Gear ring casting method for avoiding local slurry lacking phenomenon

A ring gear and phenomenon technology, which is applied in the field of ring gear casting for local lack of slurry, can solve the problems of lack of slurry in the template, insufficient slurry filling, and inability to put into use, so as to reduce local lack of slurry, facilitate recycling, High usability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

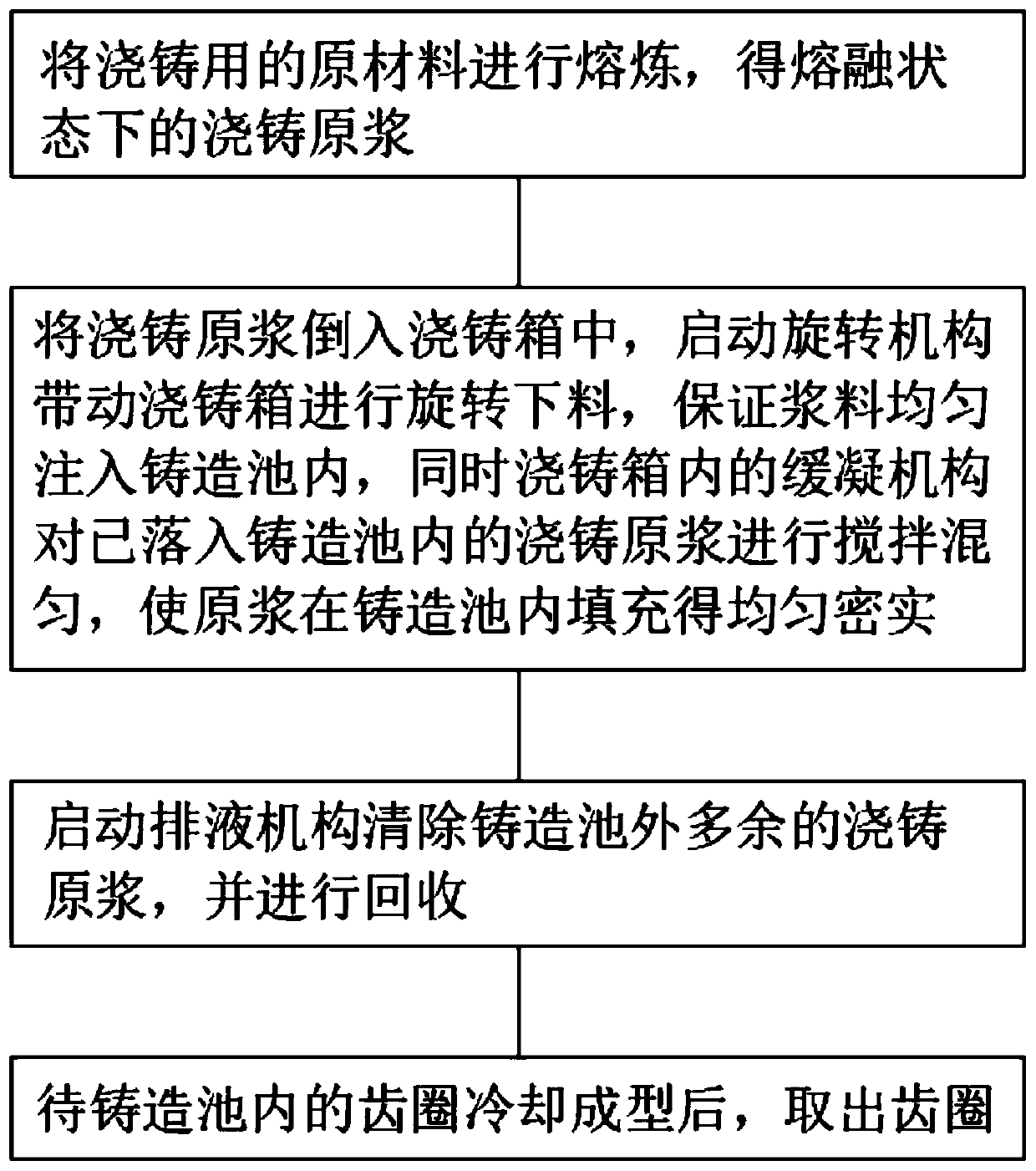

[0048] see figure 1 , a ring gear casting method aimed at the phenomenon of partial lack of pulp, comprising the following steps:

[0049] S1. The technicians melt the raw materials for casting to obtain the casting raw slurry in the molten state;

[0050] S2. Pour the casting raw slurry into the casting box, start the rotating mechanism to drive the casting box to rotate and unload the material, to ensure that the slurry is evenly injected into the casting pool, and at the same time, the retarding mechanism in the casting box controls the casting raw slurry that has fallen into the casting pool. Stir and mix well, so that the original slurry is filled evenly and densely in the casting pool;

[0051] S3, start the liquid discharge mechanism to remove the excess casting raw slurry outside the casting pool, and recycle it;

[0052] S4. After the ring gear in the casting pool is cooled and formed, take out the ring gear.

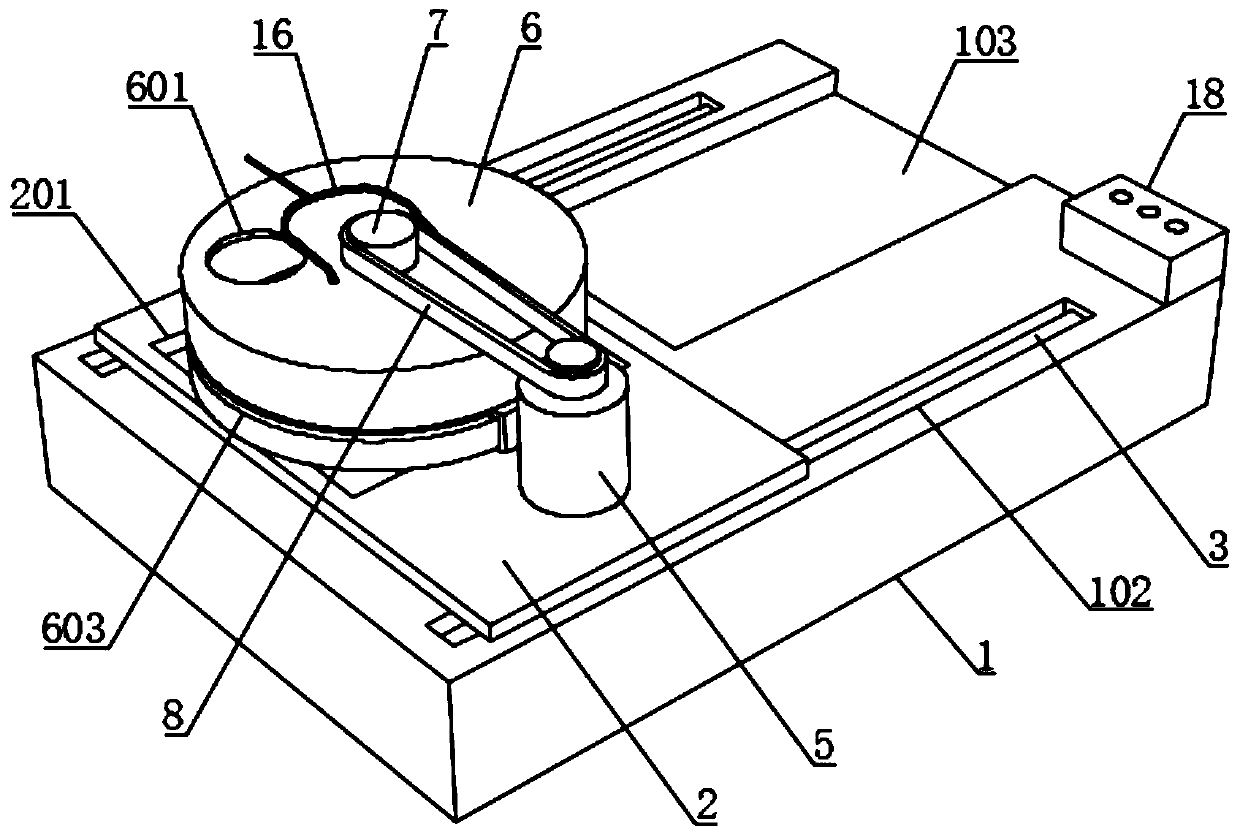

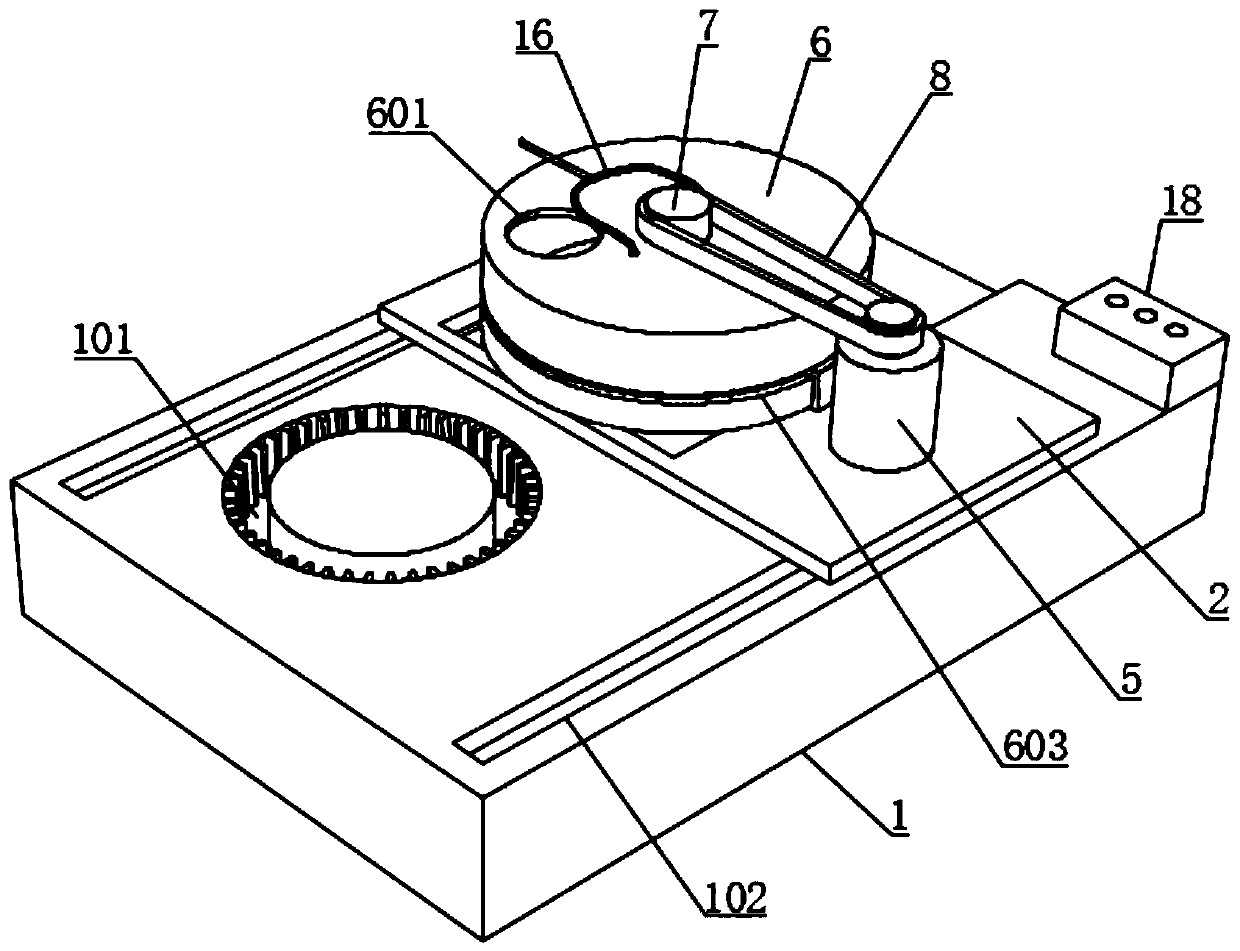

[0053] see figure 2 and image 3 , the casting pool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com