Zirconium tube for zirconia oxygen analyzer and preparation method of zirconium tube

An oxygen analyzer and zirconia technology, applied in the field of instrument analysis, can solve the problems of low density and strength of zirconium tubes, poor product consistency, poor thermal shock resistance, etc., and achieve good electrical conductivity and thermal shock resistance, forming and The sintering process is stable and easy to control, and the effect of high bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

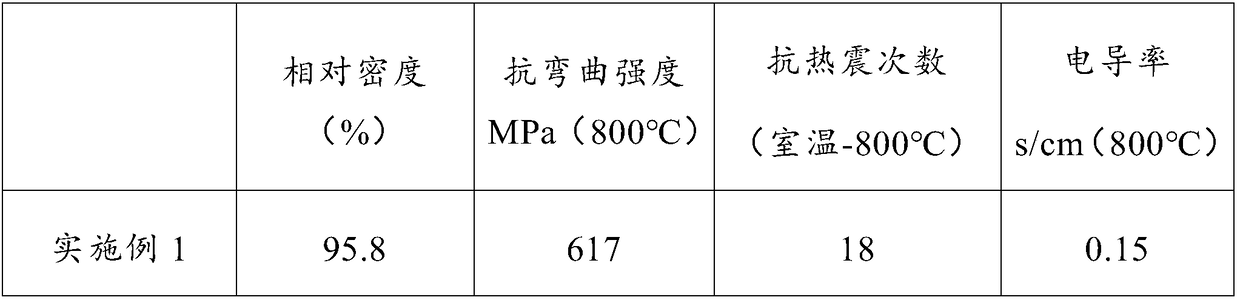

[0036] Embodiment 1: Preparation of zirconium tube for zirconia oxygen analyzer (1)

[0037] Will Y 2 o 3 Dissolved with hot nitric acid and ZrOCl 2 and Al(NO 3 ) 3 The solution is mixed evenly, and the molar ratio of the three is 8:91.5:1. Precipitant ammonia water was added, and the resulting precipitate was washed with deionized water and ethanol solution, freeze-dried, ground, and then calcined (at a temperature of 700°C for 3 hours), and the calcined product was added with a binder to be ground and granulated. Put the ground and granulated powder on a vibration platform with a vibration frequency of 25 Hz (ZP-0.5ⅹ0.5 type, Xinxiang No. 1 Vibration Machinery Factory) into a rubber mold with a designed size and fill it with vibration. Then put the rubber mold filled with zirconia powder into a cold isostatic press (LDJ200 / 1000-300 type, Chuanxi Machine Factory), and press isostatically under a pressure of 180 MPa to obtain a zirconium tube biscuit. Then place the obta...

Embodiment 2

[0038] Embodiment 2: Preparation of zirconium tubes for zirconia oxygen analyzer (two)

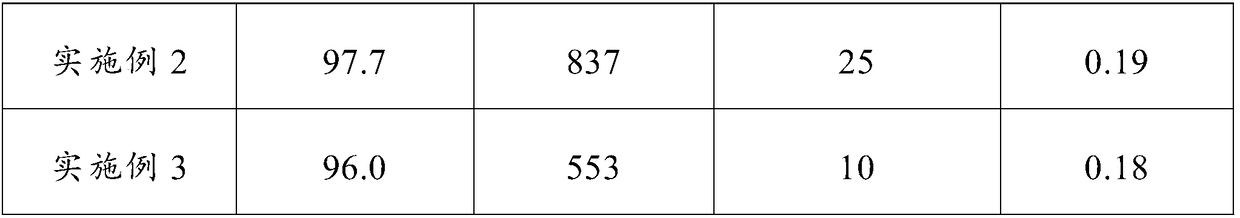

[0039] Will Y 2 o 3 Dissolved with hot nitric acid and ZrOCl 2 and Al(NO 3 ) 3The solution is mixed evenly, and the molar ratio of the three is 8:90.5:3. Precipitant ammonia water was added, and the obtained precipitate was washed with deionized water and ethanol solution, freeze-dried, ground, and then calcined (at a temperature of 800° C. for 2 hours), and the calcined product was added with a binder to be ground and granulated. Put the ground and granulated powder into a rubber mold with a designed size on a vibration equipment with a vibration frequency of 28 Hz (ZP-0.5ⅹ0.5 type, Xinxiang No. 1 Vibration Machinery Factory) and fill it with vibration. Then put the rubber mold filled with zirconia powder into a cold isostatic press (LDJ200 / 1000-300 type, Chuanxi Machine Factory), and press isostatically under a pressure of 190 MPa to obtain a zirconium tube biscuit. Then place the ...

Embodiment 3

[0040] Embodiment 3: Preparation of zirconium tubes for zirconia oxygen analyzer (three)

[0041] Will Y 2 o 3 Dissolved with hot nitric acid and ZrOCl 2 and Al(NO 3 ) 3 The solution is mixed evenly, and the molar ratio of the three is 8:89:6. Precipitant ammonia water was added, and the resulting precipitate was washed with deionized water and ethanol solution, freeze-dried, ground, and then calcined (at a temperature of 900° C. for 1 h), and the calcined product was added with a binder to be ground and granulated. Put the ground and granulated powder on a vibration platform with a vibration frequency of 30 Hz (ZP-0.5ⅹ0.5 type, Xinxiang No. 1 Vibration Machinery Factory) into a rubber mold with a designed size and fill it with vibration. Then put the rubber mold filled with zirconia powder into a cold isostatic press (LDJ200 / 1000-300 type, Chuanxi Machine Factory), and press isostatically under a pressure of 200 MPa to obtain a zirconium tube biscuit. Then place the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com