A kind of slag accumulating cooling device and working method under the furnace

A cooling device and slag technology, applied in the manufacture of converters, etc., can solve the problems of wheels falling off the track, reducing equipment life, and rail thickening, so as to prevent adhesion on the rail, reduce equipment loss, and ensure smooth production line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

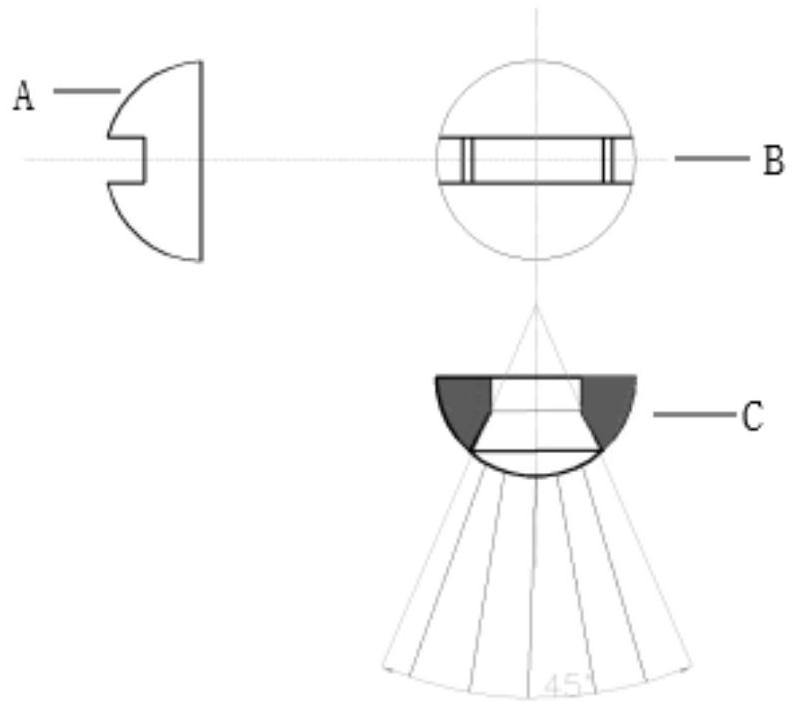

[0060] A kind of nozzle, described nozzle comprises a channel, and the cross-section of described channel is isosceles trapezoid, and the included angle of two waists of described trapezoid is 45 °, and the height of described channel is 2mm, and the upper base of described trapezoid The length is 10 mm, and the distance between the two bases of the trapezoid is 6 mm.

[0061] The end with a small opening at the end of the channel is a fluid inlet.

[0062] The channel fluid inlet is connected to a cylindrical channel structure.

[0063] The nozzle is made of metal copper.

[0064] The schematic diagram of the nozzle is shown in image 3

[0065] In the figure: A is a side schematic diagram, B is a front schematic diagram, and C is a cross-sectional schematic diagram

Embodiment 2

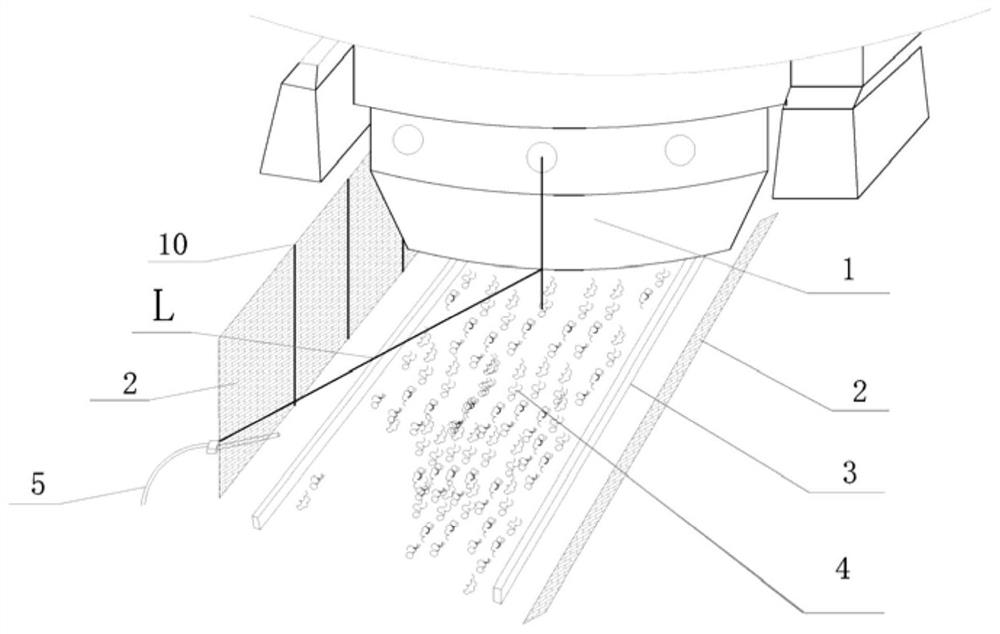

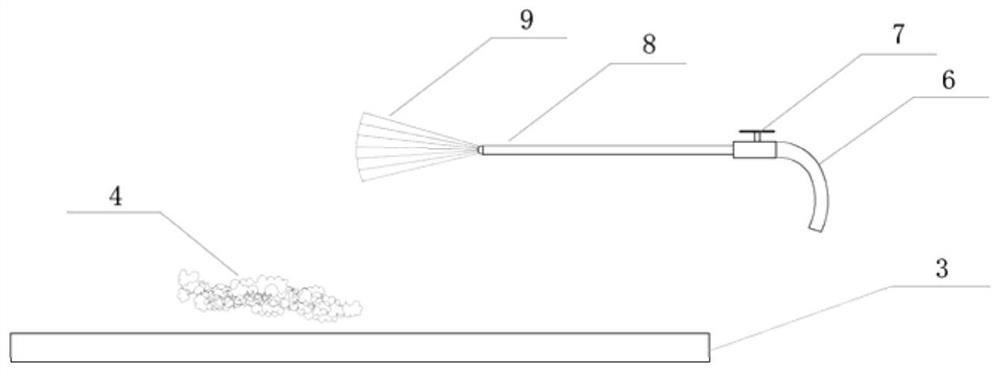

[0067] A slag cooling device, comprising a fire-retaining wall (2), a liquid spraying device (5), the liquid spraying device (5) comprising a liquid spraying rod (8), an infusion tube (6), and a control device (7), the The liquid spray rod (8) is arranged on the fire-retaining wall (2), on the rail (3) side of the fire-retaining wall (2), and the liquid outlet at the end of the rod body of the liquid spray rod (8) is provided with a In the nozzle, the liquid inlet at the end of the spray rod (8) is connected to the infusion tube (6), and the other end of the infusion tube (6) passes through the fire wall (2) and is connected to the liquid storage device; The height of the liquid spray rod (8) horizontally away from the track (3) is 1.5m, and a control device (7) is connected between the infusion pipe (6) and the liquid spray rod (8) to control the liquid pressure; see figure 1 , figure 2 .

[0068] The rod inner diameter of the liquid spray rod is Φ15mm.

[0069] The rod b...

Embodiment 3

[0074] A furnace body device equipped with the slag cooling device described in Embodiment 2, comprising: a fire-retaining wall (2), a liquid spray device (5), and a furnace body (1); the liquid spray device (5) includes a liquid spray rod (8), infusion tube (6), control device (7), the liquid spray rod (8) is arranged on the fire-retaining wall (2), and is arranged on the rail (3) side of the fire-retaining wall (2), the described The liquid outlet at the end of the rod body of the spray rod (8) is provided with the nozzle described in Embodiment 1, the liquid inlet at the end of the rod body of the liquid spray rod (8) is connected to the infusion tube (6), and the infusion tube (6) ) passes through the fire wall (2) and is connected with the liquid storage device; the height of the horizontal distance track (3) of the liquid spray rod (8) is 1.5m, between the infusion pipe (6) and the liquid spray rod (8 ) is connected with a control device (7), used to control the liquid p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com