Water spraying transportation box with self-spraying function

A transport box and water spray technology, applied in the field of transport boxes, can solve problems such as increased transport loss, insufficient oxygen content, and reduced air oxygen content, and achieve the effects of improving collision effect, increasing contact area, and improving atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

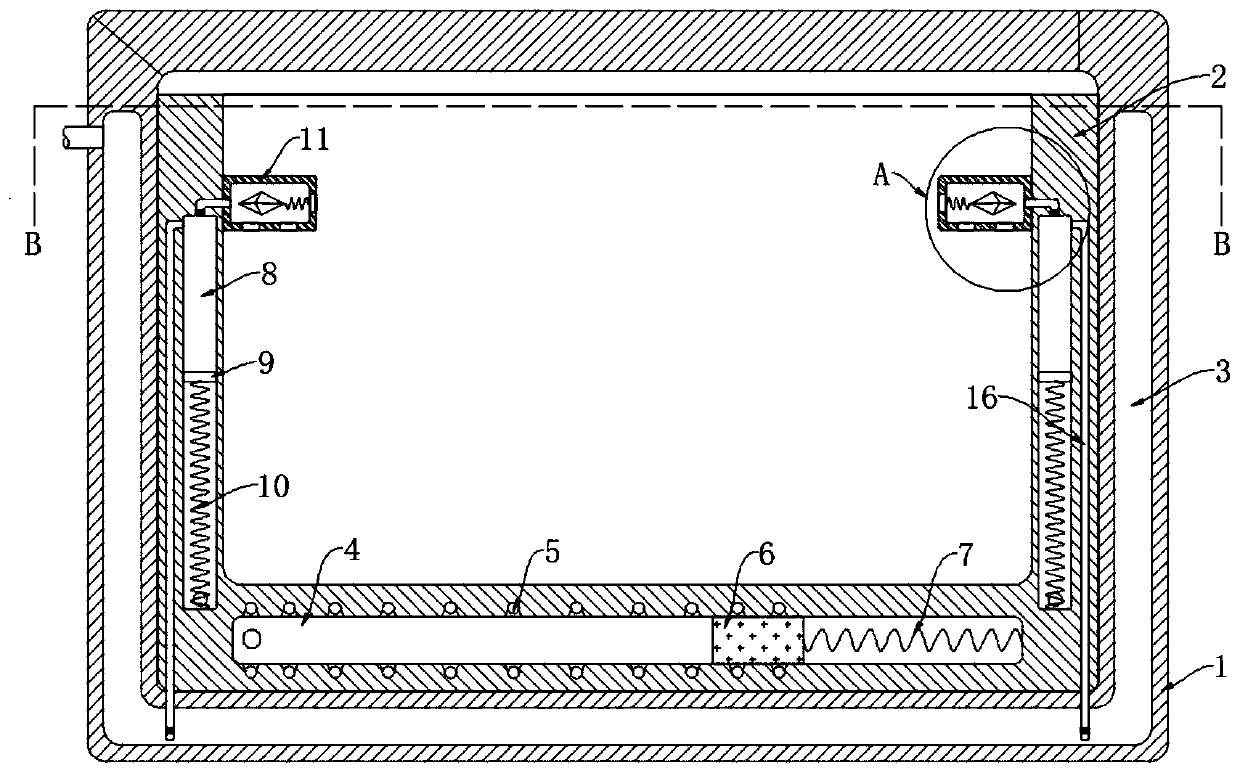

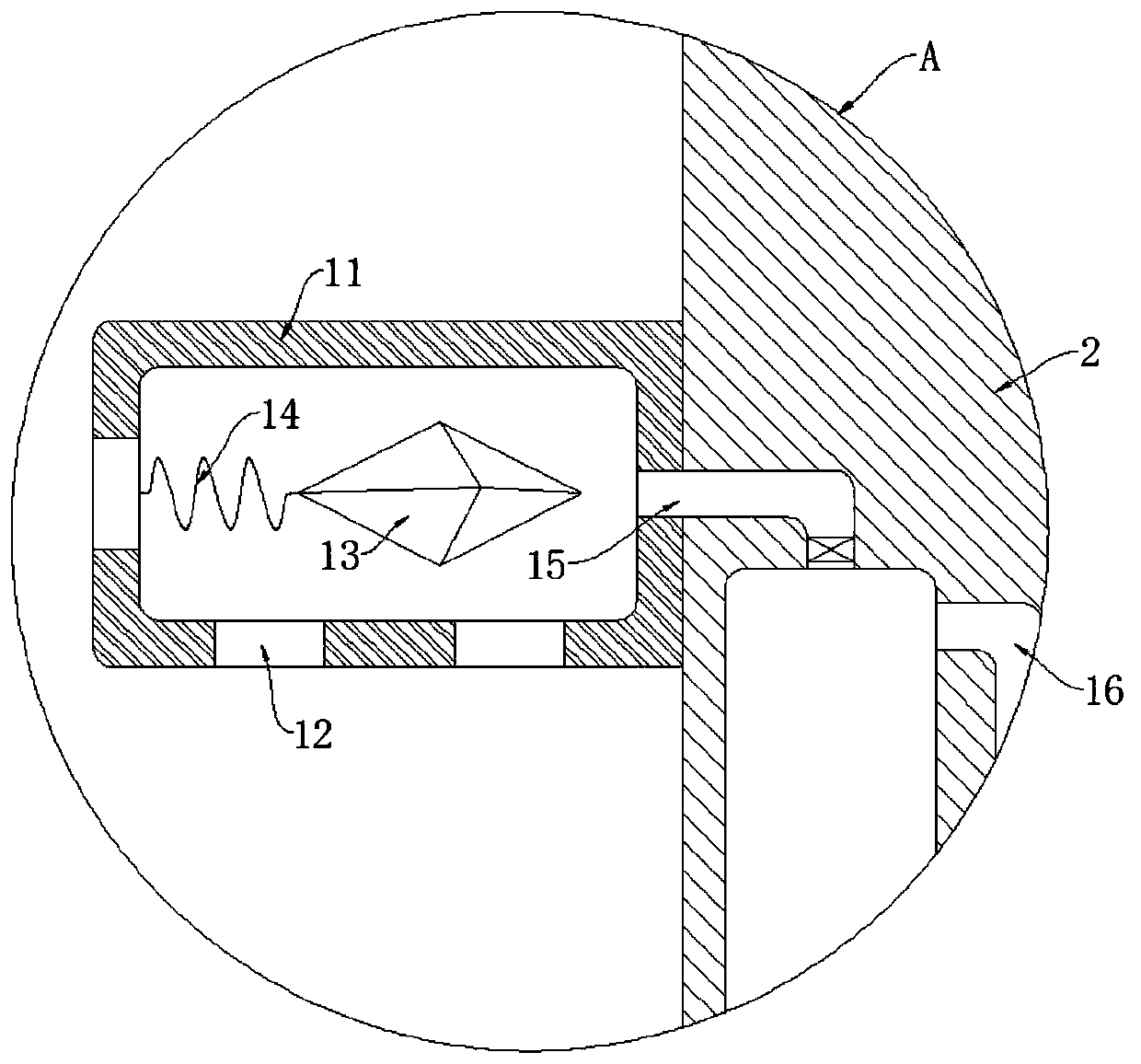

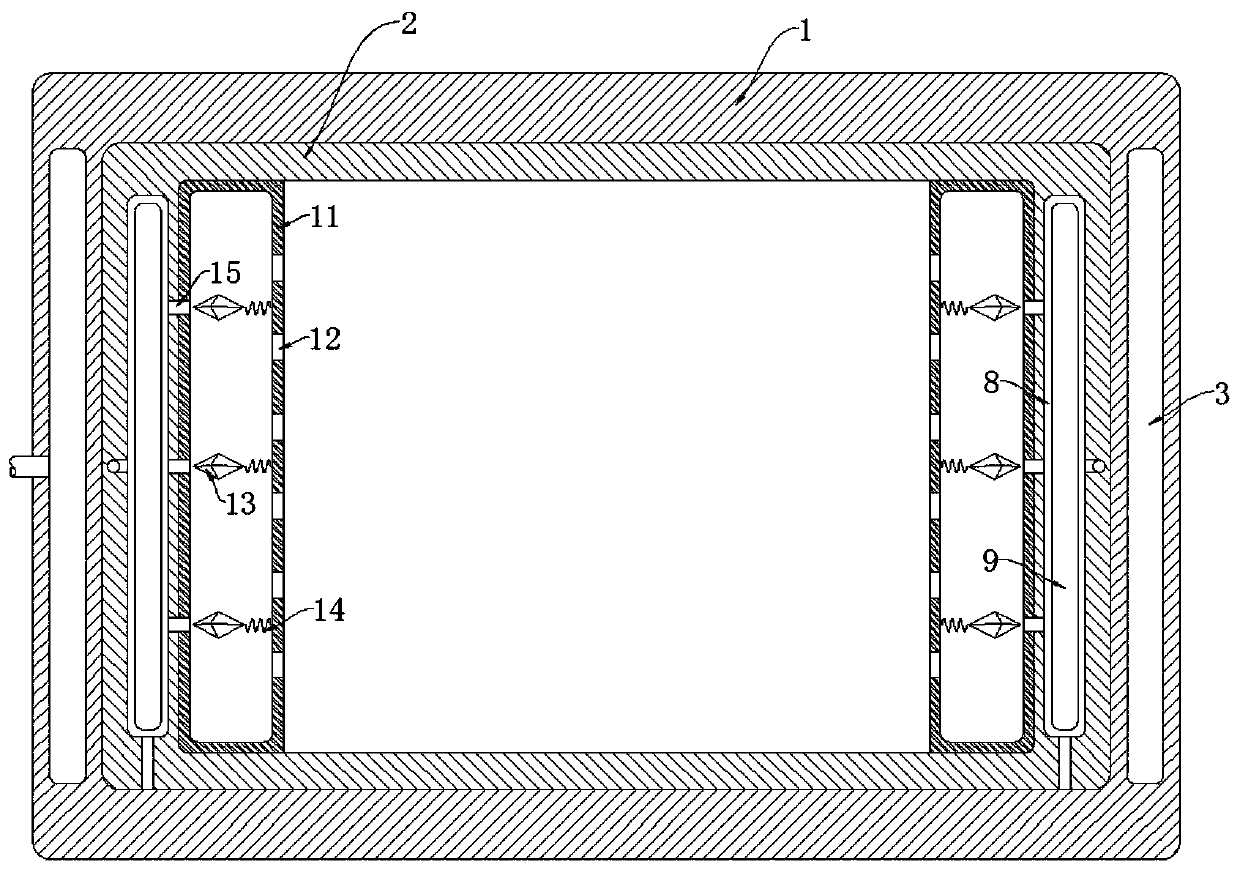

[0022] refer to Figure 1-3 , a water spray transport box with self-spraying function, comprising a sealed box 1, a fixed box 2 is fixedly connected to the inner bottom of the sealed box 1, a water storage chamber 3 is fixedly provided on the inner wall of the sealed box 1, and a water storage chamber 3 is provided on the side wall of the sealed box 1. The inner wall of the water storage chamber 3 is connected to the water inlet pipe, which is convenient for replenishing sea water in time. A cavity 4 is provided at the lower end of the fixed box, and an induction coil 5 is embedded in the inner wall of the cavity 4, and the induction coil 5 is arranged unevenly. The spring 7 is elastically connected with the magnet 6. Furthermore, when the vehicle is running smoothly, the magnet 6 will not move in the cavity 4. Since the induction coil 5 is unevenly arranged, according to the principle of magnetic induction, when the magnet 6 slides on the inner wall of the cavity 4 , the magn...

Embodiment 2

[0025] refer to Figure 4 , different from Embodiment 1, positive electrode sheet 17 and negative electrode sheet 18 are respectively installed on the opposite inner wall of water storage chamber 3, and positive electrode sheet 17 and negative electrode sheet 18 are coupled and connected with the positive and negative poles of induction coil 5, and the positive electrode sheet Seawater can be electrolyzed into hydrogen and oxygen after being energized on 17 and negative electrode sheet 18, is prior art, and the top in water storage chamber 3 communicates with the inner wall of sealed box 1 through first air outlet chamber 19, and water storage chamber 3 is far away from the first air outlet The inner top of the cavity 19 communicates with the side wall of the sealed box 1 through the second air outlet cavity 20 .

[0026] In this embodiment, when the magnet 6 moves back and forth in the cavity 4, the induced current generated on the induction coil 5 embedded in the inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com