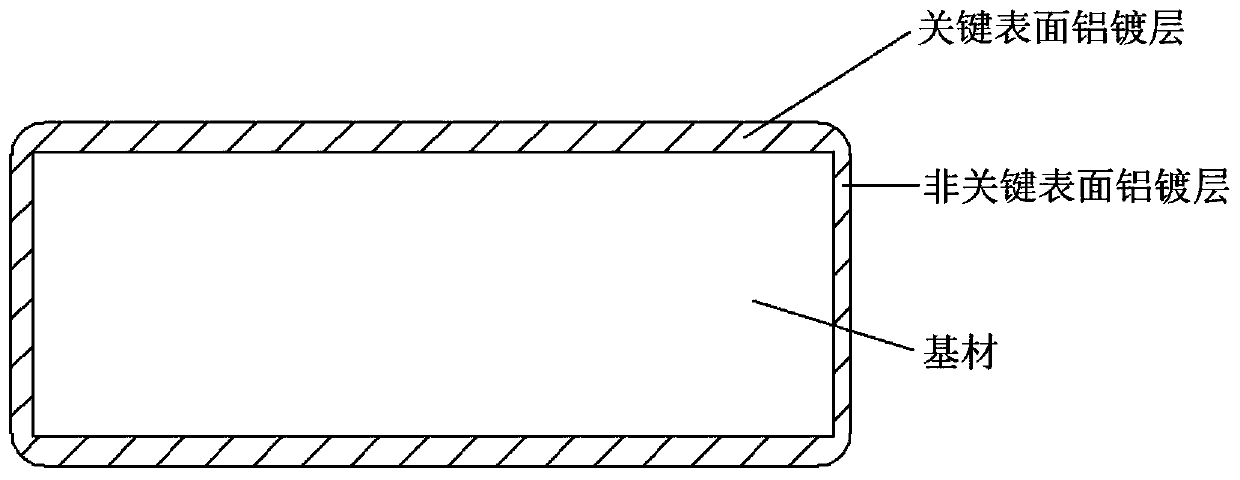

GS sheet product capable of realizing full coverage of aluminum spraying by brand-new spraying method

A full-coverage and full-coverage technology, applied in the direction of pressure inorganic powder coating, etc., can solve the problems of short life and easy corrosion of old GS chips, and achieve the effect of prolonging the service life and avoiding the corrosion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

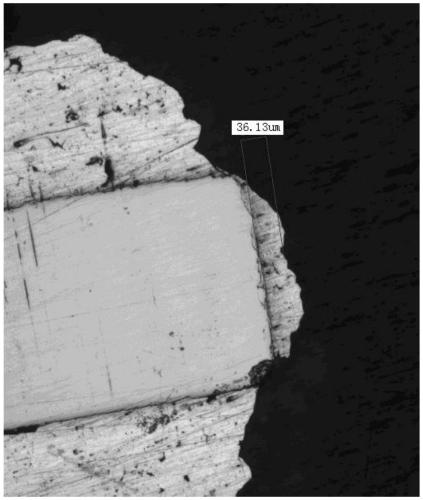

[0019] First, use a substrate sample of 300*150*0.2mm, line-spray the upper and lower surfaces with a thickness of 100-120um, and then spray the side with a thickness of 20-40um. Finally, an electron microscope was used to examine the coating coverage and film thickness.

[0020] Using the new spraying process method, observe the sample under the electron microscope, figure 2 It can be observed that the coating has been completely covered around the part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com