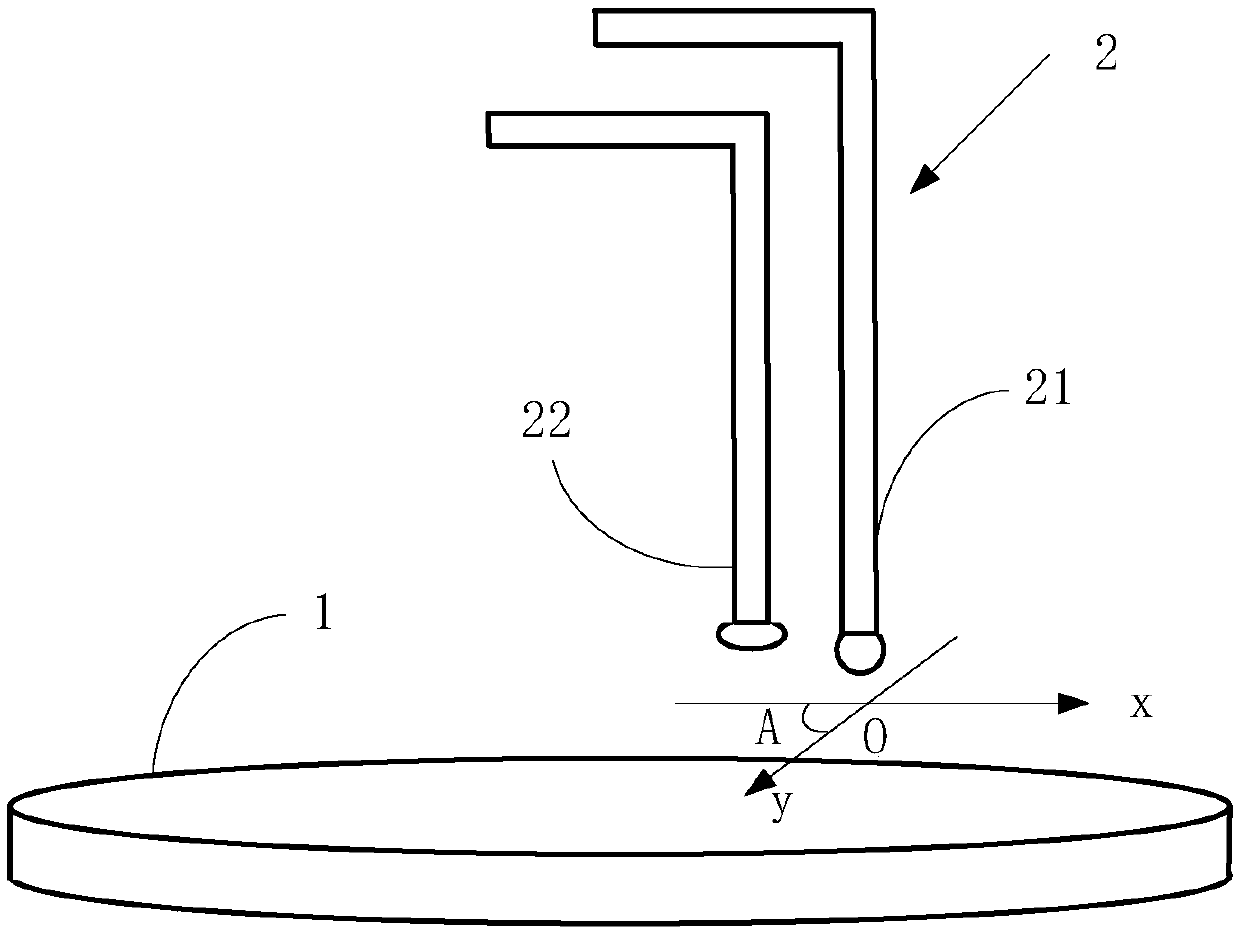

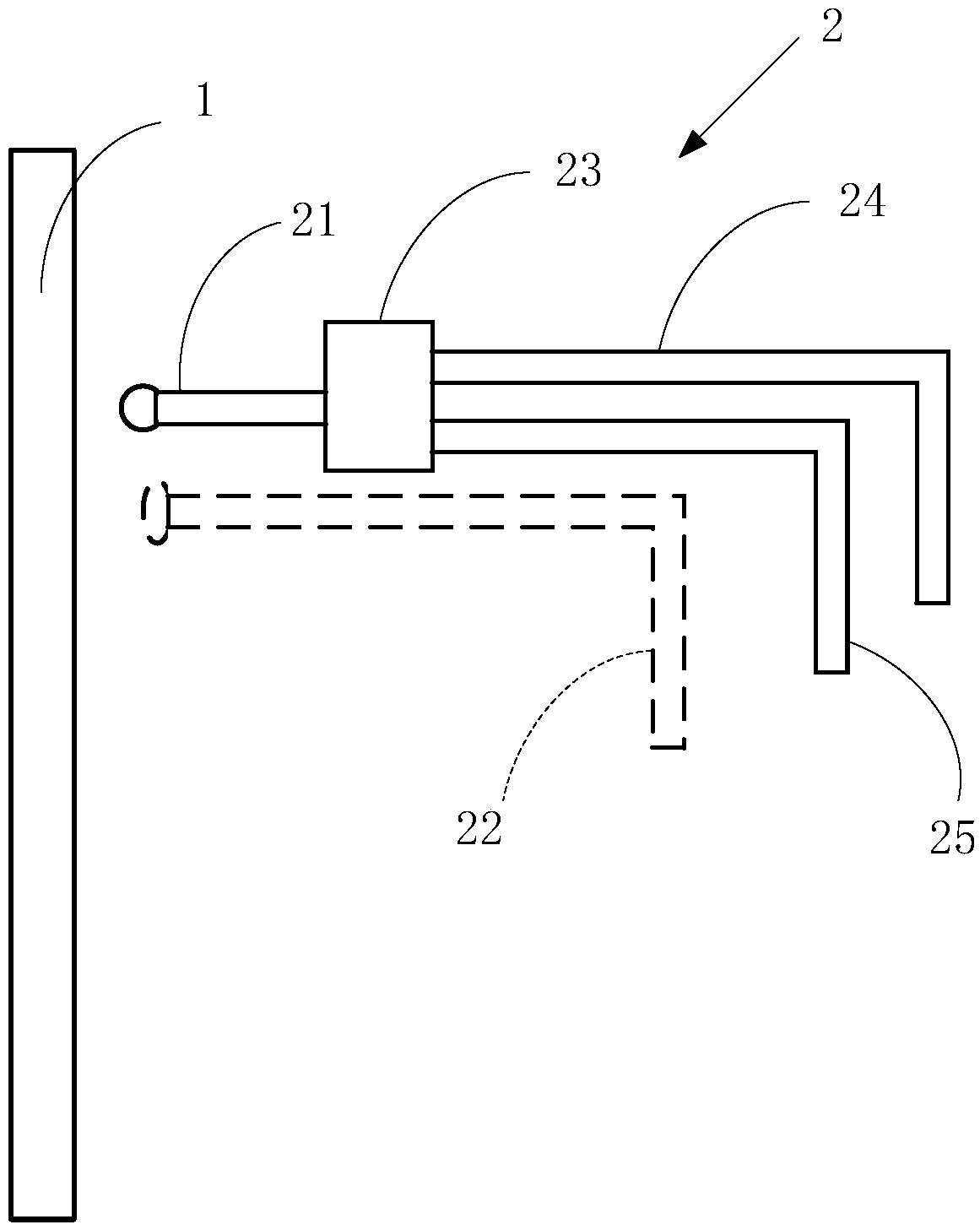

[0025] In order to overcome the above-mentioned defects, the inventor conducted research and found that spraying a cleaning agent on the surface of the target material for cleaning does not generate friction during the cleaning process, which effectively solves the problem of surface scratches caused by the target material during the cleaning process. The smoothness of the target surface is improved; and the cleaning effect can be improved by adjusting various parameters during spraying.

[0026] In order to make the above objects, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com